Solid waste comprehensive utilization method in multi-metal sulfide mineral mining-smelting overall process

A solid waste and sulfide ore technology, applied in the direction of solid waste removal, etc., can solve the problems of fine-grained copper tailings that cannot be properly disposed of, surrounding environmental hazards, and occupation of farmland and cultivated land, etc., to achieve easy large-scale commercial production, The method is simple and the self-test method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

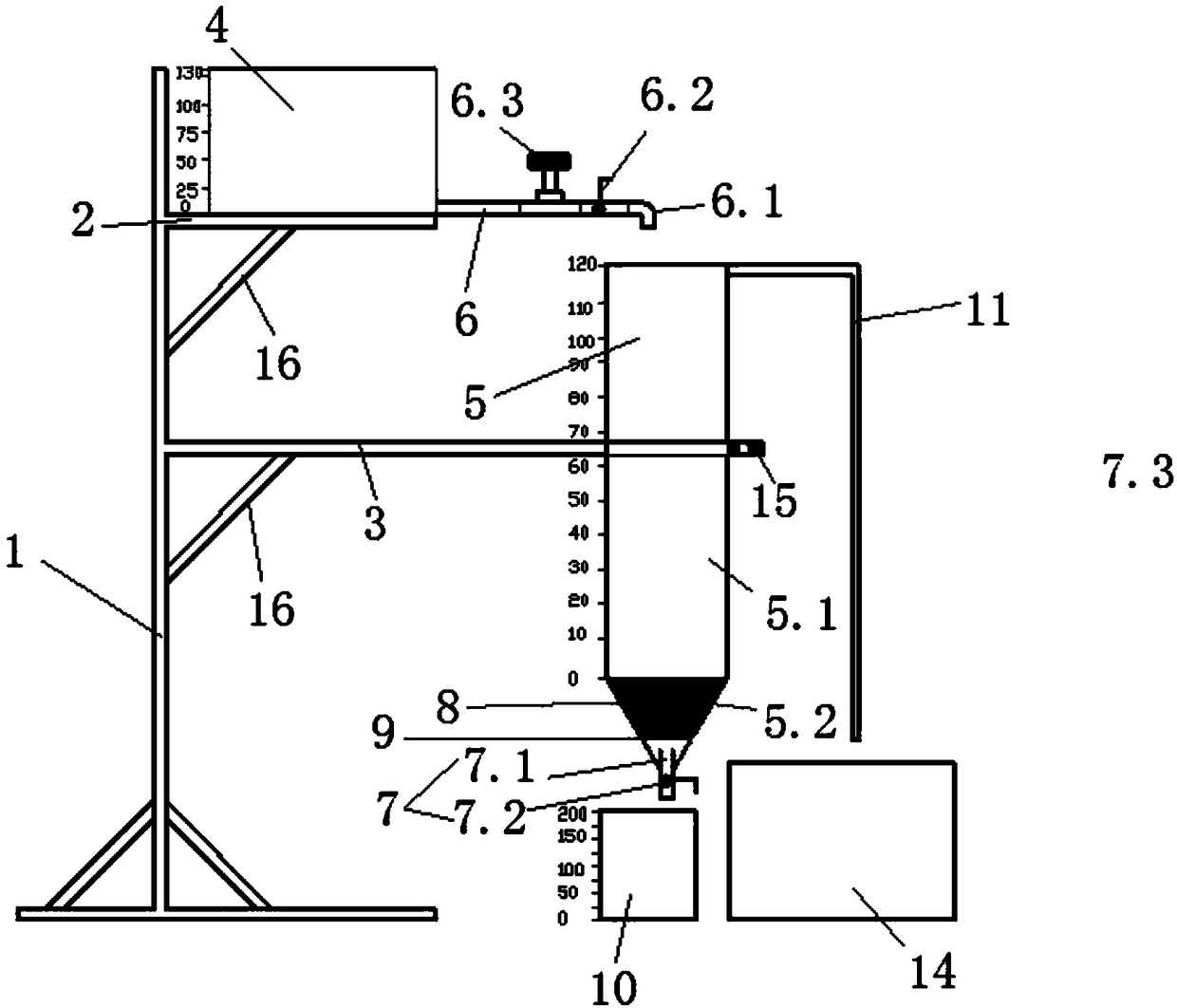

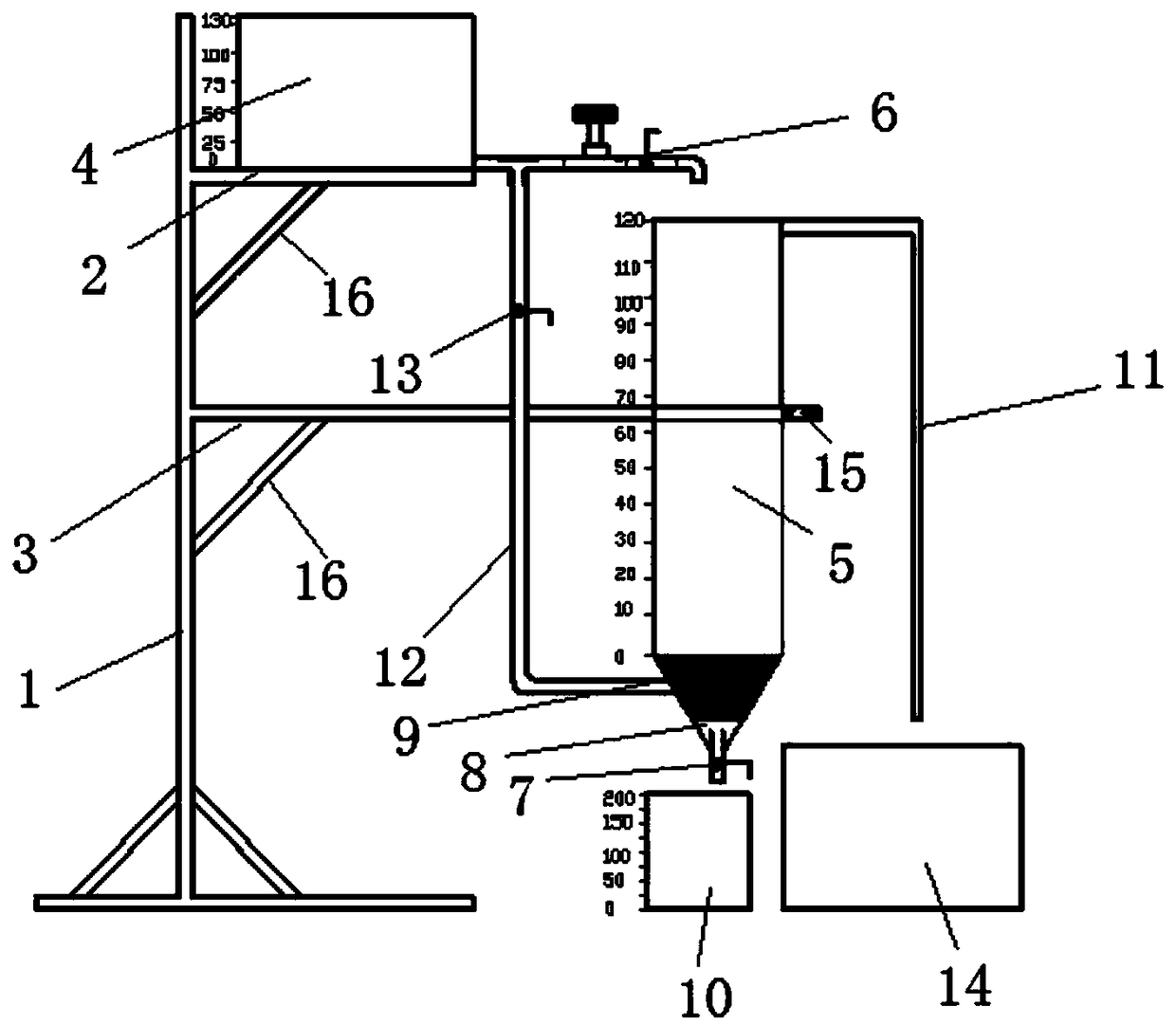

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

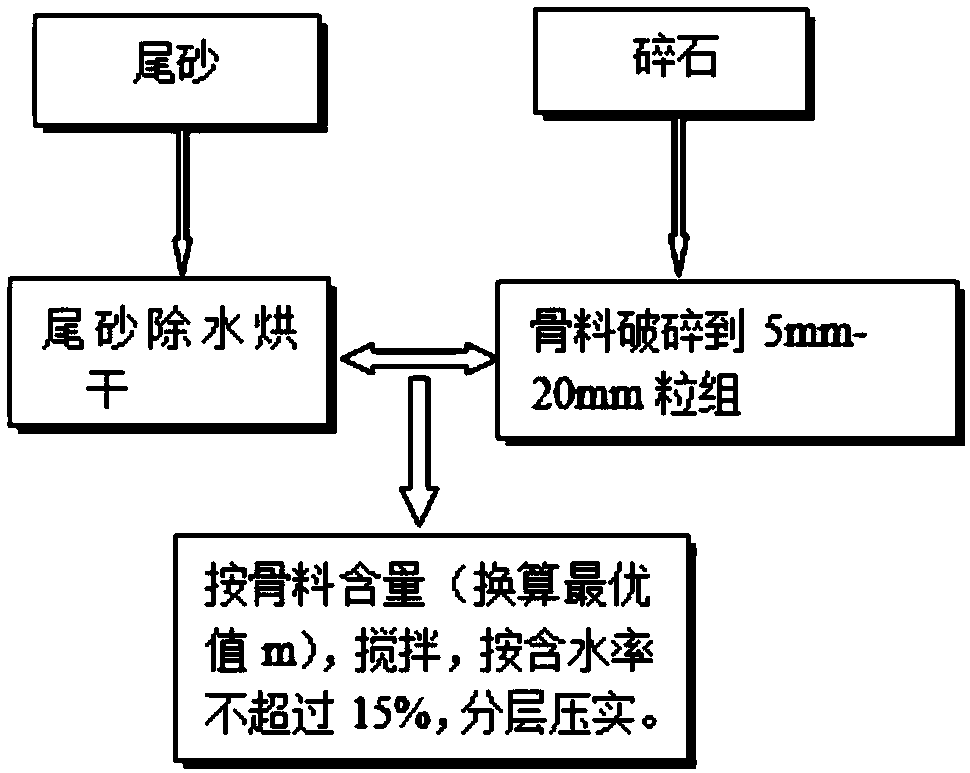

[0025] It can be seen from the flow chart of a method for comprehensive utilization of solid waste in the whole process of polymetallic sulfide ore mining-smelting shown in the accompanying drawings that the technical scheme of the present invention is as follows,

[0026] Firstly, identify the components, and use the horizontal oscillation method of leaching experiment to analyze the heavy metal content in the leaching solution of mined gravel and smelting tailings respectively; the heavy metal content is required not to exceed the national standard, usually the heavy metal content in the mined gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com