Preparation method of zero-adding charcoal-roasted okra bean coffee powder

A technology of coffee powder and zero additives, which is applied in the direction of coffee substitutes, etc., can solve problems such as food safety and impure taste, and achieve the effect of high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

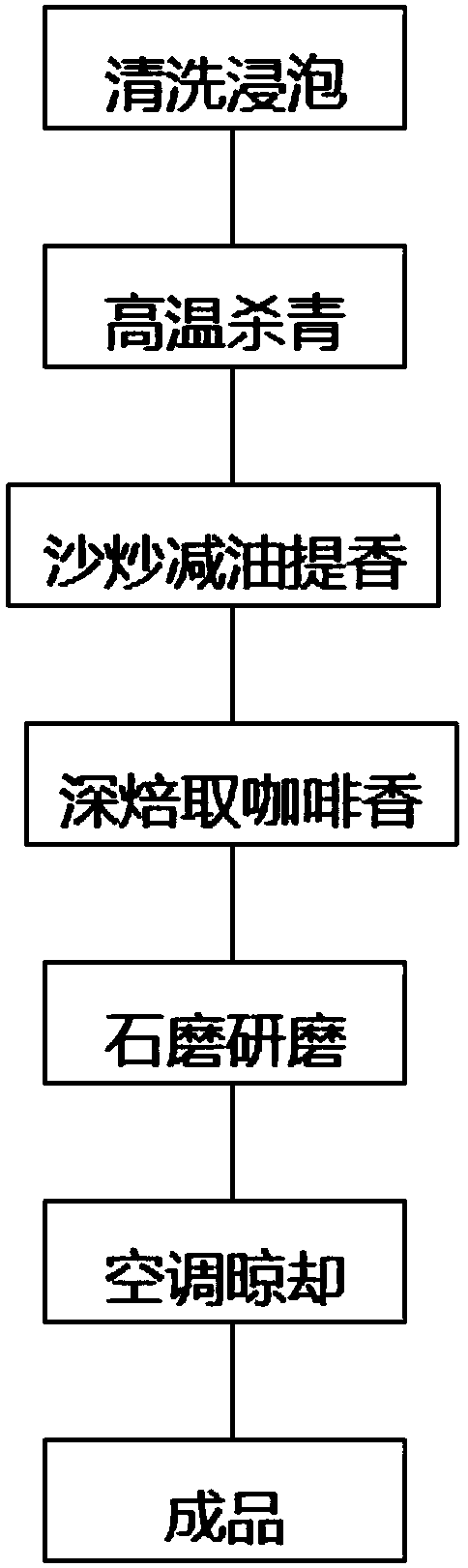

Method used

Image

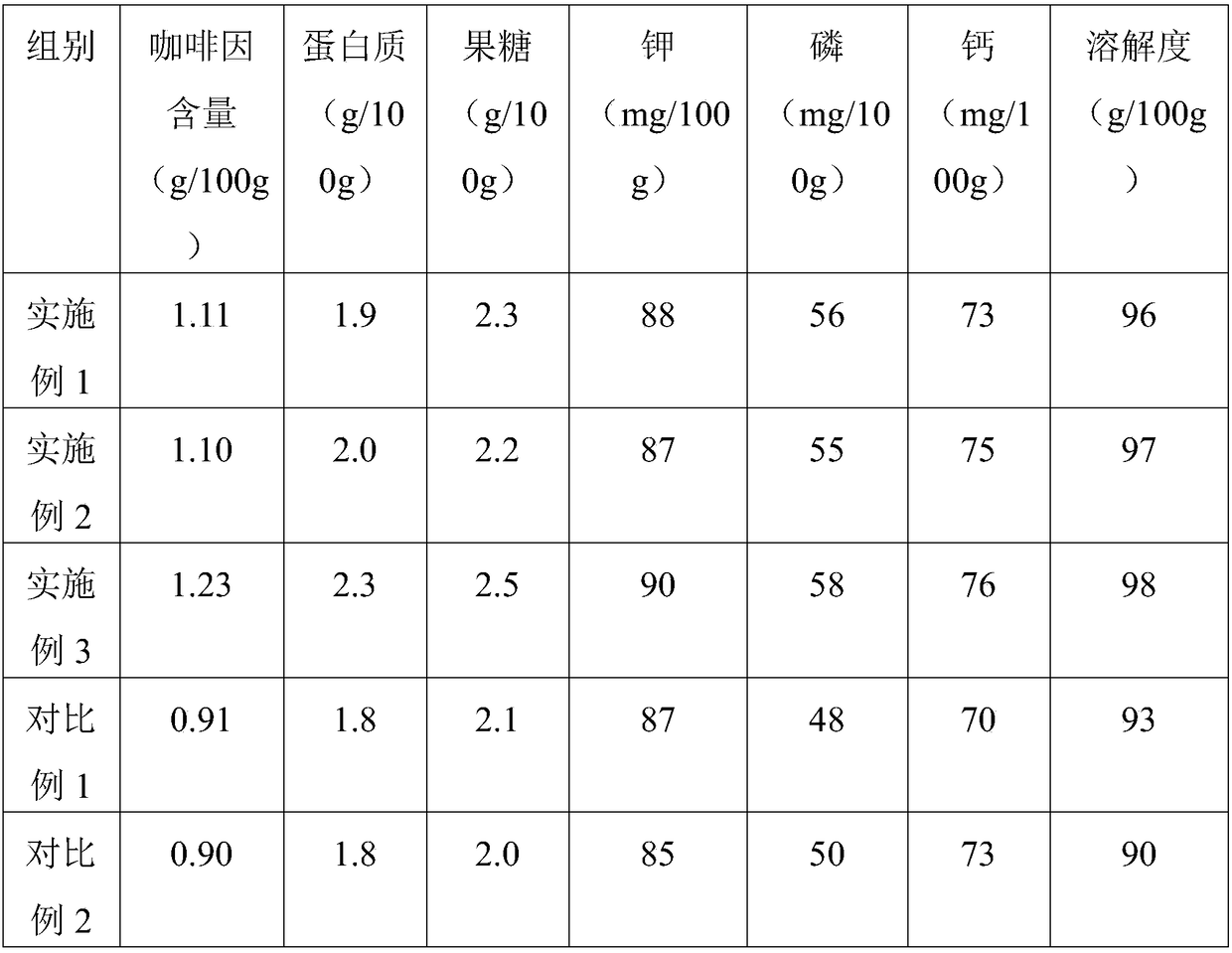

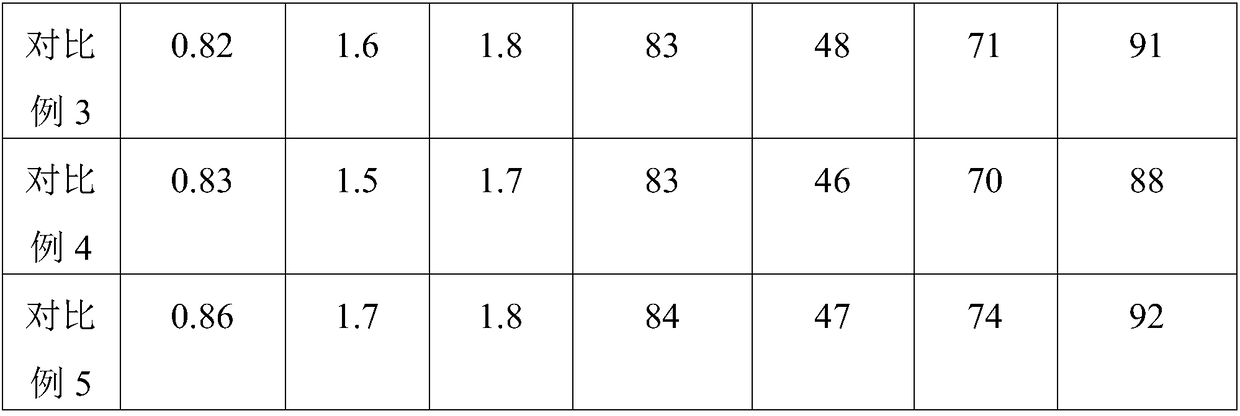

Examples

Embodiment 1

[0031] A preparation method of zero-addition charcoal roasted okra bean coffee powder, comprising the following steps:

[0032] (1) Washing and soaking: Wash the okra beans after the impurity removal treatment, add water to soak for 12 hours, change the water once during the soaking process, and remove the floating okra beans during the soaking process. At this time, the water content of the okra beans is 52~ 53%, air-dried naturally or mechanically, the air-drying temperature is 45°C, and air-dried to a moisture content of 8%.

[0033] (2) High-temperature fixation: put the air-dried okra beans in a fixer for fixation. The fixation is first done at a temperature of 300°C for 10 seconds, and then cooled at a temperature of 125°C for 20 seconds.

[0034] (3) Sand frying to reduce oil and enhance fragrance: Preheat the sand frying machine, preheat the sand frying machine for 0.7 hours, add sand grains and okra beans for sand frying, separate the sand grains and okra beans, and s...

Embodiment 2

[0039] A method for preparing zero-addition charcoal-roasted okra bean coffee powder, comprising the following steps:

[0040] (1) Washing and soaking: Wash the okra beans after the impurity removal treatment, add water to soak for 20 hours, change the water twice during the soaking process, and remove the floating okra beans during the soaking process. At this time, the water content of the okra beans is 52~ 53%, air-dried naturally or mechanically, the air-drying temperature is 50°C, and air-dried to a moisture content of 15%.

[0041] (2) High temperature fixation: put the air-dried okra beans in a fixer for fixation. The fixation is first done at a temperature of 350°C for 15 seconds, and then cooled at a temperature of 138°C for 15 seconds.

[0042] (3) Sand frying to reduce oil and enhance fragrance: Preheat the sand frying machine, preheat the sand frying machine for 1 hour, add sand grains and okra beans for sand frying, separate the sand grains and okra beans, and sti...

Embodiment 3

[0047] A method for preparing zero-addition charcoal-roasted okra bean coffee powder, comprising the following steps:

[0048] (1) Washing and soaking: Wash the okra beans after the impurity removal treatment, add water to soak for 15 hours, change the water twice during the soaking process, and remove the floating okra beans during the soaking process. At this time, the water content of the okra beans is 52~ 53%, air-dried naturally or mechanically, the air-drying temperature is 48°C, and air-dried to a moisture content of 12%.

[0049] (2) High temperature fixation: put the air-dried okra beans in a fixer for fixation. The fixation is first done at a temperature of 330°C for 12 seconds, and then cooled at a temperature of 131°C for 18 seconds.

[0050] (3) Sand frying to reduce oil and enhance fragrance: preheat the sand frying machine, preheat the sand frying machine for 0.85h, add sand grains and okra beans for sand frying, separate the sand grains and okra beans, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com