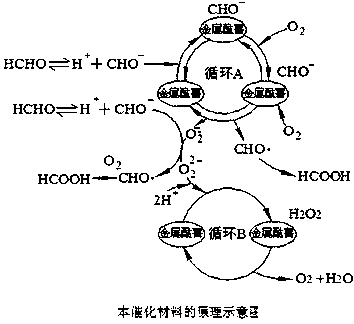

Preparation method for non-photocatalytic material for purifying polluting gas

A photocatalytic material and gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, gas treatment, etc., can solve the problems of secondary pollution, difficult regeneration, low photocatalytic efficiency, etc., and achieve high added value and plasticity. Strong, easy-to-regenerate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A non-photocatalytic material for purifying polluting gases, the preparation technical scheme of which is as follows:

[0020] According to the number of parts by mass, 1 part of modified metal phthalocyanine, 6 parts of ethanol and 19 parts of water were added to the reactor, and stirred for 35 minutes to dissolve them all; then 13 parts of activated carbon were added to the reactor, Immerse under water for 13 hours; filter after impregnation, dry the activated carbon in an oven at 110°C for 260 minutes, then transfer to a tube furnace, and roast at 450°C for 140 minutes in an air atmosphere; A non-photocatalytic material for purifying polluting gas is obtained.

[0021] The activated carbon is mesoporous activated carbon.

[0022] Described modified metal phthalocyanine is prepared according to the following scheme:

[0023] According to the number of parts by mass, 33 parts of 4-(3,5-dicarboxy) phenoxyphthalonitrile and 38 parts of fuming sulfuric acid were added t...

Embodiment 2

[0027] A non-photocatalytic material for purifying polluting gases, the preparation technical scheme of which is as follows:

[0028] According to the number of parts by mass, 0.5 parts of modified metal phthalocyanine, 4 parts of ethanol and 16 parts of water were added to the reactor, and stirred for 30 minutes to dissolve them all; Immerse under water for 10 hours; filter after impregnation, dry the activated carbon in an oven at 100°C for 240 minutes, then transfer to a tube furnace, and roast at 400°C for 120 minutes in an air atmosphere; A non-photocatalytic material for purifying polluting gas is obtained.

[0029] The activated carbon is mesoporous activated carbon.

[0030] Described modified metal phthalocyanine is prepared according to the following scheme:

[0031]According to the number of parts by mass, 30 parts of 4-(3,5-dicarboxy)phenoxyphthalonitrile and 35 parts of fuming sulfuric acid were added to the reaction kettle, the temperature was controlled at 120...

Embodiment 3

[0035] A non-photocatalytic material for purifying polluting gases, the preparation technical scheme of which is as follows:

[0036] According to the number of parts by mass, 1.5 parts of modified metal phthalocyanines, 8 parts of ethanol and 24 parts of water were added to the reactor, and stirred for 40 minutes to completely dissolve; then 15 parts of activated carbon were added to the reactor, Immerse under water for 15 hours; filter after impregnation, dry the activated carbon in an oven at 120°C for 300 minutes, then transfer to a tube furnace, and roast at 500°C for 150 minutes in an air atmosphere; A non-photocatalytic material for purifying polluting gas is obtained.

[0037] The activated carbon is mesoporous activated carbon.

[0038] Described modified metal phthalocyanine is prepared according to the following scheme:

[0039] According to the number of parts by mass, 35 parts of 4-(3,5-dicarboxy)phenoxyphthalonitrile and 40 parts of fuming sulfuric acid were ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com