Hydraulic system with redundancy protection function

A redundant protection and hydraulic system technology, applied in the field of hydraulic systems, can solve problems such as low control accuracy, high hydraulic system failure rate, and poor safety control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

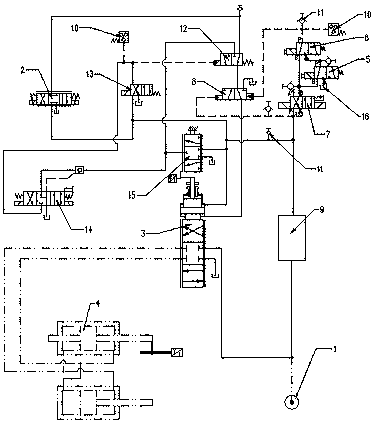

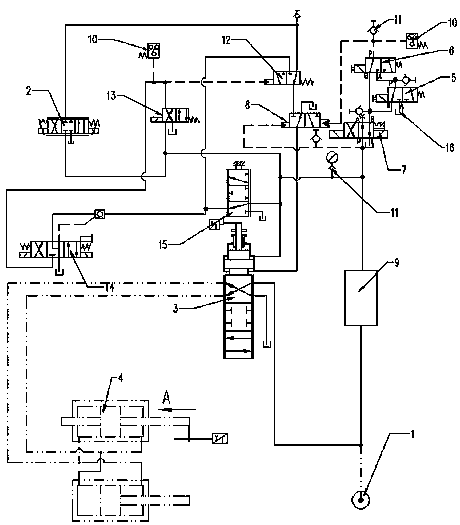

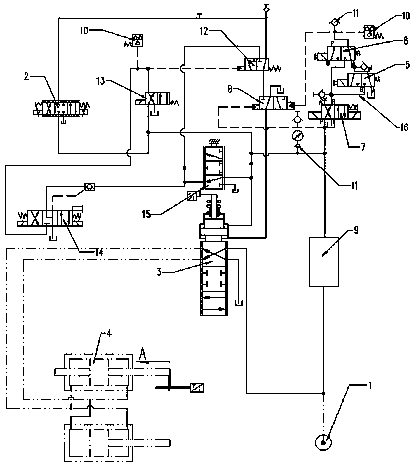

[0032] This embodiment, as a preferred embodiment of the present invention, discloses a hydraulic system for use in redundant protection functions, the specific structure is as follows figure 1 As shown, it includes hydraulic oil source 1, servo proportional valve 2, main pressure distribution valve 3 and guide vane servomotor 4. The main pressure distribution valve 3 is a three-position four-way reversing valve, and the main pressure distribution valve is also set There is a control piston, and a control chamber is provided on both sides of the control piston, wherein the area of the upper control chamber is smaller than the area of the lower control chamber, and the upper control chamber is directly connected with the hydraulic oil source 1 through the hydraulic oil filter 9, thereby forming a constant pressure control chamber; the lower control chamber is connected to the outlet end of the servo proportional valve through the differential pressure hydraulic control rever...

Embodiment 2

[0034]This embodiment, as the best embodiment of the present invention, discloses a hydraulic system with redundant protection function, the specific structure is as follows figure 1 As shown, it includes hydraulic oil source 1, servo proportional valve 2, main pressure distribution valve 3 and guide vane servomotor 4. The main pressure distribution valve 3 is a three-position four-way reversing valve, and the main pressure distribution valve is also set There is a control piston, and a control chamber is provided on both sides of the control piston, wherein the area of the upper control chamber is smaller than the area of the lower control chamber, and the upper control chamber is directly connected with the hydraulic oil source 1 through the hydraulic oil filter 9, thereby forming a constant pressure control chamber; the lower control chamber is connected to the outlet end of the servo proportional valve 2 through the differential pressure hydraulic control reversing valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com