Oil separator module with purifying and recycling functions

An oil purifier and functional technology, applied in the field of oil purifier modules, can solve problems such as difficult separation, difficult, unstable oil purifier purification, separation operation and system control, to reduce surface tension, reduce maintenance costs, and improve equipment Effects of operability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

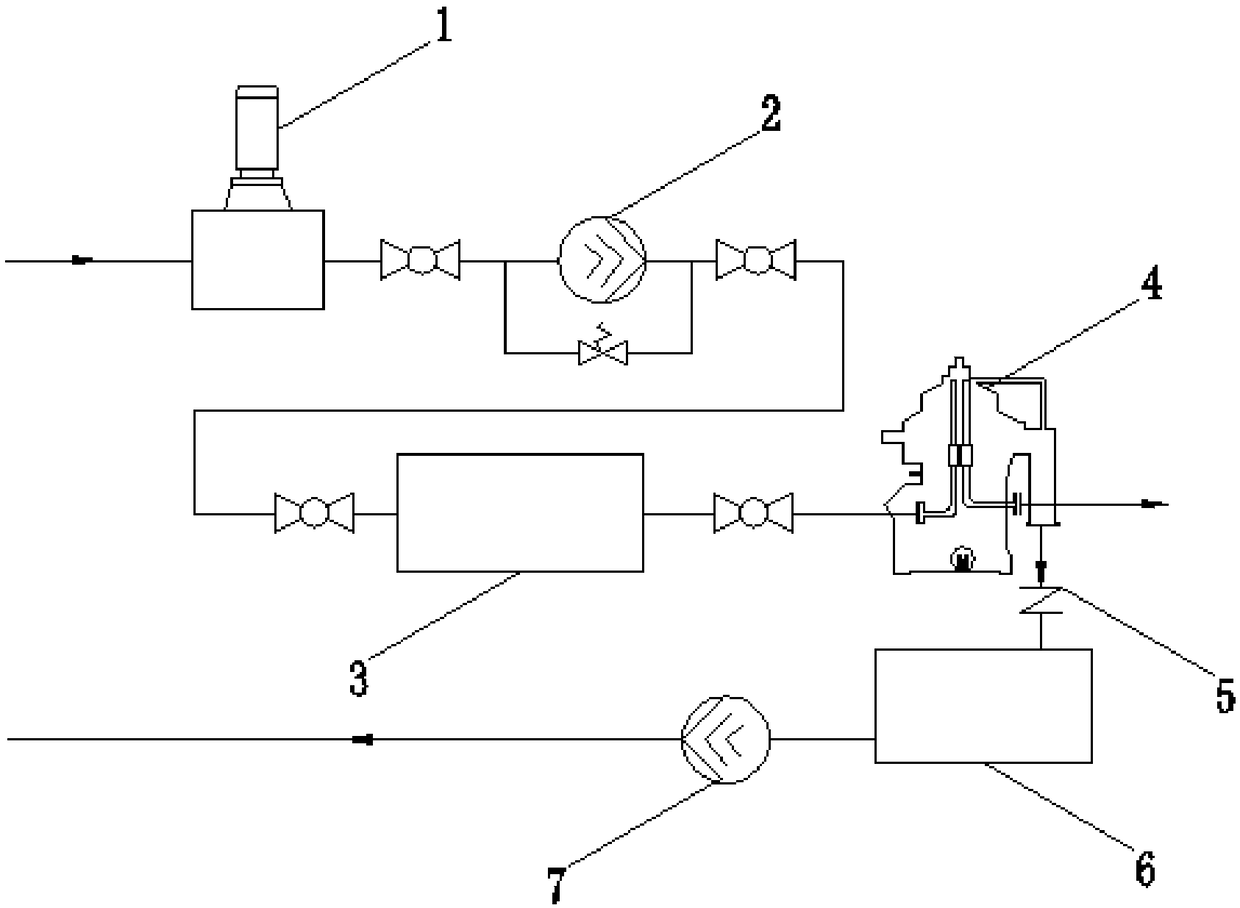

[0017] Such as figure 1 As shown, the oil purifier module with the function of purification and recovery includes an oil purifier module, a control electrical box and a module frame, and the oil purifier module includes a homogenizer 1, an oil supply pump 2, a heater 3, and an oil purifier 4 , Slag discharge valve 5, waste oil collection device 6, slag discharge pump 7.

[0018] The crude oil enters from the inlet of the homogenizer 1, the outlet of the homogenizer 1 is connected to the inlet of the oil supply pump 2 through a pipeline, the outlet of the oil supply pump 2 is connected to the inlet of the heater 3 through a pipeline, and the outlet of the heater 3 is connected to the oil separator through a pipeline 4, the oil purifier 4 is provided with a net oil outlet and a slag discharge port, and the net oil is discharged from the net oil outlet of the oil purifier 4, and the slag discharge port of the oil purifier 4 is connected to the inlet of the waste oil collection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com