Laminated glass with asymmetric thickness and production method thereof

A laminated glass, asymmetric technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems that cannot meet the molding requirements, affect the bending performance of double-sheet glass, etc., achieve high yield, no bright spot and light The effect of distortion and curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described below in conjunction with the accompanying drawings.

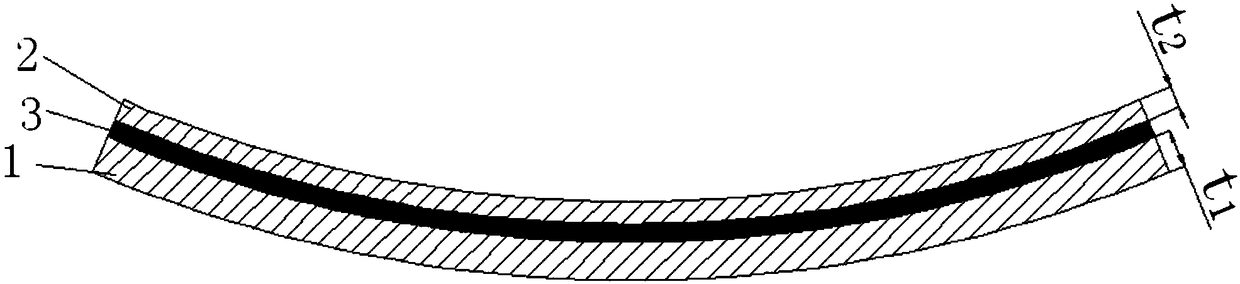

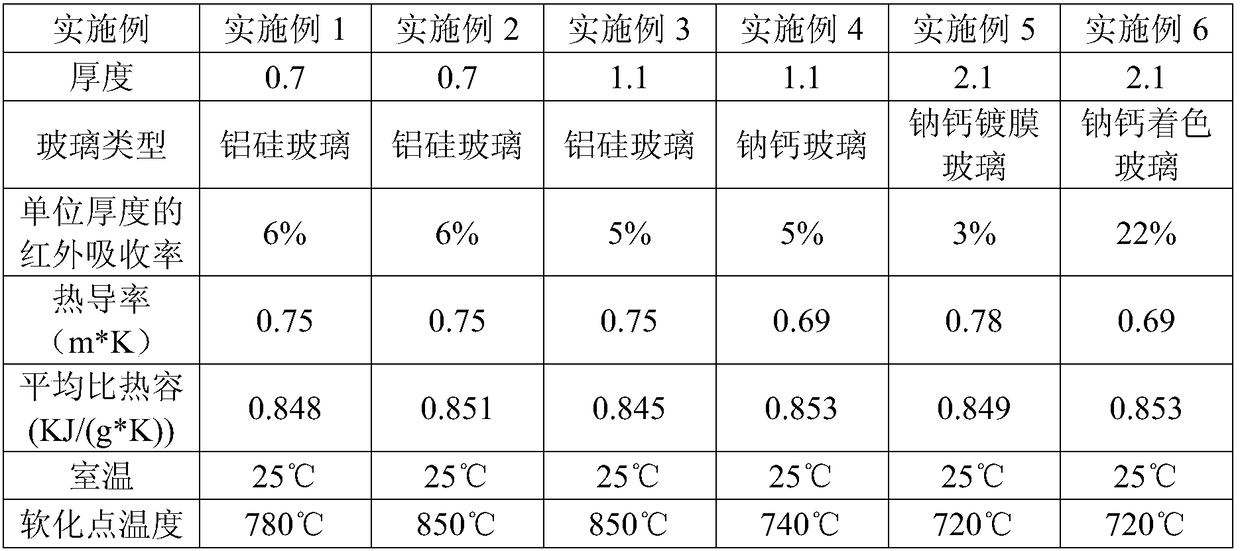

[0031] Such as figure 1 As shown, a laminated glass with an asymmetric thickness according to the present invention includes a thick glass plate 1 and a thin glass plate 2 with different thicknesses bent and formed, and is arranged between the thick glass plate 1 and the thin glass plate 2 The polymer interlayer 3 between, the thick glass plate 1 is preferably soda-lime glass, the thin glass plate 2 is preferably aluminosilicate glass or soda-lime glass, it is characterized in that: the softening point temperature of the thick glass plate 1 Tf 1 and the softening point temperature Tf of the thin glass plate 2 2 Satisfy the following relationship:

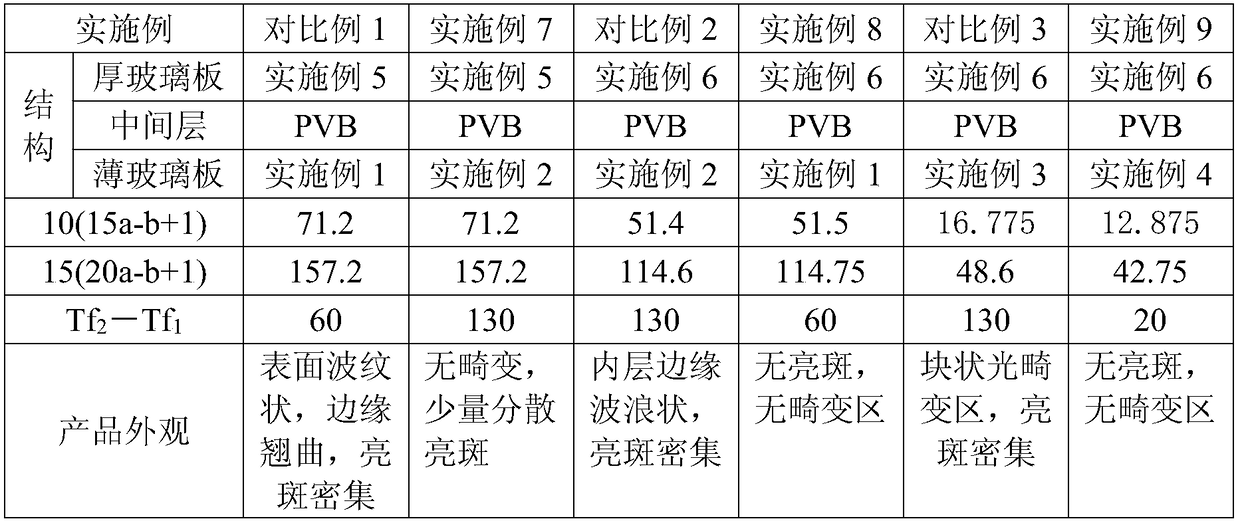

[0032] 10(15a-b+1)≤Tf 2 -Tf 1 ≤15(20a-b+1);

[0033] in, t 1 is the thickness of thick glass plate 1, t 2 is the thickness of the thin glass plate 2, R 1 is the infrared absorption rate per unit thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com