Method for stripping Ti3C2 nanosheet

A nanosheet and centrifugal treatment technology, applied in the field of two-dimensional materials, can solve problems such as increasing energy consumption, achieve the effects of controllable process, strong promotion and application value, and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1.1 will Ti 3 AlC 2 The powder is placed in a plastic beaker on a magnetic stirrer, press Ti 3 AlC 2 The mass ratio of powder to hydrofluoric acid is 1:10. Add hydrofluoric acid with a concentration of 40wt% to the same beaker, set the stirrer speed to 200r / min, and then start stirring for 3 hours.

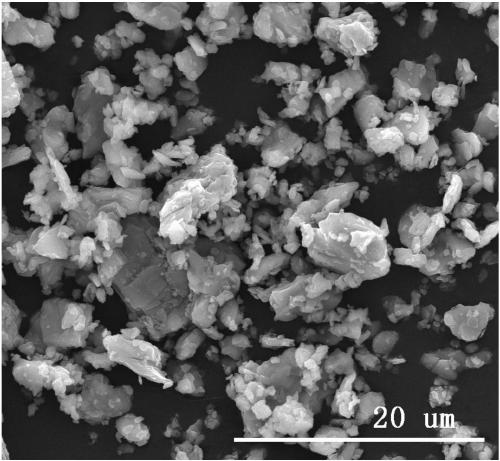

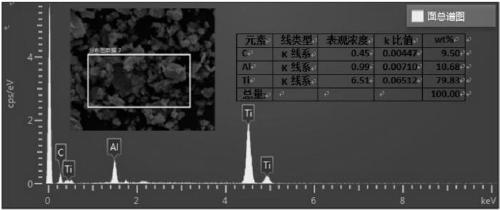

[0056] 1.2 Pour the etched solution into a centrifuge tube, then set the rotation speed to 4000r / min for centrifugation, take the precipitate, add deionized water to the precipitate for suction filtration and cleaning, repeat the cleaning 4 times, and then separate the solid phase The powder was heated at an ambient temperature of 100°C for 24 hours and dried continuously to obtain stacked lamellar Ti 3 C 2 Powder.

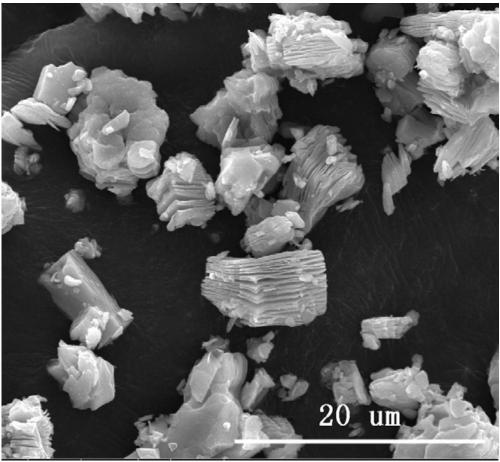

[0057] 1.3 will Ti 3 C 2 Put the powder into a glass beaker, then fill the mouth of the beaker with porous polyimide foam, and insert a funnel into the opening on the foam, and pour 20ml of liquid nitrogen into the funnel immediately after the beaker is ...

Embodiment 2

[0067] 2.1 will Ti 3 AlC 2 The powder is placed in a plastic beaker on a magnetic stirrer, press Ti 3 AlC 2 The mass ratio of powder to hydrofluoric acid is 1:10. Add hydrofluoric acid with a concentration of 40wt% to the same beaker, set the stirrer speed to 200r / min, and then start stirring for 3 hours.

[0068] 2.2 Pour the etched solution into a centrifuge tube, then set the rotation speed to 4000r / min for centrifugation, take the precipitate, add deionized water to the precipitate for suction filtration and cleaning, repeat the cleaning 4 times, and then separate the solid phase The powder was heated at an ambient temperature of 100°C for 24 hours and dried continuously to obtain stacked lamellar Ti 3 C 2 Powder.

[0069] 2.3 Will Ti 3 C 2 Put the powder into a glass beaker, then fill the mouth of the beaker with porous polyimide foam, and insert a funnel into the opening on the foam, and pour 20ml of liquid nitrogen into the funnel immediately after the beaker is ...

Embodiment 3

[0074] 3.1 Will Ti 3 AlC 2 The powder is placed in a plastic beaker on a magnetic stirrer, press Ti 3 AlC 2 The mass ratio of powder to hydrofluoric acid is 1:10. Add hydrofluoric acid with a concentration of 40wt% to the same beaker, set the stirrer speed to 200r / min, and then start stirring for 3 hours.

[0075] 3.2 Pour the etched solution into a centrifuge tube, then set the rotation speed to 4000r / min for centrifugation, take the precipitate, add deionized water to the precipitate for suction filtration and cleaning, repeat the cleaning 4 times, and then separate the solid phase The powder was heated at an ambient temperature of 100°C for 24 hours and dried continuously to obtain stacked lamellar Ti 3 C 2 Powder.

[0076] 3.3 Will Ti 3 C 2 Put the powder into a glass beaker, then fill the mouth of the beaker with porous polyimide foam, and insert a funnel into the opening on the foam, and pour 20ml of liquid nitrogen into the funnel immediately after the beaker is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com