Thermal dye sublimation transfer paper

A technology of thermal sublimation and transfer paper, applied in printing, copying/marking methods, etc., can solve the problems of single plate making, low production efficiency, poor precision, etc., and achieve the effect of avoiding many white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

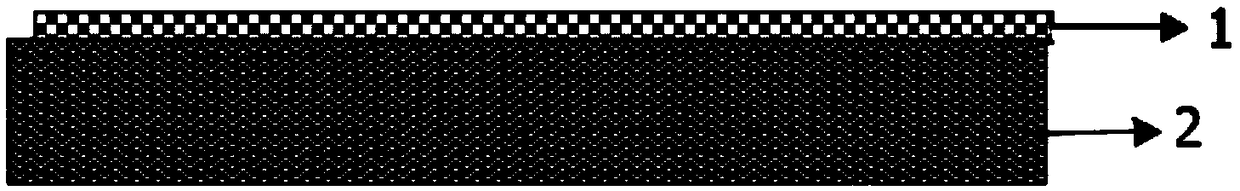

[0020] Such as figure 1 Shown, a kind of sublimation transfer paper, comprises base paper layer 2 and the coating layer 1 that is coated on base paper layer 2, and described coating layer 1 is made of the raw material of following mass parts: film-forming material 10-80 parts , 10-40 parts of adsorption material, 3-10 parts of adhesive, 1-10 parts of barrier agent and 0.1-2 parts of auxiliary agent. The adhesives are resins such as polyvinyl alcohol, coated starch latex, and styrene-butadiene latex mentioned in the prior art, and the auxiliary agents are materials such as defoamers, wetting agents, and lubricants mentioned in conventional technologies.

[0021] The film-forming material is used to receive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com