Sialic acid and extraction method thereof

An extraction method and technology of sialic acid, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., to achieve the effect of reducing degradation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

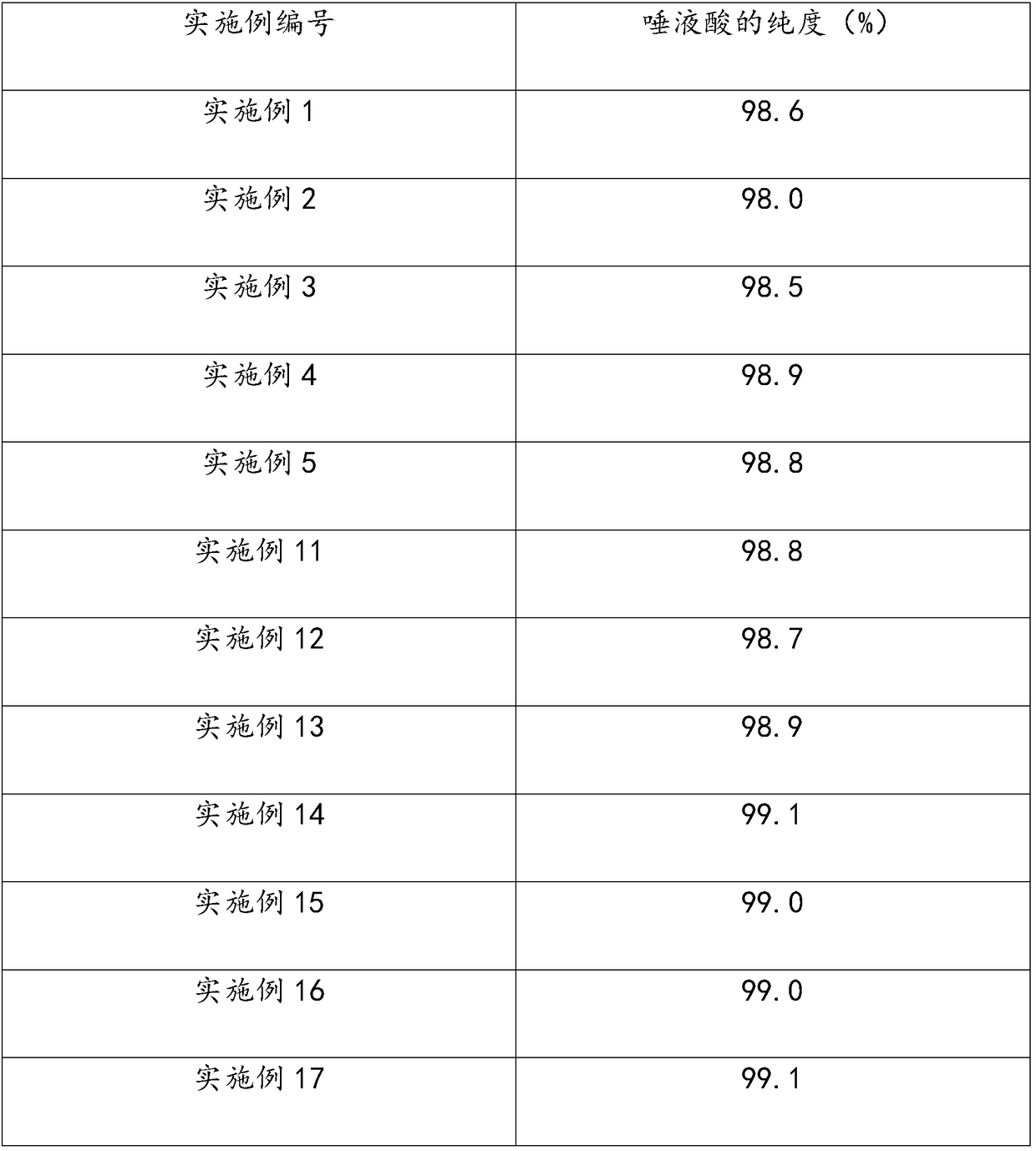

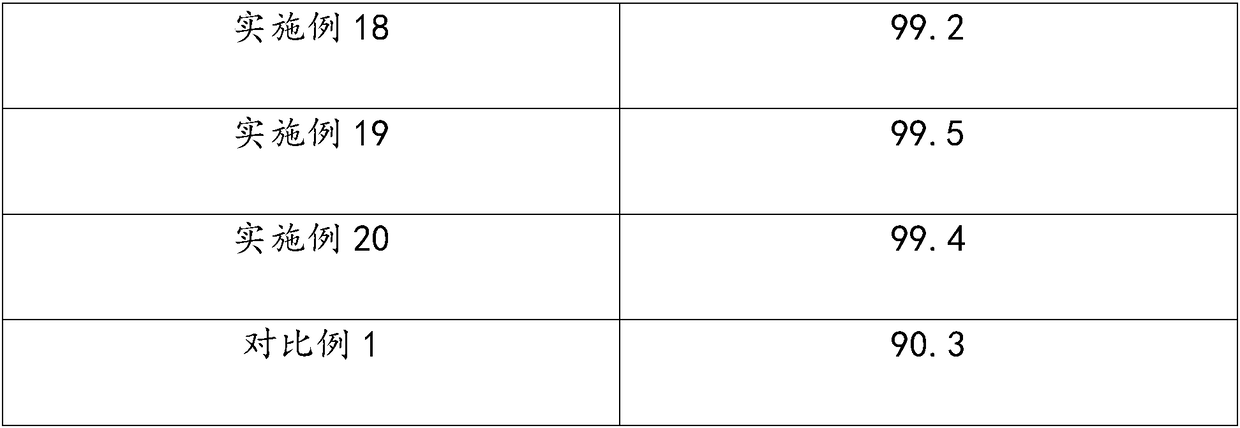

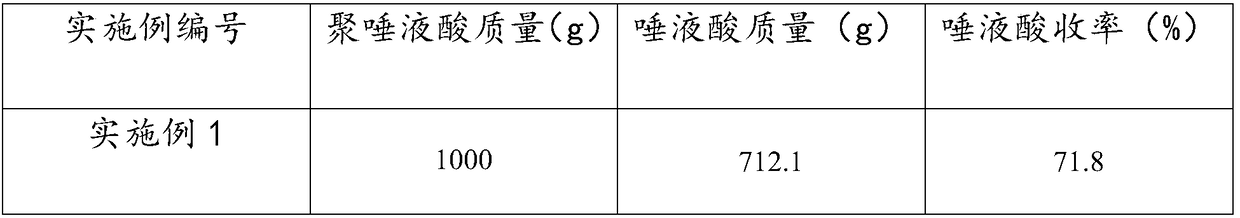

Examples

Embodiment 1

[0030] The 10g / L polysialic acid fermentation broth is filtered through a 100nm ceramic membrane to obtain the permeate, and the permeate is filtered through a 5KDa ultrafiltration membrane to remove small molecular compounds, so that the conductivity of the solution is less than 2000μS / cm, polysialic acid is in the ultra-strong The solid acid fixed bed was subjected to the hydrolysis reaction for 20 minutes, and the temperature of the hydrolysis reaction was 100°C.

[0031] After hydrolysis, use membrane filtration with a specification of 0.8KDa to obtain the sialic acid monomer solution and membrane filtration retentate, add 0.5% activated carbon to the sialic acid monomer solution and filter to obtain a decolorization solution, and put the membrane filtration retentate into a super strong solid acid for fixation The bed undergoes a secondary hydrolysis reaction. The decolorization solution was heated and concentrated under vacuum, then sulfuric acid was added until the pH o...

Embodiment 2

[0033] The 15g / L polysialic acid fermentation broth is filtered through a 150nm ceramic membrane to obtain a permeate, and the permeate is filtered through an 8KDa ultrafiltration membrane to remove small molecular compounds so that the conductivity of the solution is less than 2000μS / cm The solid acid fixed bed was subjected to the hydrolysis reaction for 25 minutes, and the temperature of the hydrolysis reaction was 90°C.

[0034] After hydrolysis, use membrane filtration with a specification of 0.9KDa to obtain the sialic acid monomer solution and membrane filtration retentate, add 1.5% activated carbon to the sialic acid monomer solution and filter to obtain a decolorization solution, and put the membrane filtration retentate into super strong solid acid for fixation The bed undergoes a secondary hydrolysis reaction. The decolorization solution was heated and concentrated in vacuum, then added glacial acetic acid until the pH of the solution was 2, acidified and crystalliz...

Embodiment 3

[0036]The 20g / L polysialic acid fermentation broth is filtered through a 200nm ceramic membrane to obtain the permeate, and the permeate is filtered through a 10KDa ultrafiltration membrane to remove small molecular compounds so that the conductivity of the solution is less than 2000μS / cm The solid acid fixed bed was subjected to the hydrolysis reaction for 30 minutes, and the temperature of the hydrolysis reaction was 85°C.

[0037] After hydrolysis, use a membrane filter with a specification of 1.0KDa to obtain the sialic acid monomer solution and membrane filtration retentate, add 2.5% activated carbon to the sialic acid monomer solution and filter to obtain a decolorization solution, and put the membrane filtration retentate into a super strong solid acid for fixation The bed undergoes a secondary hydrolysis reaction. The decolorization solution was heated and concentrated under vacuum, and then sulfuric acid was added until the pH of the solution was 1, acidified and crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com