Static high-pressure experiment data acquisition system and method based on LabVIEW

A technology for data acquisition systems and high-voltage experiments, which is applied in general control systems, control/regulation systems, and program control in sequence/logic controllers. There are problems such as data synchronization acquisition function, etc., to achieve effective CPU utilization, improve data analysis efficiency, and shorten the program development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

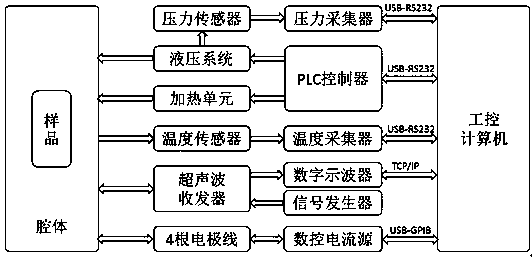

[0067] Embodiment 1: see Figure 1 to Figure 2 , a static high pressure experimental data acquisition system based on LabVIEW, comprising a sound velocity measuring device, the sound velocity measuring device comprising a six-sided press, an ultrasonic transceiver, a digital oscilloscope and a computer;

[0068] The six-sided top press includes a cavity for installing samples, 6 top hammers, a hydraulic system driving the top hammer movement, a heating unit and a PLC controller, and the hydraulic system and the heating unit are all connected with the PLC control connected to the device, and its work is controlled by a PLC controller, and the PLC controller is connected to a computer;

[0069] The ultrasonic transceiver is connected to a computer via a digital oscilloscope to transmit ultrasonic signals to the sample, and the received echo signal is displayed on the digital oscilloscope and then sent to the computer to calculate the sound velocity value;

[0070] It also inclu...

Embodiment 2

[0105] Example 2: see Figure 1 to Figure 6 , except the following content, all the other are identical with embodiment 1.

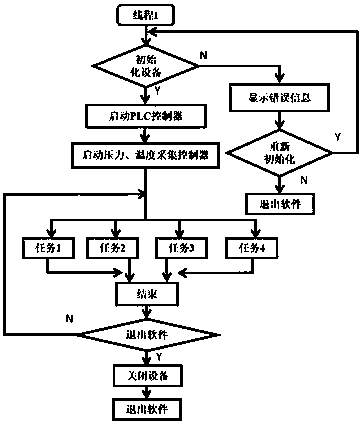

[0106] The computer mainly has 6 work tasks:

[0107] (1) Obtain the pressure and temperature values in the pressure and temperature collector;

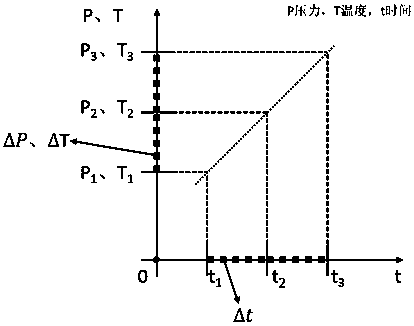

[0108] (2) The pressure and temperature values are used as feedback, and the segmented control algorithm written by the computer is used to accurately control the pressurization and heating of the six-sided top press;

[0109] (3) Control the numerical control current source to input current to the sample, measure the voltage, and display the current and voltage values in real time;

[0110] (4) Control the real-time acquisition of ultrasonic data by the digital oscilloscope, real-time display and storage;

[0111] (5) Receive the experimental conditions input by the user and convert them into control commands recognizable by the computer, which are used to control the digital oscilloscope and the nume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com