Continuous leaching system for anode powder of waste lithium batteries and leaching technology

A technology for waste lithium battery and positive electrode is applied in the field of continuous leaching system and leaching process of waste lithium battery positive electrode powder. The effect of excessive, increased production efficiency, and reduced equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

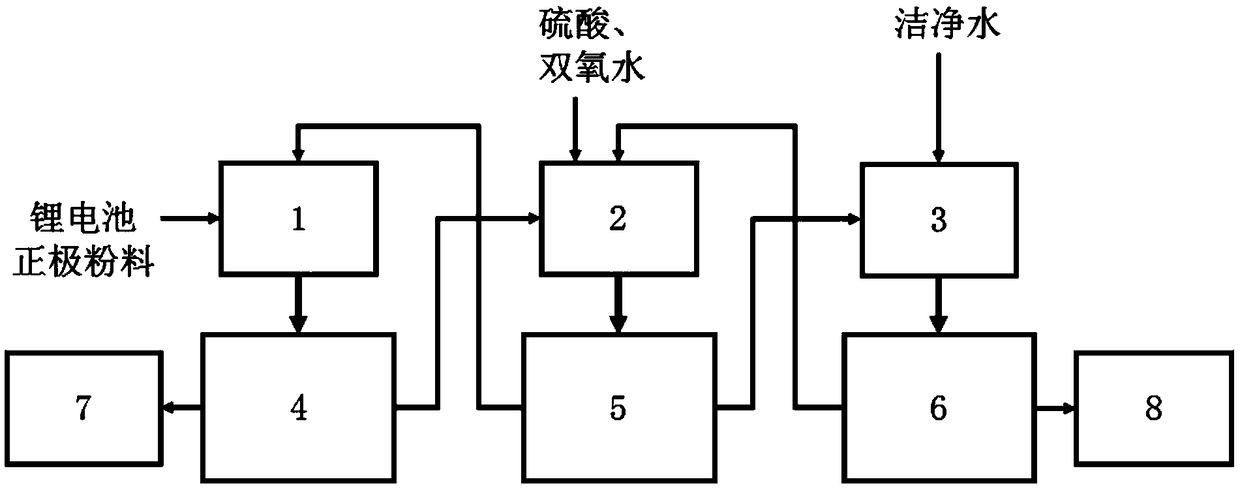

[0025] A kind of waste lithium battery positive electrode powder continuous leaching process that the present invention proposes, comprises the following steps:

[0026] S1, the clean water with 80L h -1 The flow of enters in the mixing tank 3;

[0027] S2. When the clean water starts to flow into the first reaction kettle 1, the heat-treated lithium iron phosphate battery positive electrode powder is charged at 10kg h -1 The speed is transmitted into the first reactor 1, wherein: the first reactor 1 is kept stirring continuously, the temperature is maintained at 85°C, and the residence time of the material is 80-150min;

[0028] S3. Transport the reaction slurry in the first reaction kettle 1 to the first continuous solid-liquid separator 4 through the first pipeline, and transport the pickling solution separated by the first continuous solid-liquid separator 4 through the fourth pipeline To the pickling solution storage tank 7, the solid obtained from the separation is tra...

Embodiment 2

[0035] A kind of waste lithium battery positive electrode powder continuous leaching process that the present invention proposes, comprises the following steps:

[0036] S1. Put the clean water in L·h -1 The flow of enters in the mixing tank 3;

[0037] S2. When the clean water starts to flow into the first reaction kettle 1, heat-treated 622 ternary battery positive electrode powder at 5 kg h -1 The speed is transmitted into the first reactor 1, wherein: the first reactor 1 is kept stirring continuously, the temperature is maintained at 85°C, and the residence time of the material is 80-150min;

[0038] S3. Transport the reaction slurry in the first reaction kettle 1 to the first continuous solid-liquid separator 4 through the first pipeline, and transport the pickling solution separated by the first continuous solid-liquid separator 4 through the fourth pipeline To the pickling solution storage tank 7, the solid obtained from the separation is transported to the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com