Two-position two-way normally closed type miniature high-flow fuel electromagnetic valve

A high-flow, solenoid valve technology, applied in the field of solenoid valves, can solve the problems of large volume, heavy mass, and high startup energy consumption of high-flow solenoid valves, and achieve the effects of light weight, low startup energy consumption, and large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

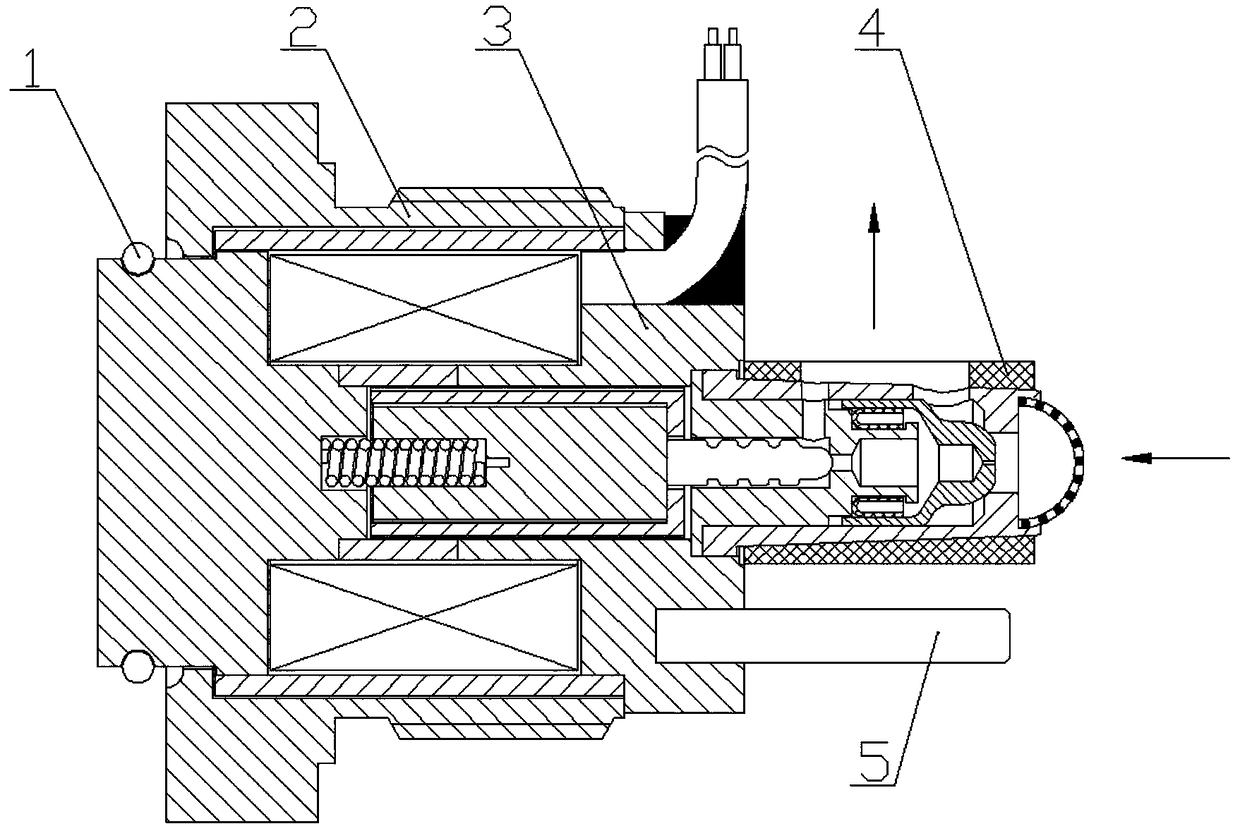

[0033] Embodiment of the present invention: a two-position two normally closed miniature high-flow fuel solenoid valve, as attached figure 1 As shown, it is mainly composed of steel wire retaining ring 1, installation shell 2, valve assembly 3, sealing bush 4, positioning pin 5, as attached figure 1 shown. When assembling, put the installation shell 2 on the outside of the valve assembly 3, buckle the steel wire retaining ring 1 into the valve assembly 3, install the sealing bush 4 on the valve assembly 3, and press the positioning pin 5 into the valve assembly. Assembly 3 holes.

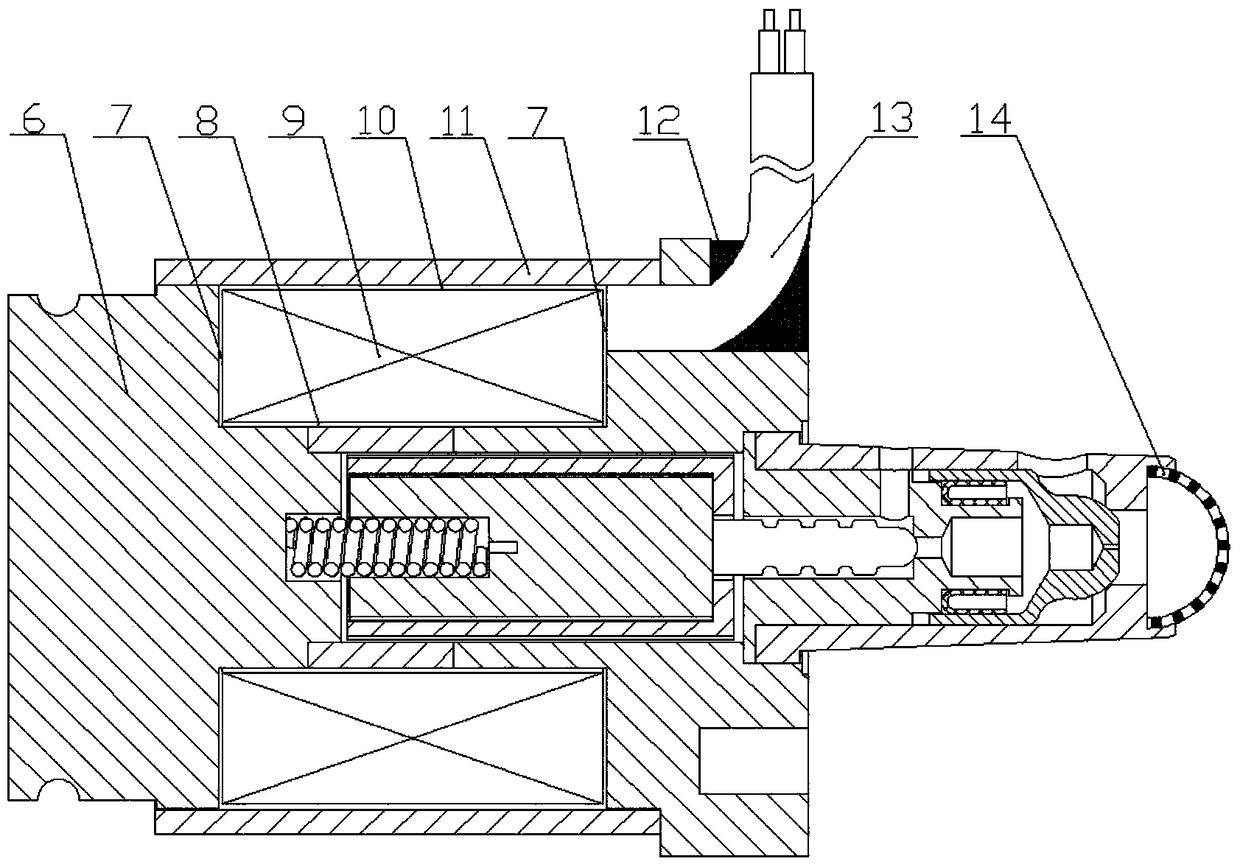

[0034] as attached figure 2 As shown, the valve assembly 3 is mainly composed of a coil frame assembly 6, an insulating gasket 7, polyimide 8, enamelled round copper wire 9, an alkali-free glass fiber tape 10, a coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com