Composite crystal modifier for preparing alpha-type high-strength gypsum

A technology of high-strength gypsum and crystallizer, applied in the fields of calcium/strontium/barium compounds, inorganic chemistry, calcium/strontium/barium sulfate, etc. The effect of high product strength and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

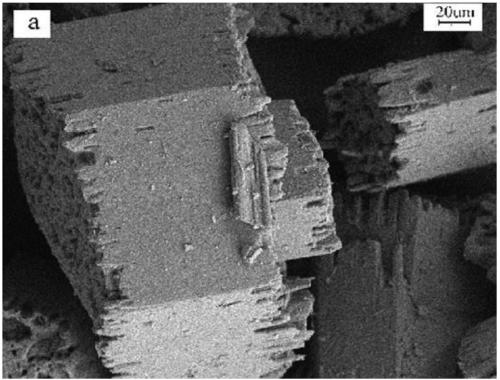

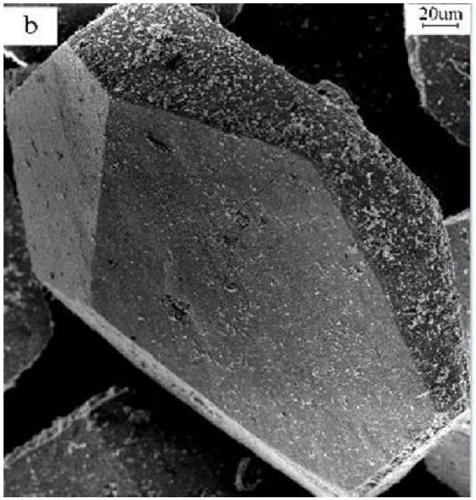

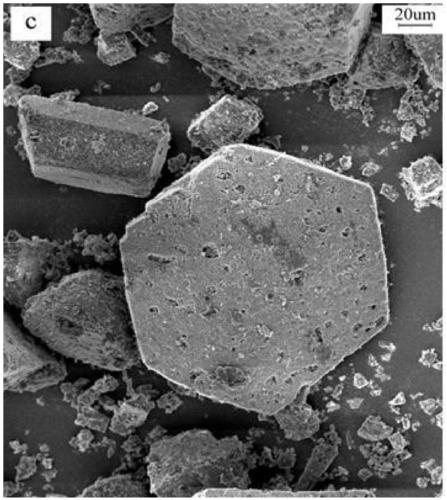

Image

Examples

Embodiment 1

[0032] In this example, α-type high-strength gypsum is prepared by using the high-pressure hydrothermal method combined with the crystal transformation agent described in the present invention. The main process steps are as follows:

[0033] 1) Preparation of slurry: stirring and mixing natural gypsum or industrial by-product gypsum whose main component is dihydrate gypsum with the crystal modifier of the present invention and a certain amount of water to form a gypsum suspension with a solid content of 10% to 50%;

[0034] 2) Crystallization of α-type hemihydrate gypsum: Add the above-mentioned gypsum suspension into the autoclave, heat and stir the gypsum suspension in the autoclave, and keep it warm at 110-140°C for 3h to 7h, after the crystallization is completed The slurry is kept warm and released for solid-liquid separation;

[0035] 3) Drying and grinding: After drying the separated solid at 100°C, it is modified by grinding (grinding into fine powder) to obtain α-type...

Embodiment 2

[0042] In this embodiment, the α-type high-strength gypsum is prepared by the normal pressure hydrothermal method combined with the crystal transformation agent described in the present invention, and the main process steps are as follows:

[0043] 1) Preparation of slurry: Stir and mix natural gypsum or industrial by-product gypsum whose main component is dihydrate gypsum, crystal modifier of the present invention, inorganic salt solution and a certain amount of water to form gypsum with a solid content of 10% to 50%. suspension;

[0044] 2) Crystallization of α-type hemihydrate gypsum: Add the above-mentioned gypsum suspension into an atmospheric pressure hydrothermal reaction kettle, heat and stir the gypsum suspension in the reaction kettle, and conduct a dynamic hydrothermal reaction at 85-100°C for 3-7 hours After the crystal transformation is completed, the slurry is kept warm and released, washed with boiling water and separated into solid and liquid;

[0045] 3) Dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com