Method for improving beef tenderness based on multiple times of fermentation

A multiple-fermentation and secondary-fermentation technology, which is applied in the fields of food processing and microbial fermentation, can solve the problem of hardening of beef meat, achieve the effect of short time consumption, simple operation, and improvement of beef tenderness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

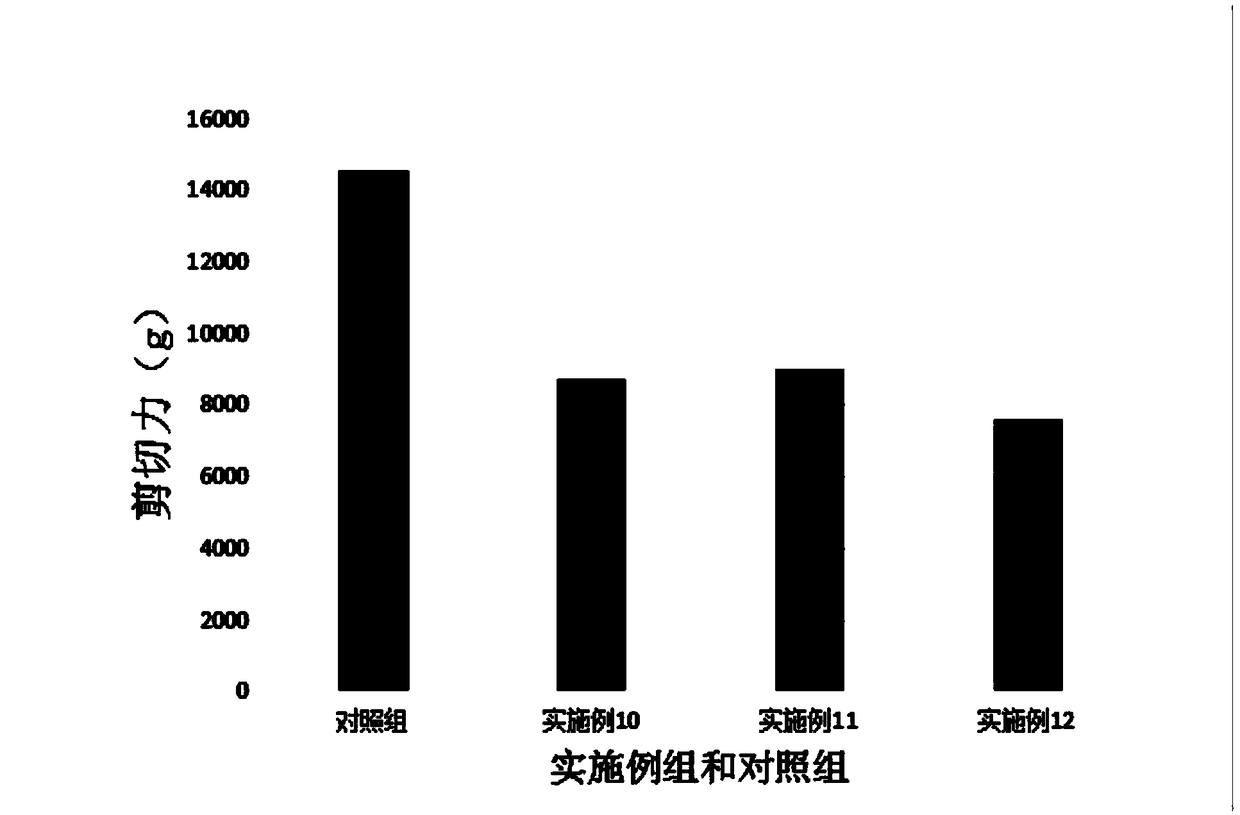

[0081] Embodiment 7: The ingredients are, by weight, 40 parts of table salt, 20 parts of dark soy sauce, 1 part of cooking wine, 3 parts of black pepper, 5 parts of ginger, and 10 parts of white sugar; the concentration of kiwi fruit juice in the tenderizer is 3%. The tenderizer was injected into the beef treated in Example 6, the injection amount was 7% of the weight of the beef, and the prepared ingredients were added, and the tumbling treatment was carried out for 10 minutes under the condition of vacuum degree of 4.6kpa.

Embodiment 8

[0082] Embodiment 8: The ingredients are, by weight, 42 parts of table salt, 15 parts of dark soy sauce, 1.5 parts of cooking wine, 2 parts of black pepper, 7 parts of ginger, and 5 parts of white sugar; the concentration of kiwi fruit juice in the tenderizer is 3.5%. The tenderizer was injected into the beef treated in Example 4, the injection amount was 5% of the weight of the beef, and the prepared ingredients were added, and the tumbling treatment was carried out for 13 minutes under the condition of a vacuum degree of 5 kpa.

Embodiment 9

[0083] Embodiment 9: The ingredients are, by weight, 45 parts of table salt, 18 parts of dark soy sauce, 2 parts of cooking wine, 2.5 parts of black pepper, 10 parts of ginger, and 7 parts of white sugar; the concentration of kiwi fruit juice in the tenderizer is 3.3%. The tenderizer was injected into the processed beef in Example 5, the injection amount was 6% of the weight of the beef, and the prepared ingredients were added, and the vacuum degree was 4kpa, and the tumbling process was carried out for 15 minutes.

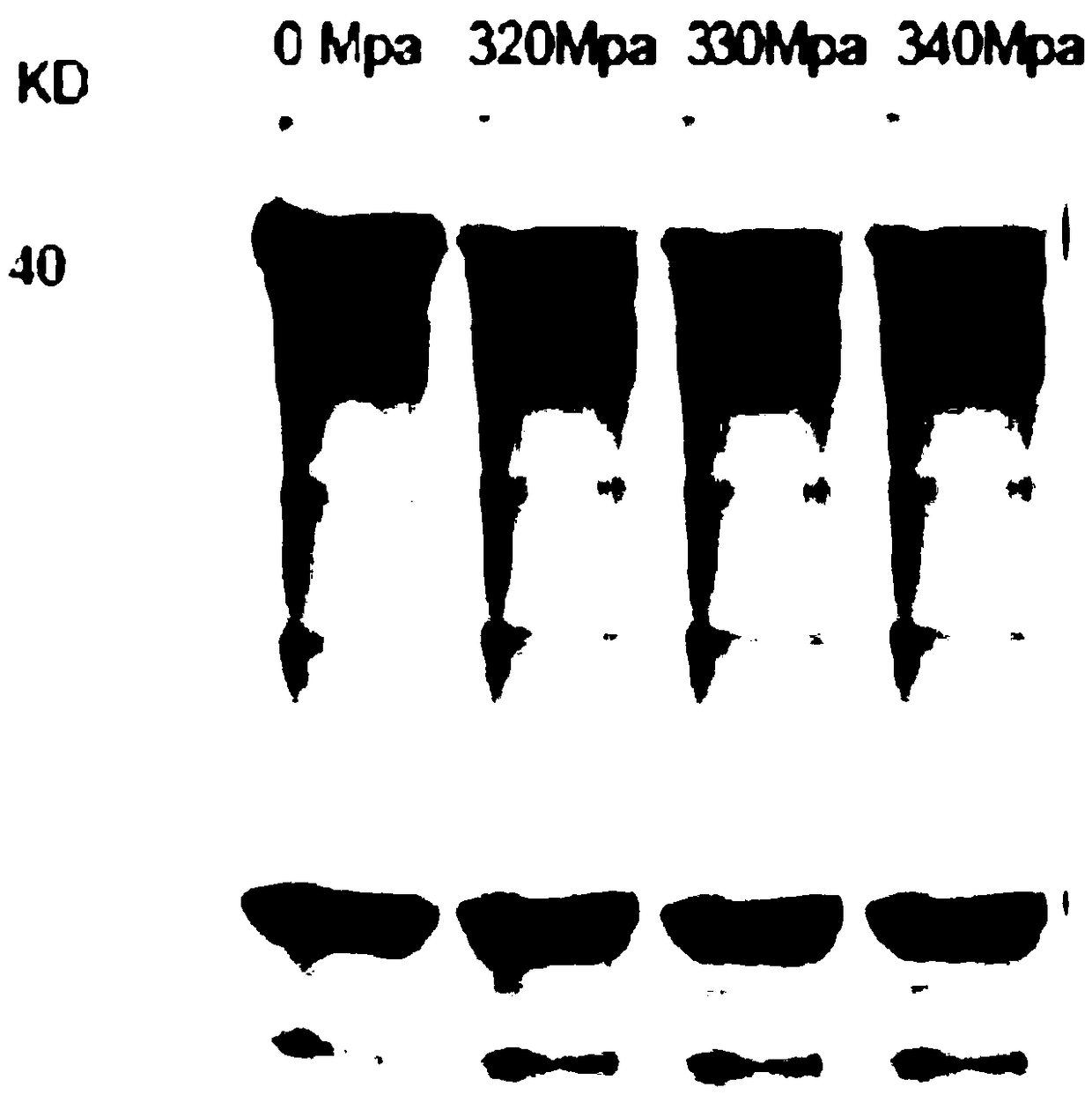

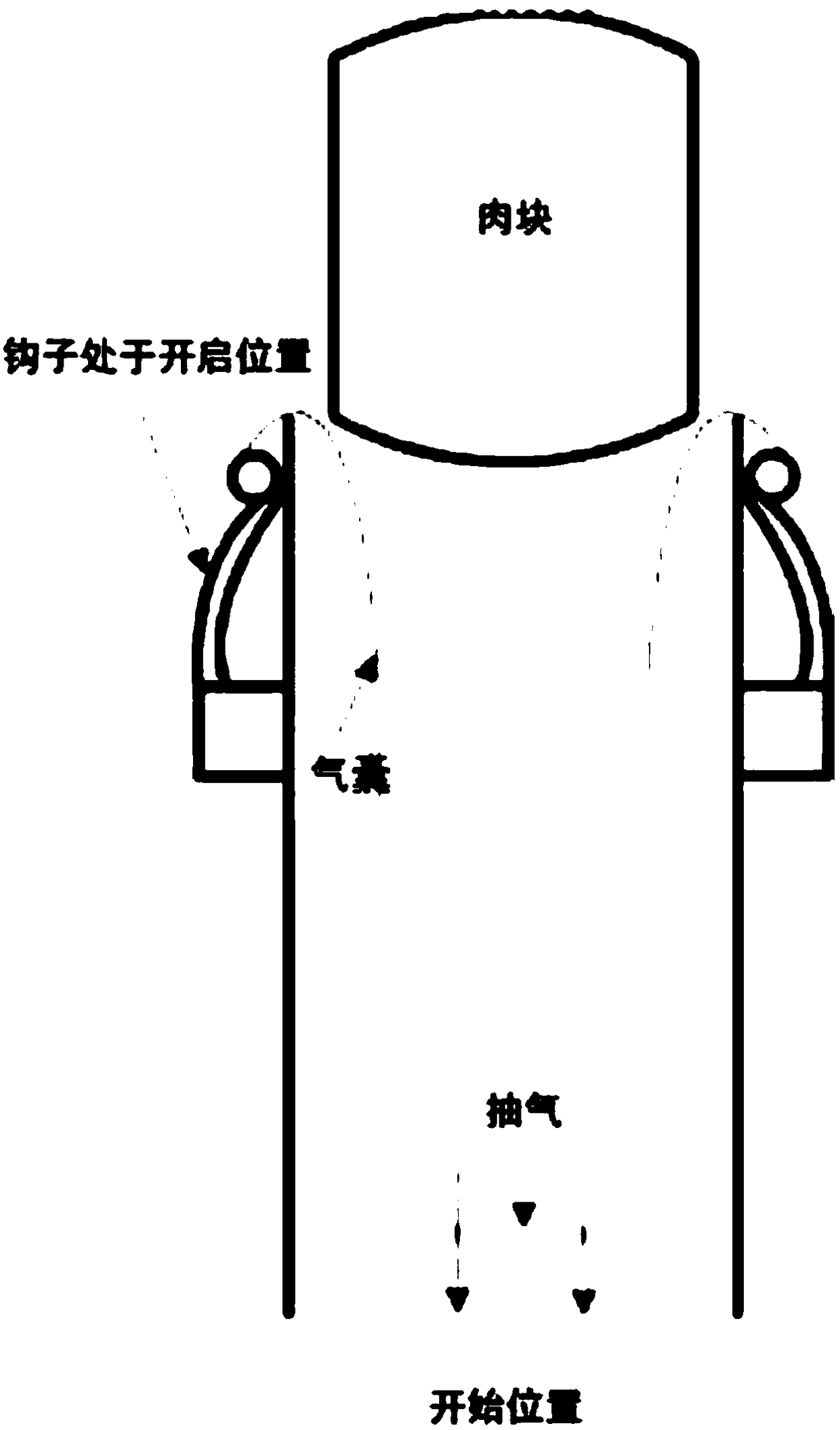

[0084] Ⅲ. The Streptococcus thermophilus in S4 of the present invention is inoculated into the beef after S3 treatment, and fermented once after non-vacuum tumbling for 5 minutes. The environmental conditions for fermentation are 20-22° C. of temperature, 83-85% relative humidity, and 19 hours of fermentation time. ~ 20 hours; followed by secondary fermentation at a temperature of 30-32° C. and an ambient humidity of 50-65%, for 4-5 hours. Wherein, the first ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com