Thickening composition for glufosinate and Chipton, and preparation and application thereof

A technology of dimethyltetrachloride and composition, which is applied in the field of pesticide chemistry, can solve the problems of easy delamination, poor stability, and affecting the weeding effect, and achieve the effect of improving adhesion, improving the effect of use, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The configuration method of thickening composition 1 is as follows: put 12 grams of ammonium pyrrolidinedithiocarbamate and 180 grams of surfactant A1 into a 1 kg reactor, then pump in 808 grams of water, start stirring, and heat up to 45°C. Stir for 20 minutes until the solid is completely dissolved, then add 20 g of ammonium chloride, and stir for 20 minutes to achieve a uniform system to obtain thickening composition 1.

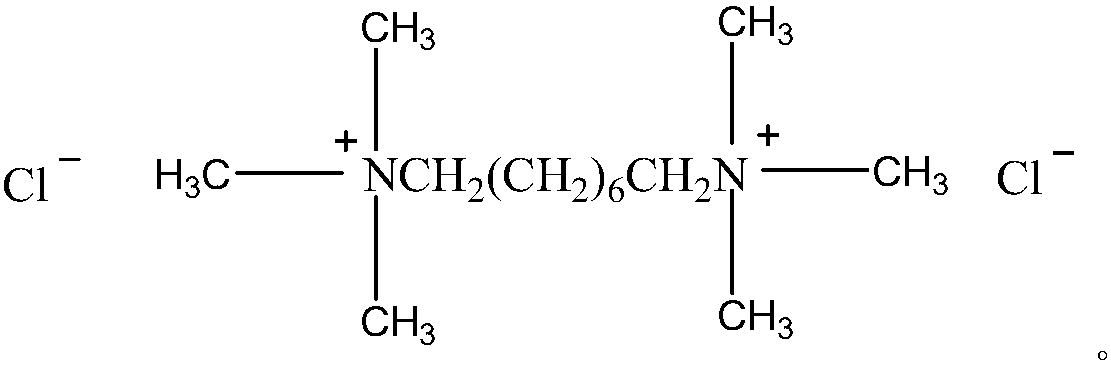

[0026] Wherein the structural formula of surfactant A1 is as follows:

[0027]

Embodiment 2

[0029] The configuration method of thickening composition 2 is as follows: put 25 grams of ammonium pyrrolidine dithiocarbamate, 350 grams of surfactant A2 and 200 grams of surfactant B1 into a 1 kg reactor, then pump in 425 grams of water, and start Stir, heat up to 45°C, stir for 20 minutes until the solids are completely dissolved, then add 20 g of ammonium sulfate, stir for 20 minutes until a homogeneous system is obtained, and thickening composition 2 is obtained.

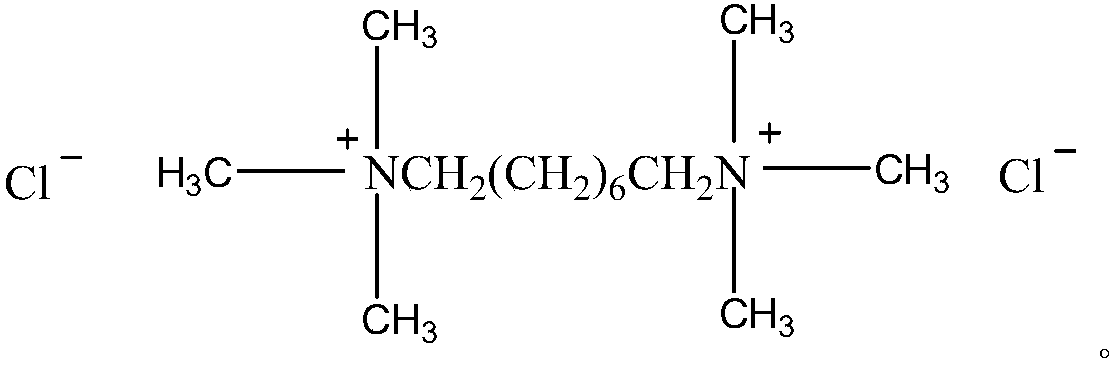

[0030] Wherein the structural formula of surfactant A2 is as follows:

[0031]

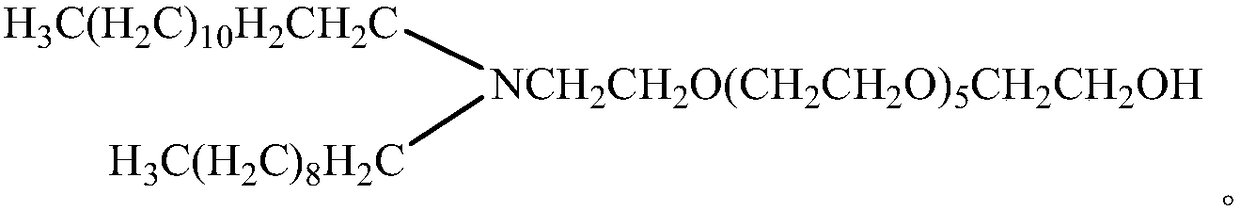

[0032] The structural formula of surfactant B1 is as follows:

[0033]

Embodiment 3

[0035] (1) Composition and properties of 18.5% glufosinate-ammonium sodium dimethyltetrachloride aqueous solution

[0036] The 18.5% glufosinate-ammonium dimethyltetrachloride aqueous solution consists of the following components according to the mass percentage:

[0037]

[0038] The properties of 18.5% glufosinate-ammonium dimethyltetrachloride sodium solution are as follows:

[0039]

[0040] Herbicidal efficiency (the total usage of glufosinate-ammonium and sodium dimethyltetrachloride is 200g / ha): 92.1% after 15 days of application; 96.9% after 30 days of application.

[0041] (2) Control agent and performance

[0042] Control drug 1: Compared with the 18.5% glufosinate-ammonium-dimethyltetrachloride aqueous solution in the title (1) of this example, the only difference is that it does not contain thickening composition 1. The viscosity (25°C, rotational viscosity) of the control drug 1 was 12-15 cp.s. Herbicidal efficiency (the total usage of glufosinate-ammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com