Reconstruction method and structure for reconstructing wet-type cooling tower into dry-type cooling tower in power plant

A dry cooling tower, wet cooling technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as large air resistance, poor economy, and inconsistent service life of unit equipment , to achieve the effect of reducing air resistance, low cost of civil construction, and increasing effective height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

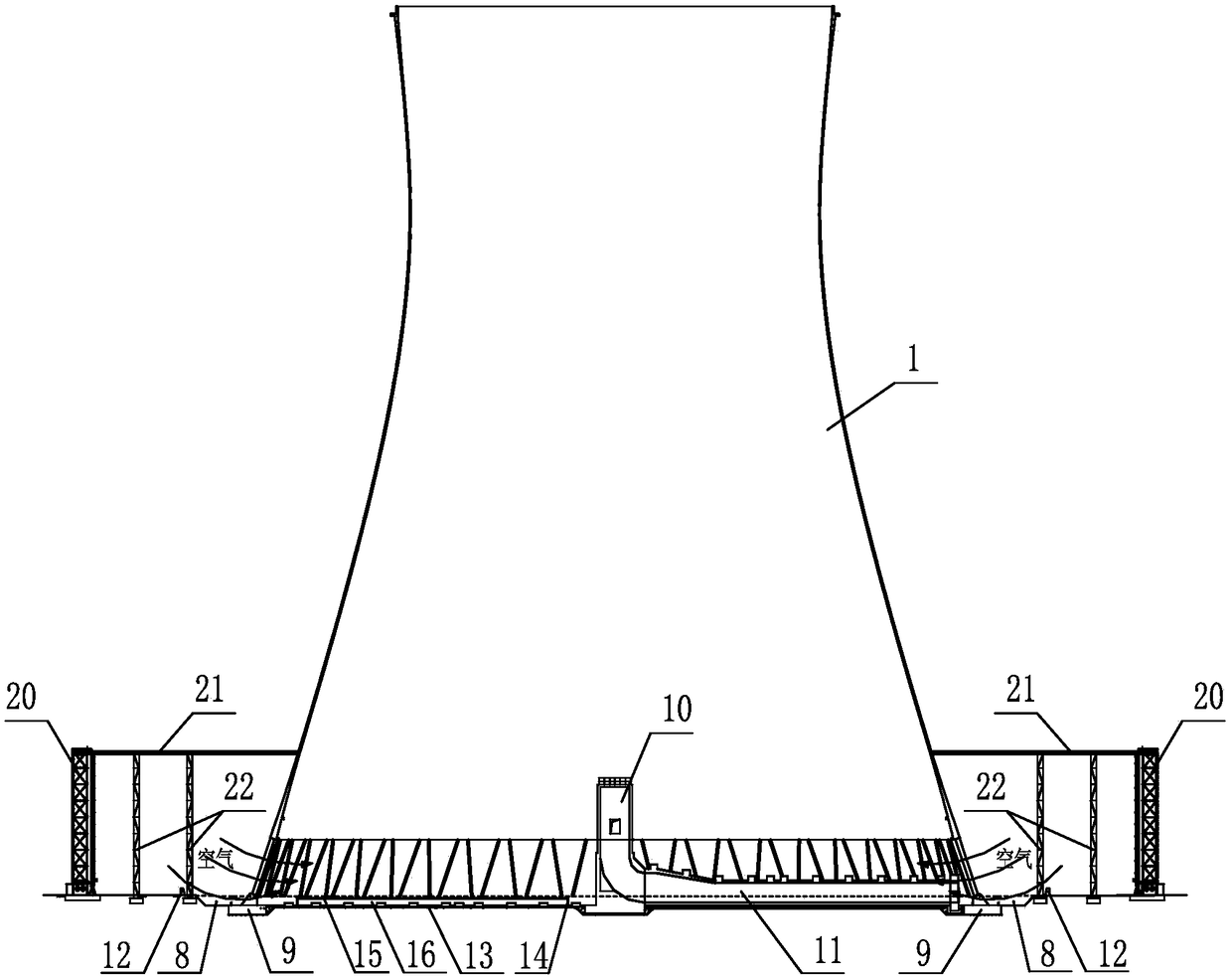

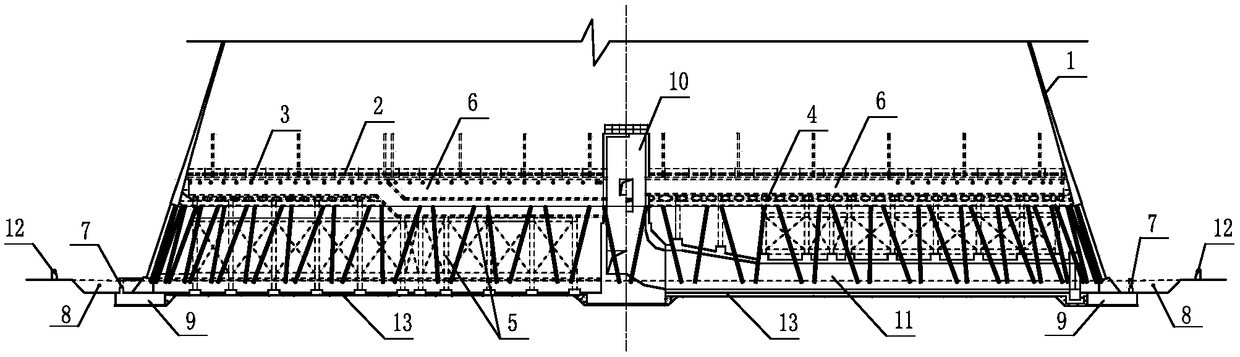

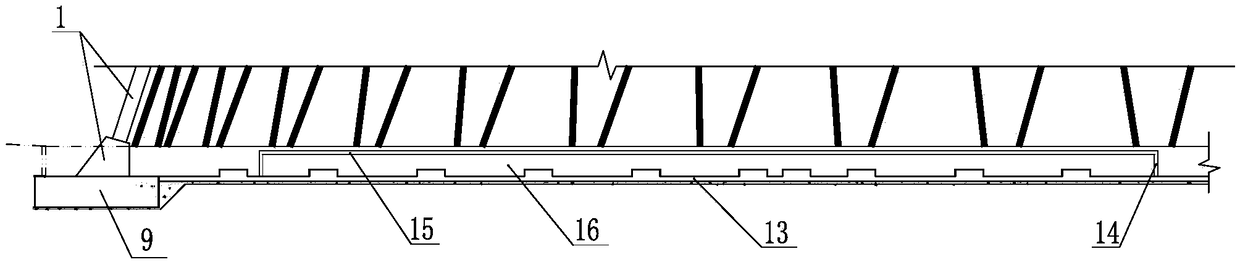

[0030] see Figure 1-4 , the invention provides a method for transforming a wet cooling tower into a dry cooling tower in a power plant, comprising the following steps:

[0031] Keep the cooling tower body 1 of the existing natural ventilation wet cooling tower; remove the water eliminator 2, water distribution piping system and nozzle 3, water spray filler and bracket 4, and frame beams and columns of the existing natural ventilation wet cooling tower etc.; remove the pool wall 7 of the sump pool at the bottom of the existing naturally ventilated wet cooling tower; excavate the surrounding soil 8 to the top surface elevation of the ring base 9 outside the pool wall of the existing naturally ventilated wet cooling tower sump; The heat exchanger 20 is arranged in a circular or non-circular plane, and is vertically arranged on the outer circumference of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com