Special compound feed for paramisgurnus dabryanus and preparation method thereof

A technology of paraloach and compound feed, which is applied in animal feed, animal feed, application, etc., can solve the problems that it is difficult to meet the nutritional needs of paraloach, the growth performance of paraloach is not ideal, and the breeding efficiency is low. Achieve the effects of increasing growth rate and feed conversion rate, high digestion and utilization rate, and improving breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

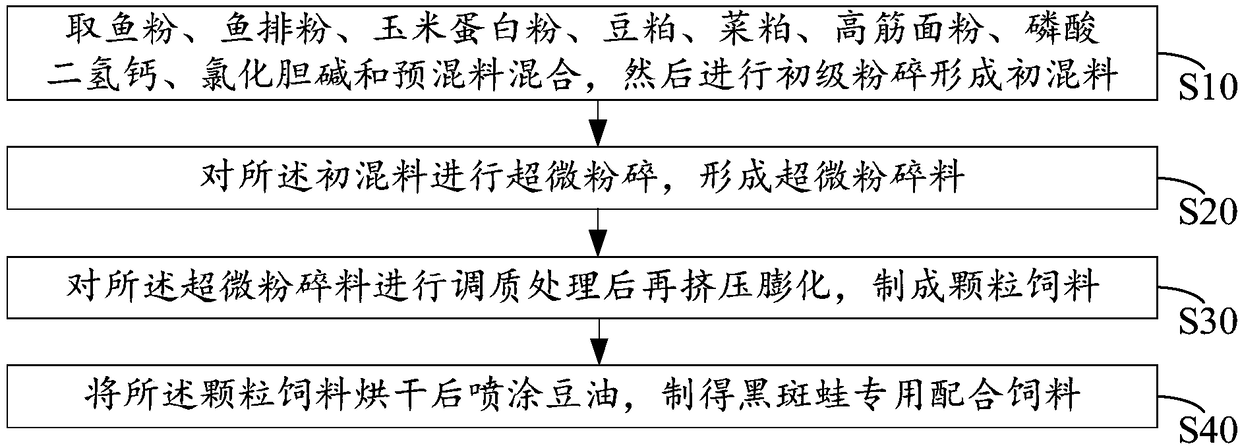

[0032] When feeding the special compound feed for the paraloach, if the sinking speed is too fast, it is easy to cause the feed to be deposited on the bottom of the breeding pond because it is difficult to be fully ingested by the paraloach, resulting in waste of feed, and at the same time It also caused some pollution to water bodies. In order to solve the above problems, the present invention further proposes a method for preparing the above-mentioned special compound feed for P. chinensis, which prepares the special compound feed for P. chinensis by extruding and expanding so that the sinking speed is extremely slow. Floating feed to improve feed utilization and reduce water pollution, figure 1 Shown is an embodiment of the preparation method of the special compound feed provided by the present invention. see figure 1 , in the present embodiment, the preparation method of the special-purpose compound feed of paraloach, described comprises the following steps:

[0033] St...

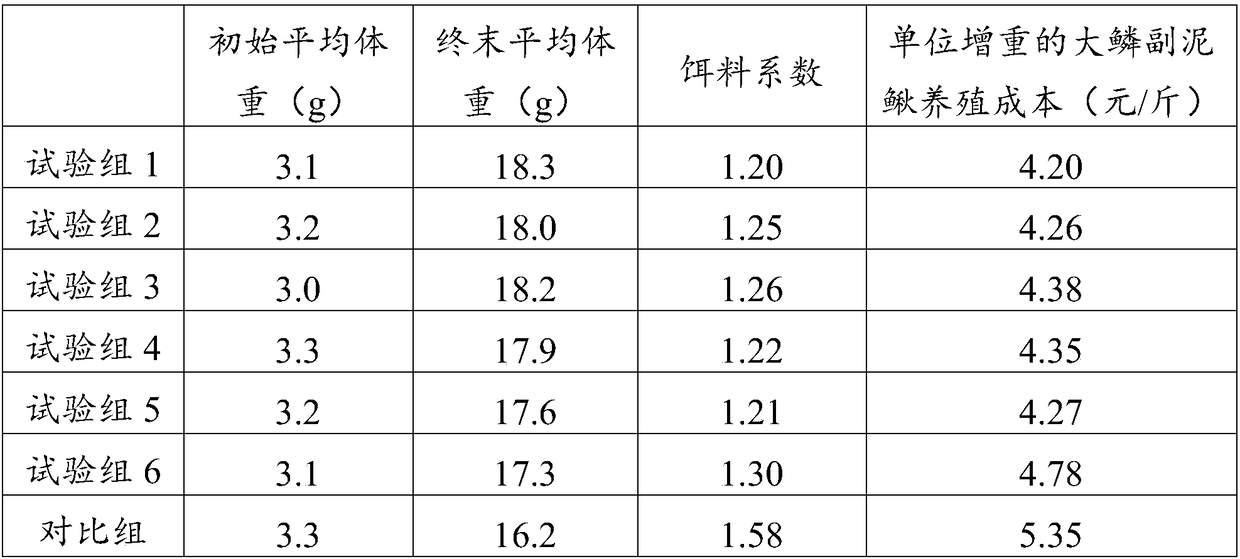

Embodiment 1

[0047] (1) Weighing raw materials: fish meal 19kg, fish steak powder 18kg, corn gluten meal 5kg, soybean meal 28.5kg, rape meal 4.6kg, high-gluten flour 20kg, soybean oil 2kg, calcium dihydrogen phosphate 1.5kg, choline chloride 0.2kg And premix 1.2kg.

[0048] (2) Preparation of feed:

[0049] ① After fully mixing fish meal, fish steak meal, corn gluten meal, soybean meal, rapeseed meal, high-gluten flour, calcium dihydrogen phosphate, choline chloride and premix, grind in a high-speed grinder at a speed of 1500rpm for 5 minutes , then take out the pulverized material and pass through a grading sieve with an aperture of 1.0mm to obtain the initial mixture;

[0050] ②Put the primary mixture through a mechanical shearing ultrafine pulverizer for 3 minutes, then take out the pulverized material and pass it through a grading sieve with an aperture of 0.1 mm to obtain an ultrafine pulverized material;

[0051] ③Put the ultra-fine pulverized material into the conditioning machine...

Embodiment 2

[0055] (1) Weigh raw materials: fish meal 18.5kg, fish steak powder 17kg, corn gluten meal 6kg, soybean meal 28.3kg, rapeseed meal 5.2kg, high-gluten flour 19.7kg, soybean oil 2.2kg, calcium dihydrogen phosphate 1.6kg, bile chloride Base 0.2kg and premix 1.3kg.

[0056] (2) Preparation of feed:

[0057] ① After fully mixing fish meal, fish steak meal, corn gluten meal, soybean meal, rapeseed meal, high-gluten flour, calcium dihydrogen phosphate, choline chloride and premix, grind in a high-speed grinder at a speed of 1500rpm for 5 minutes , then take out the pulverized material and pass through a grading sieve with an aperture of 1.2mm to obtain the initial mixture;

[0058] ②Then the initial mixture is pulverized by a mechanical shearing ultrafine pulverizer for 3 minutes, and then the pulverized material is taken out and passed through a grading sieve with an aperture of 0.2 mm to obtain an ultrafine pulverized material;

[0059]③Put the ultra-fine pulverized material into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com