Method for preparing fertilizer granules

A fertilizer granule and fertilizer technology, which is applied in the field of fertilizer granule preparation, can solve the problems of compaction, granular fertilizer drying, dehydration and incomplete cooling, etc., and achieve the effects of ensuring growth, low cost, and alleviating soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

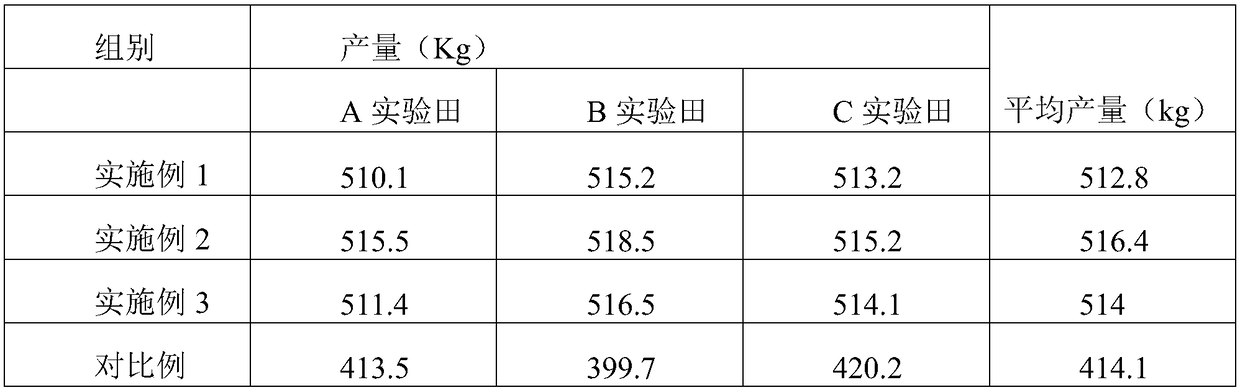

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of fertilizer granules, and the steps comprise:

[0038] 1) Stir the mixture of 10 parts of cow manure, 10 parts of pig manure, 5 parts of chicken manure, 5 parts of raw bone meal and 30 parts of sewage according to the parts by weight, and put it into the first fermentation tank for fermentation for 5-8 days;

[0039] 2) removing impurities from the mixture in step 1, and adjusting the moisture content so that the moisture content is 40%;

[0040] 3) nitrogen fertilizer, borax and clay are mixed into nitrogen fertilizer powder according to the ratio of parts by weight of 10:7:3, and the nitrogen fertilizer is urea;

[0041] 4) Grinding 40 parts of straw powder, 20 parts of grass ash, 50 parts of rice husk powder, 10 parts of soybean meal, and 5 parts of potato according to the parts by weight, put them into the second fermentation tank, and then add 200 parts of water at a temperature of 90°C , and then stir...

Embodiment 2

[0061] The present embodiment provides a kind of preparation method of fertilizer granules, and the steps comprise:

[0062] 1) According to parts by weight, a mixture of 20 parts of cow dung, 20 parts of pig manure, 10 parts of chicken manure, 10 parts of raw bone meal and 40 parts of sewage was stirred and then put into the first fermentation tank for fermentation for 8 days;

[0063] 2) removing impurities from the mixture in step 1, and adjusting the moisture content so that the moisture content is 50%;

[0064] 3) nitrogen fertilizer, borax and clay are mixed into nitrogen fertilizer powder according to the ratio of parts by weight of 10:7:3, and the nitrogen fertilizer is urea;

[0065] 4) Grinding 60 parts of straw powder, 30 parts of grass ash, 70 parts of rice husk powder, 15 parts of soybean meal, and 10 parts of potato according to the parts by weight, put them into the second fermentation tank, and then add 300 parts of water at a temperature of 100°C , and then s...

Embodiment 3

[0085] The present embodiment provides a kind of preparation method of fertilizer granules, and the steps comprise:

[0086] 1) According to parts by weight, a mixture of 15 parts of cow dung, 15 parts of pig manure, 6 parts of chicken manure, 8 parts of raw bone meal and 35 parts of sewage was stirred and put into the first fermentation tank for fermentation for 7 days;

[0087] 2) removing impurities from the mixture in step 1, and adjusting the moisture content so that the moisture content is 45%;

[0088] 3) nitrogen fertilizer, borax and clay are mixed into nitrogen fertilizer powder according to the ratio of parts by weight of 10:7:3, and the nitrogen fertilizer is urea;

[0089] 4) Grinding 50 parts of straw powder, 25 parts of grass ash, 60 parts of rice husk powder, 12 parts of soybean meal, and 6 parts of potatoes according to the parts by weight, and putting them into the second fermentation tank, and then adding water at a temperature of 950-100°C 270 parts, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com