Permeable concrete floor dyeing agent and preparation method thereof

A floor dyeing agent and concrete technology, applied in the field of building materials, can solve problems such as ability to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

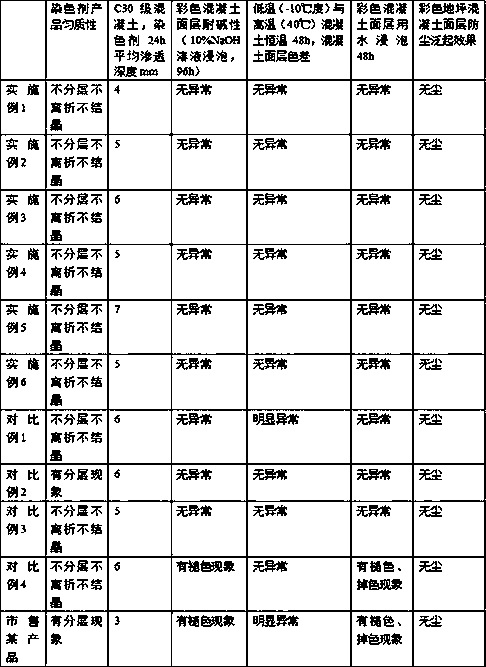

Examples

Embodiment Construction

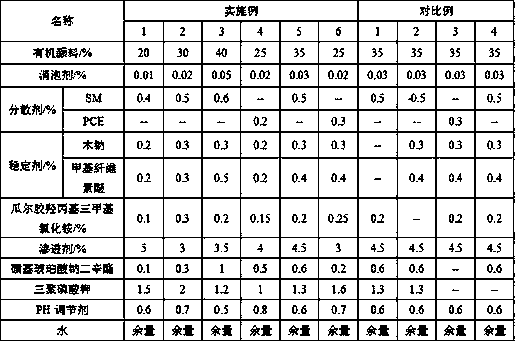

[0019] Below in conjunction with embodiment do specific explanation.

[0020] The used raw material of embodiment is as follows:

[0021] Azo pigment (red or yellow), powder, produced by Jiangsu Decai Pigment Chemical Co., Ltd.

[0022] Phthalocyanine (blue or green) pigment, powder, produced by Nantong Zhenxin Pigment Co., Ltd.;

[0023] Nigrosine pigment, powder, produced by Dezhou Hongqiao Dye Chemical Co., Ltd.;

[0024] Silicone defoamer, powder, produced by Changzhou Shunhua Chemical Co., Ltd.;

[0025] Polyether defoamer, liquid, content 96.5%, produced by Weifang Saiyang Industry and Trade Co., Ltd.;

[0026] Wood sodium, powder, produced by Jilin Chenming Paper Co., Ltd.;

[0027] MC methyl cellulose ether, powder, produced by Zhejiang Haishen New Material Co., Ltd.;

[0028] CMC cellulose ether, powder, produced by Hebei Renqiu Litian Chemical Co., Ltd.;

[0029] Guar gum hydroxypropyltrimethylammonium chloride, powder, produced by Shandong Baihong New Material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com