Cellulose microsphere with uniform size, and preparation method thereof

A technology of cellulose microspheres and uniform size, applied in the field of cellulose processing, can solve the problems of irregular shape of microspheres, uneven structure, limited application, etc., and achieve narrow particle size distribution, wide application range and high concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

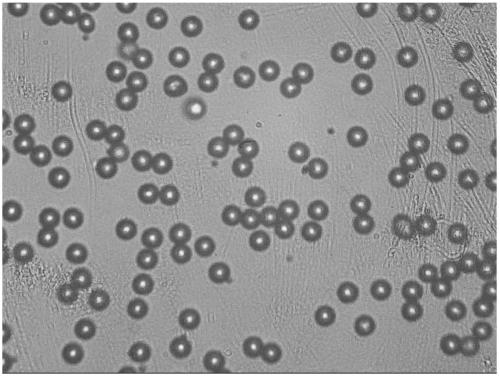

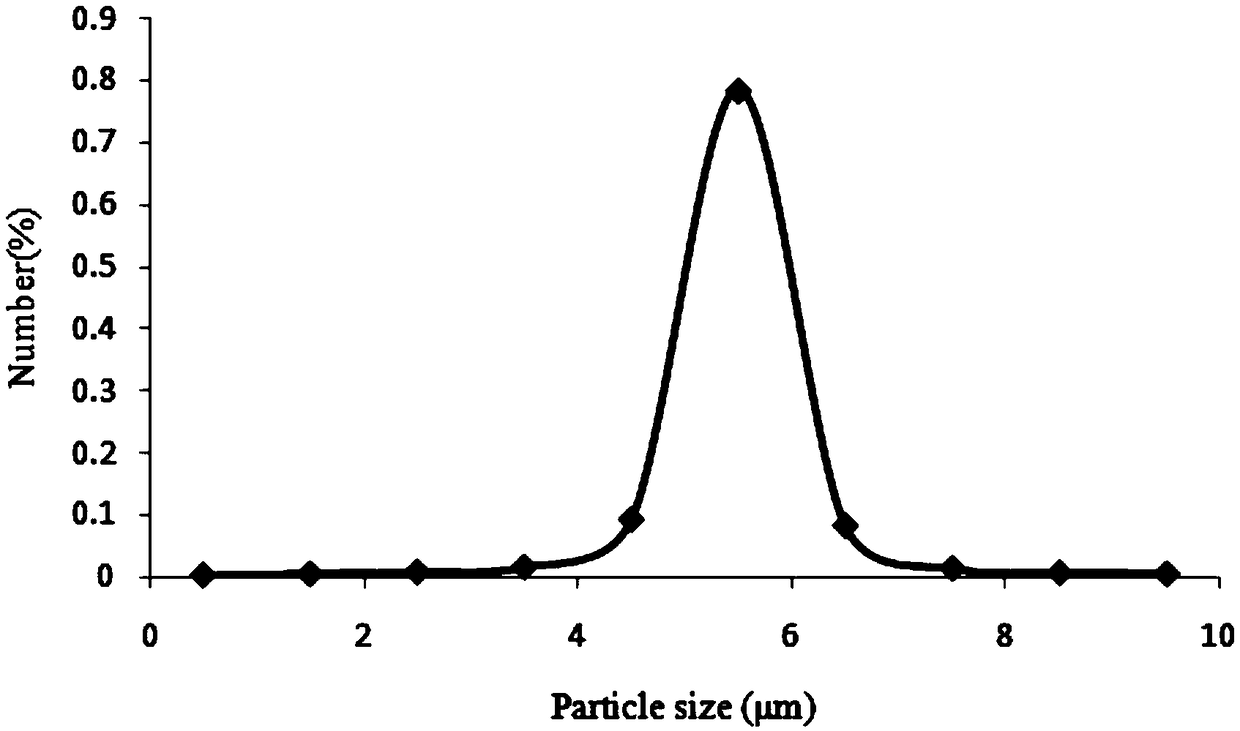

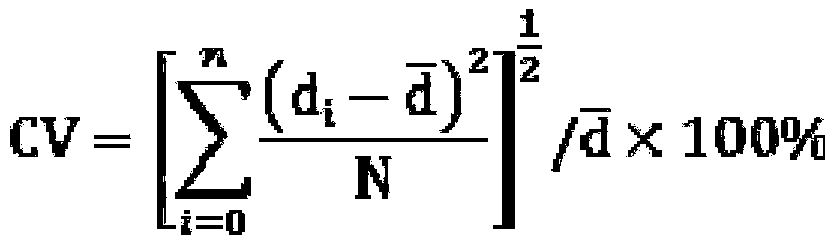

[0036]Prepare 8 kg of cellulose solution with a mass fraction of sodium hydroxide of 7.0% and a mass fraction of cellulose of 4.5%. The cellulose solution is transported to a high-speed rotary centrifugal spray dryer (manufactured by Changzhou Jiateng Drying and Granulating Equipment Co., Ltd., model LPG-5) for spray solidification, and the diameter of the atomized droplets is 0.4 μm-200 μm. The diameter of the centrifugal disc of the high-speed rotary centrifugal spray dryer is 60mm, the peripheral speed of the centrifugal disc is 130m / s, the temperature of the hot air inlet is set at 160°C, the spray volume is 5kg / h, and the weight of the solidified particles is 0.95kg. Soak the particles in water and dehydrate them. After repeated 4 times, take the leaching water and test its pH to 7.2 (indicating that the alkali has been washed), otherwise continue washing. Add the washed particles into 0.9kg of water, mix it into a uniform suspension at a stirring speed of 300r / min, and i...

Embodiment 2

[0043] It is 95kg that the mass fraction of sodium hydroxide is 7.8%, the cellulose solution that cellulose mass fraction is 6.2%. The cellulose solution is sent to a high-speed rotary centrifugal spray dryer for spray curing, and the diameter of the atomized droplets is 0.4 μm-200 μm. The diameter of the centrifugal disc of the high-speed rotary centrifugal spray dryer is 120mm, the peripheral speed of the centrifugal disc is 115m / s, the temperature of the hot air inlet is set at 128°C, the spray volume is 50kg / h, and the weight of the solidified particles is 12.4kg. Soak the particles in water and dehydrate them. After repeating this 4 times, take the rinsing water and measure the pH until it reaches 7.5 (indicating that the alkali has been washed), otherwise continue washing. Add the particles into 10kg of water, mix it into a uniform suspension at a stirring speed of 200r / min, and immediately transfer the suspension to the above-mentioned high-speed rotary centrifugal spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com