Special additive for slope-protection plant-growing concrete and preparation method thereof

A technology of planting raw concrete and admixtures, applied in the field of concrete admixtures, can solve the problems of single plant species, large internal alkalinity, low porosity, etc., and achieve the effects of simple raw materials, reduced alkalinity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

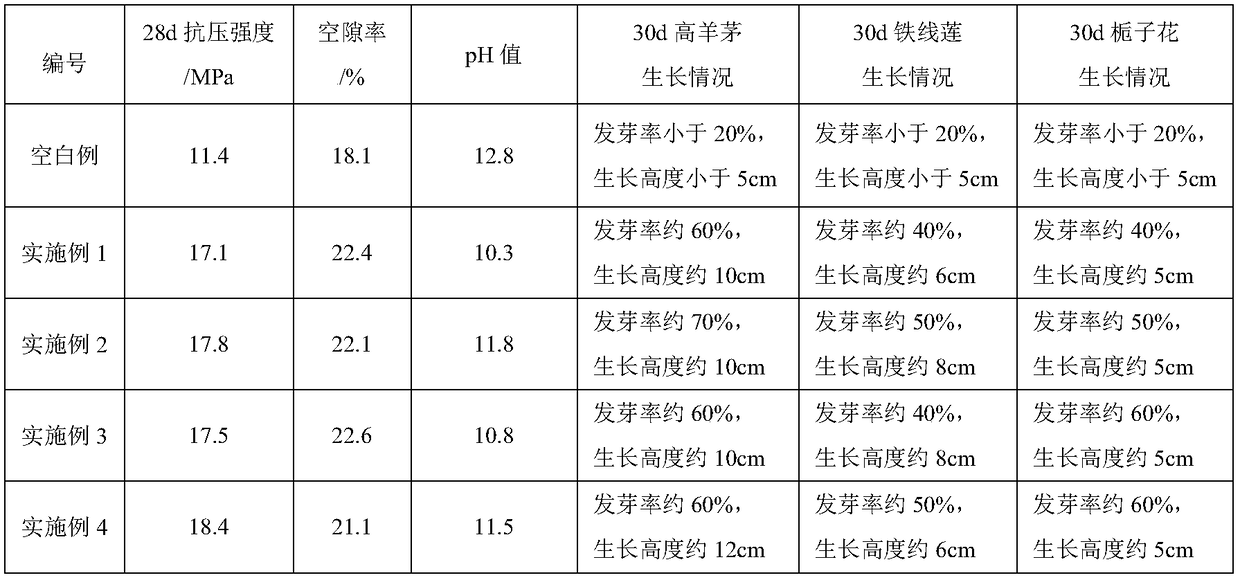

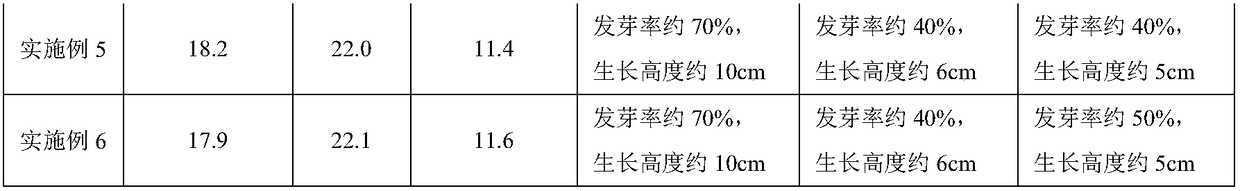

Examples

Embodiment 1

[0035] Special admixture for slope protection planting concrete and preparation method thereof, the preparation steps are as follows:

[0036] (1) Mix industrial acetic acid and water at a ratio of 1:1 to obtain an acetic acid solution, add cigarette ash and water at a ratio of 1:8, shake evenly for 1 hour, and take the supernatant to obtain incense Tobacco ash solution, after mixing the acetic acid solution and the cigarette ash solution respectively to obtain the insecticidal alkali-reducing agent, take 5 parts;

[0037] (2) Mix the washed and crushed okra with water at a ratio of 1:10, stir the mixture well for 30 minutes, let it stand for 2 hours, and then filter and collect the colorless viscous extract with a 150 μm sieve. The obtained okra extract is fully stirred to obtain the okra extract; 40 parts of the okra extract, 3 parts of polyacrylamide (molecular weight is 8 million), 30 parts of disodium dihydrogen pyrophosphate, and 27 parts of water are mixed Get the wate...

Embodiment 2

[0041](1) Mix industrial acetic acid and water at a ratio of 1:1.5 to obtain an acetic acid solution, add cigarette ash and water at a ratio of 1:8, shake evenly for 2 hours, and take the supernatant to obtain incense Tobacco ash solution, after mixing the acetic acid solution and the cigarette ash solution respectively to obtain the insecticide and alkali-reducing agent, take 7 parts;

[0042] (2) Mix the washed and crushed okra with water at a ratio of 1:20, stir the mixture well for 30 minutes, let it stand for 2 hours, and then filter and collect the colorless viscous extract with a 150 μm sieve. The obtained okra extract is fully stirred to obtain okra extract; 45 parts of okra extract, 5 parts of polyacrylamide (molecular weight is 6 million), 25 parts of disodium dihydrogen pyrophosphate, and 25 parts of water are mixed. Get the water retaining agent evenly, take 20 parts;

[0043] (3) Wash the straw with water and cut it into small pieces, dry it in an oven at 80°C fo...

Embodiment 3

[0046] (1) Mix and stir industrial acetic acid and water at a ratio of 1:1.5 to obtain an acetic acid solution, add cigarette ash and water at a ratio of 1:10, shake evenly for 2 hours, and take the supernatant to obtain incense Tobacco ash solution, after mixing the acetic acid solution and the cigarette ash solution respectively to obtain the insecticidal alkali-reducing agent, take 3 parts;

[0047] (2) Mix the washed and crushed okra with water at a ratio of 1:20, stir the mixture well for 30 minutes, let it stand for 2 hours, and then filter and collect the colorless viscous extract with a 150 μm sieve. The obtained okra extract is fully stirred to obtain okra extract; 43 parts of okra extract, 4 parts of polyacrylamide (molecular weight is 6 million), 26 parts of disodium dihydrogen pyrophosphate, and 27 parts of water are mixed Get the water retaining agent evenly, take 15 parts;

[0048] (3) Wash the straw with water and cut it into small pieces, dry it in an oven at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com