Fresh milk and preparation technology thereof

A preparation process and fresh milk technology are applied in the field of long shelf-life full-fat pasteurized fresh milk and its preparation process, which can solve the problems of large loss of nutrients and high total residual amount of microorganisms, achieve small loss of nutrients and improve the flavor of fresh milk. , the effect of improving food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

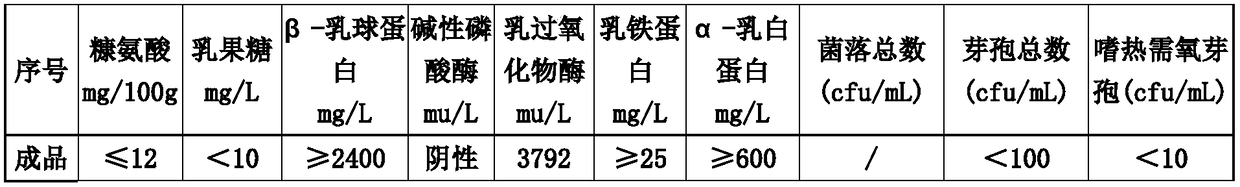

Embodiment 1

[0036] This embodiment provides a kind of fresh milk and its preparation process. The preparation process comprises the steps of:

[0037] 1) Fresh raw milk taken from healthy udders is used as raw milk, and the protein, fat, non-fat milk solids, density and acidity contained in it are tested. The acceptance criteria meet the national food safety standard of GB19301. Cold chain storage at ℃;

[0038] 2) Pass the cooled milk through a 100-120 mesh filter to remove dust and other impurities in the milk; finally, centrifuge the static milk at 4000rpm and 2°C to remove non-milk cells and other impurities, and collect the purified material;

[0039] 3) Under the pressure of 30bar, pass the purified material through a reverse osmosis membrane (RO membrane) with a pore size of <0.001μm for reverse osmosis membrane concentration, and collect the concentrated material;

[0040] 4) At 55°C, milk fat is separated from the concentrated material, skim milk and cream are collected separat...

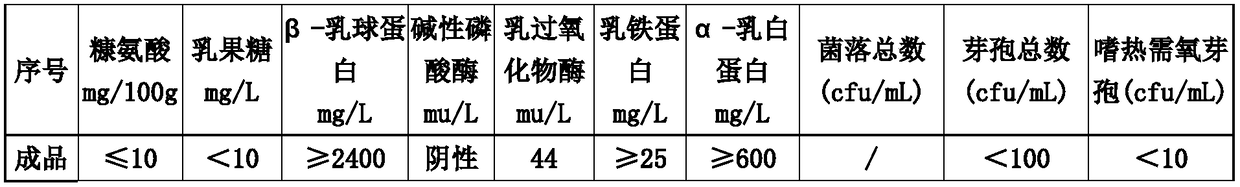

Embodiment 2

[0052] This embodiment provides a kind of fresh milk and its preparation process. The preparation process comprises the steps of:

[0053] 1) Fresh raw milk taken from healthy udders is used as raw milk, and the protein, fat, non-fat milk solids, density and acidity contained in it are tested. The acceptance criteria meet the national food safety standard of GB19301. Cold chain storage at ℃;

[0054] 2) Pass the cooled milk through a 100-120 mesh filter to remove dust and other impurities in the milk; finally, centrifuge the static milk at 5000rpm and 5°C to remove non-milk cells and other impurities, and collect the purified material;

[0055] 3) Under the pressure of 31bar, pass the purified material through a reverse osmosis membrane (RO membrane) with a pore size of <0.001μm for reverse osmosis membrane concentration, and collect the concentrated material;

[0056] 4) At 57°C, milk fat is separated from the concentrated material, skim milk and cream are collected separatel...

Embodiment 3

[0068] This embodiment provides a kind of fresh milk and its preparation process. The preparation process comprises the steps of:

[0069] 1) Fresh raw milk taken from healthy udders is used as raw milk, and the protein, fat, non-fat milk solids, density and acidity contained in it are tested. The acceptance criteria meet the national food safety standard of GB19301. Cold chain storage at ℃;

[0070] 2) Pass the cooled milk through a 100-120 mesh filter to remove dust and other impurities in the milk; finally, centrifuge the static milk at 5500rpm and 6°C to remove non-milk cells and other impurities, and collect the purified material;

[0071] 3) Under the pressure of 32bar, pass the purified material through a reverse osmosis membrane (RO membrane) with a pore size of <0.001μm for reverse osmosis membrane concentration, and collect the concentrated material;

[0072] 4) At 60°C, milk fat is separated from the concentrated material, skim milk and cream are collected separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com