Building method of 3D printing weaving integrated forming building

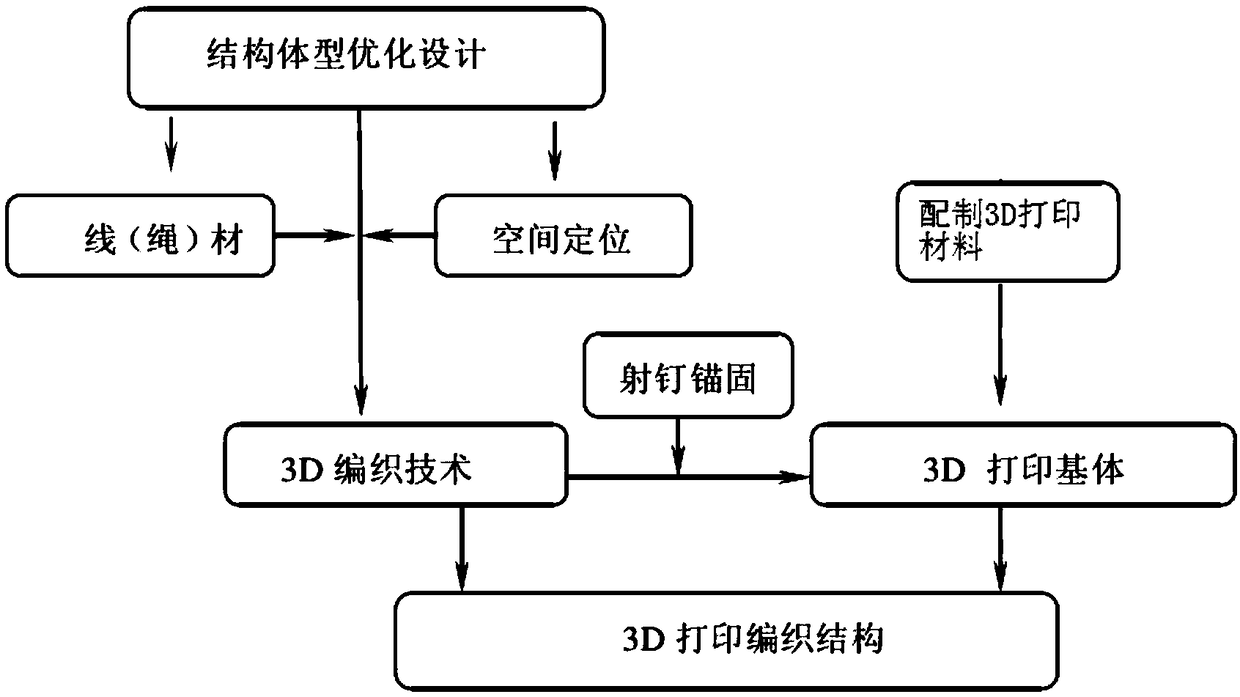

A 3D printing and construction method technology, applied in building construction, building material processing, construction, etc., to ensure the safety of structural stress, convenient construction, and solve the defects in strength and toughness performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

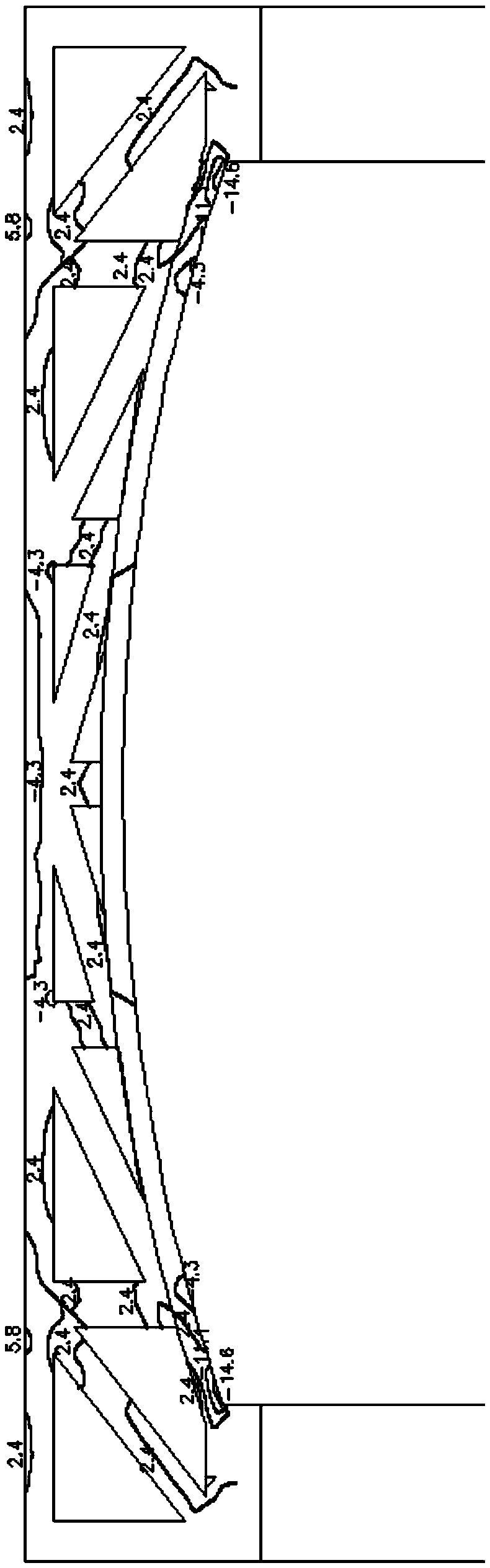

[0050] The design space model of the portal arch is used as a reference for the construction of the bridge structure.

[0051] 1. Determine the structural form and space shape according to the structural and functional requirements. Bridges usually choose beam or arch structures as their main stress components. 3D printing cement-based materials usually have high compressive strength and low tensile strength. Choosing arch shapes as the main stress components of bridge structures can make full use of the material's resistance compressive properties to avoid structural tensile fracture failure.

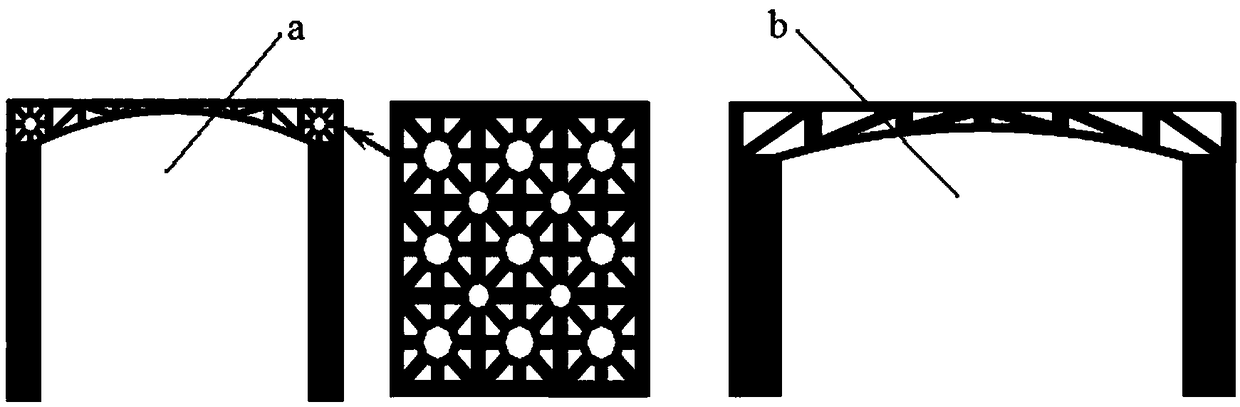

[0052] The spatial modeling and structural force of the arch structure are selected by structural topology optimization. In order to avoid missing the global optimal solution, two methods of truss discrete structure and continuum topology or a combination of the two can be used. The optimized structural form is regularized as figure 2 As shown, including scheme a and scheme b, the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com