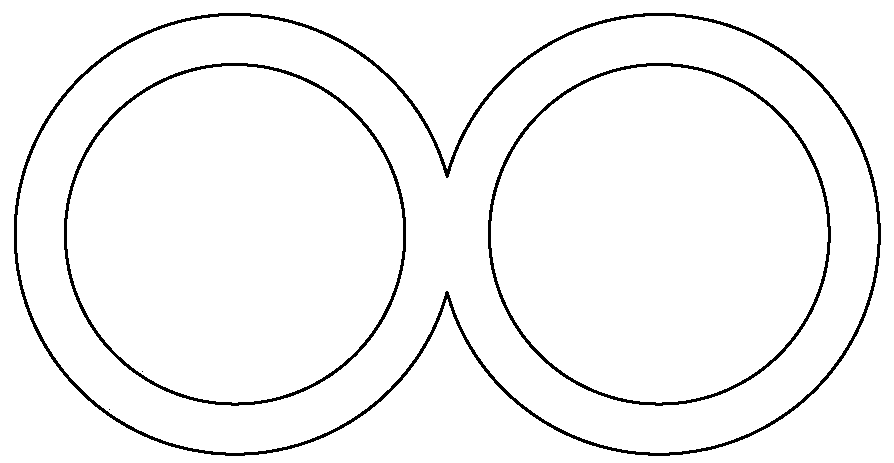

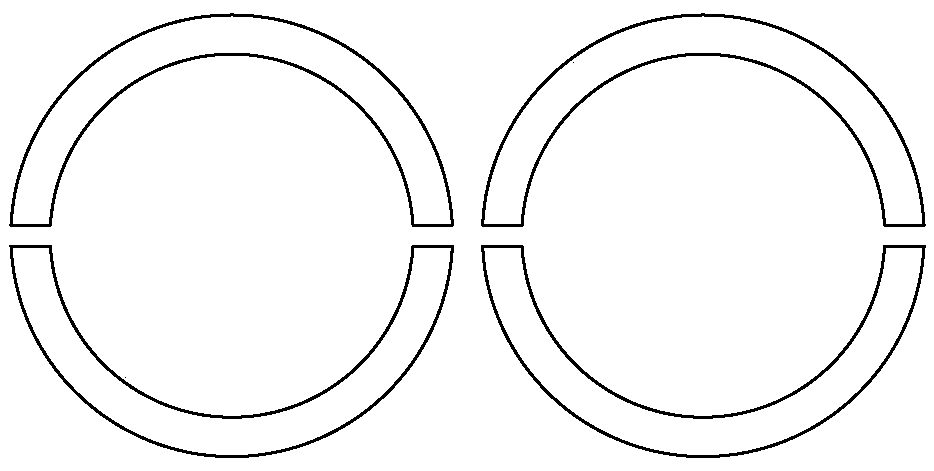

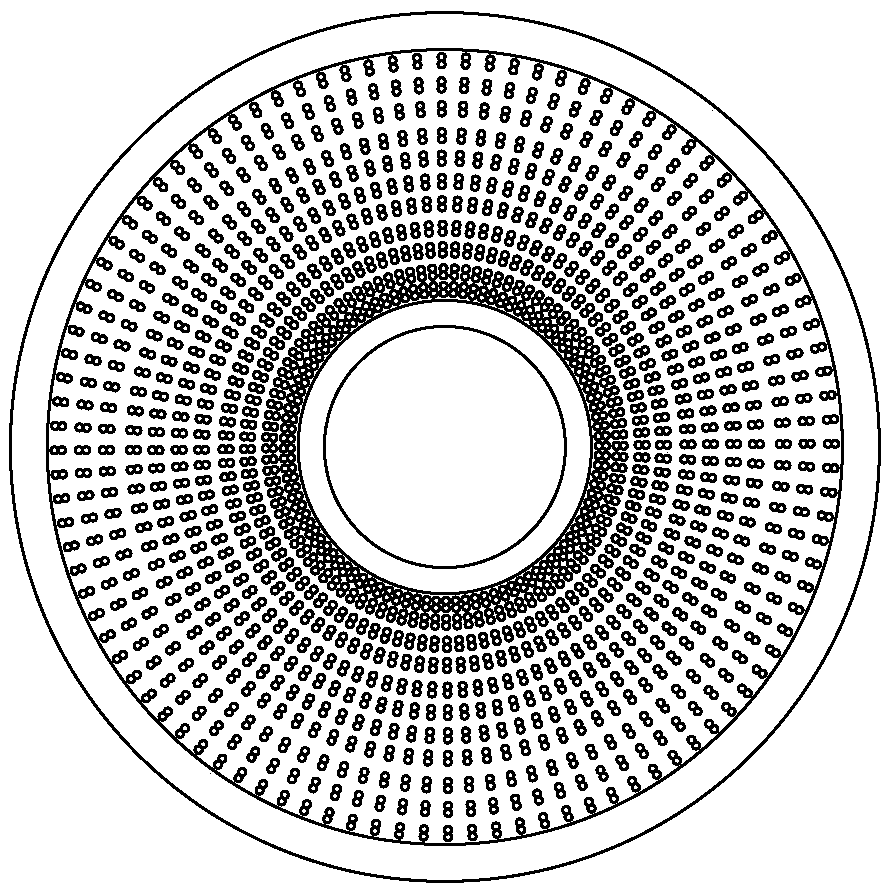

Method for spinning 8-shaped hollow staple fiber through regenerated polyester

A regenerated polyester, figure-8 technology, applied in the directions of melt spinning, fiber processing, hollow filament manufacturing, etc., to achieve the effects of improved fiber profile, high hollowness, and improved moisture absorption and air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for spinning figure-eight hollow staple fibers with recycled polyester material according to the present invention and the spinneret used therein are realized through the following steps: select recycled polyester material with an intrinsic viscosity of 0.58dl / g as raw material, send Put it into a vacuum drum dryer for drying, the drying temperature is 155°C, and the drying time is about 8 hours, so that the moisture content of the dried spinning raw material is less than 100PPM; the dried spinning raw material is fed into the melt spinning equipment for melt spinning , the molten spinning raw material is extruded into the spinning box through a screw extruder, and is sprayed out from the spinneret holes of the 8-shaped hollow spinneret to form nascent fibers; after that, the nascent fibers are cooled by a ring blowing device, and then passed through Winding, clustering, drafting, crimping, oiling, relaxing heat setting, cutting, and packaging to produce 8-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com