Heat-dissipation and insulating ceramic lamp shell body and preparation method thereof

An insulating shell and shell technology, which is applied in the field of heat-dissipating and insulating ceramic lamp shells and its preparation, can solve problems such as internal circuit short circuit faults, poor weathering and aging resistance, and inability to mass produce, so as to prolong the service life and glaze the surface. Beautiful and natural, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

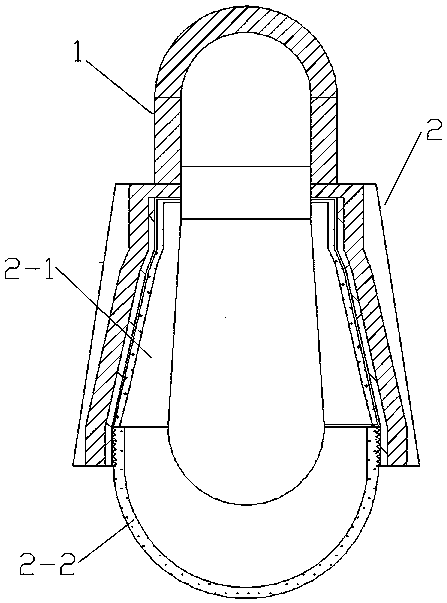

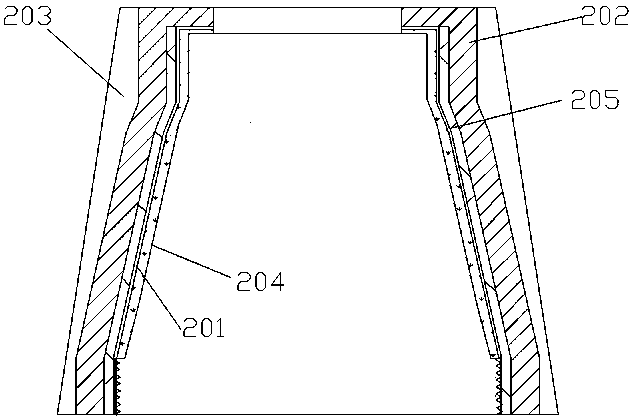

[0028] A heat-dissipating and insulated ceramic lamp housing, including a connecting lamp holder 1 and a combined housing 2, the combined housing 2 is composed of a shading cover 2-1 and a light-transmitting cover 2-2, and the shading cover 2-1 The support shell 201 including the inner layer and the heat dissipation insulation shell 202 nested outside the support shell 201, a heat conduction medium layer 205 is also arranged between the support shell 201 and the heat dissipation insulation shell 202, and the heat conduction medium layer 205 It is a graphite-based composite material. The metal material of the supporting shell 201 is made of copper, stainless steel or aluminum-magnesium alloy. The heat dissipation insulating case 202 is made of ceramic material, and heat dissipation fins 203 are arranged on the outside of the heat dissipation insulation case 202, and the heat dissipation fins 203 are in the shape of waves or vertical stripes. The supporting shell 201 is made of...

Embodiment 2

[0037] A heat-dissipating and insulating ceramic lamp housing, including a connecting lamp holder 1 and a combined housing 2, the combined housing 2 is composed of a shading cover 2-1 and a light-transmitting cover 2-2, and the shading cover 2- 1 A support shell 201 including an inner layer and a heat dissipation insulation shell 202 nested outside the support shell 201, a heat conduction medium layer 205 is also arranged between the support shell 201 and the heat dissipation insulation shell 202, and the heat conduction medium layer 205 is graphite base composite material. The metal material of the supporting shell 201 is copper, stainless steel or aluminum-magnesium alloy. The heat dissipation insulating case 202 is made of ceramic material, and heat dissipation fins 203 are arranged on the outside of the heat dissipation insulation case 202, and the heat dissipation fins 203 are in the shape of waves or vertical stripes. The supporting shell 201 is made of metal material, ...

Embodiment 3

[0046] A heat-dissipating and insulating ceramic lamp housing, including a connecting lamp holder 1 and a combined housing 2, the combined housing 2 is composed of a shading cover 2-1 and a light-transmitting cover 2-2, and the shading cover 2- 1 A support shell 201 including an inner layer and a heat dissipation insulation shell 202 nested outside the support shell 201, a heat conduction medium layer 205 is also arranged between the support shell 201 and the heat dissipation insulation shell 202, and the heat conduction medium layer 205 is graphite base composite material. The metal material of the supporting shell 201 is copper, stainless steel or aluminum-magnesium alloy. The heat dissipation insulating case 202 is made of ceramic material, and heat dissipation fins 203 are arranged on the outside of the heat dissipation insulation case 202, and the heat dissipation fins 203 are in the shape of waves or vertical stripes. The supporting shell 201 is made of metal material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com