Coating technology for water-based hot melt adhesive tape

A coating process, hot melt adhesive technology, applied in the direction of adhesives, heat-activated films/sheets, film/sheet-like adhesives, etc., can solve the problems of uneven adhesive layer, stickiness, etc., and achieve uniform thickness of the adhesive layer stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

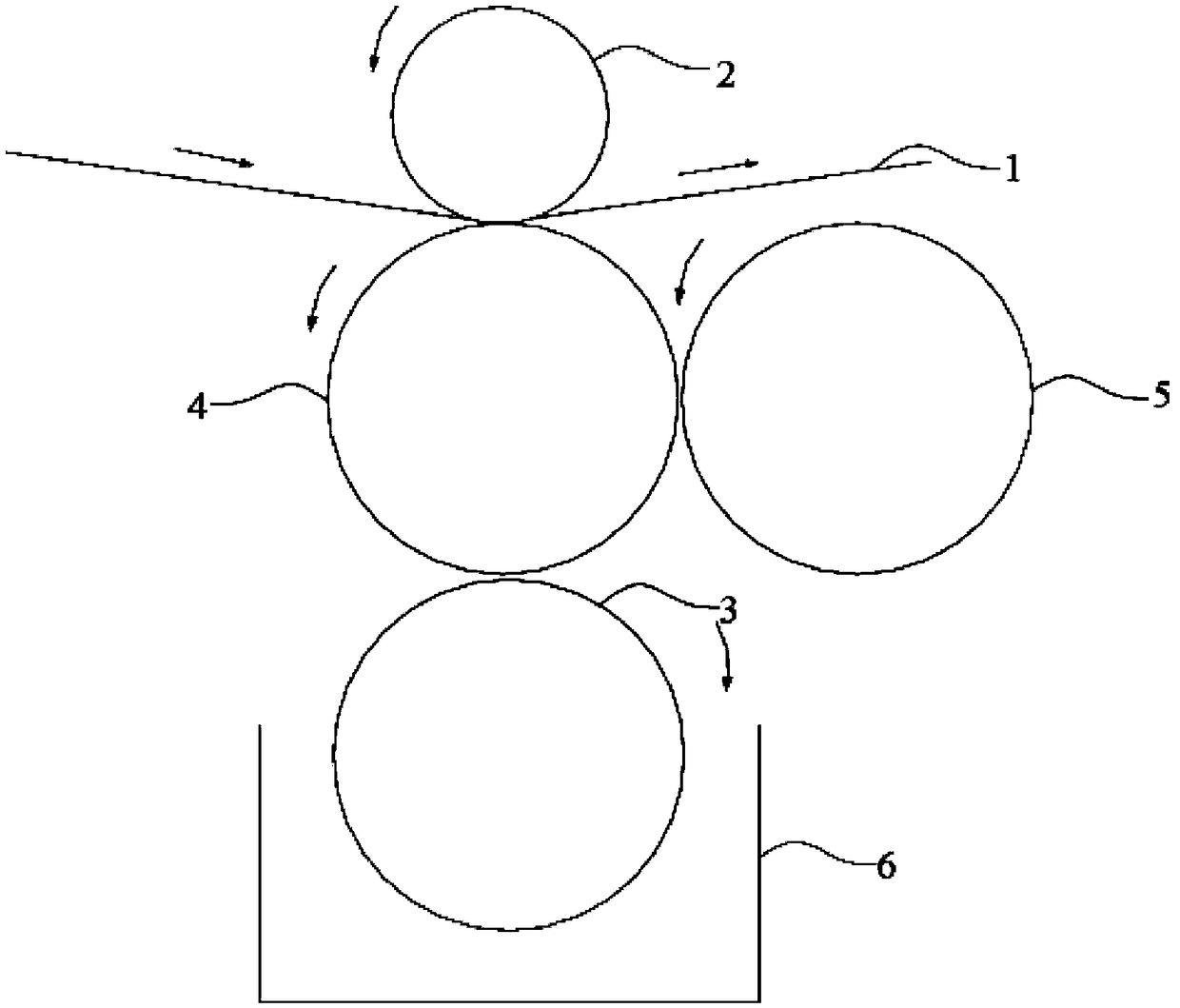

[0043] Attached below figure 1 , and further illustrate the technical solution of the present invention through specific embodiments.

[0044] The schematic flow sheet of the coating process of water-based hot-melt adhesive tape of the present invention is as figure 1 As shown, the substrate 1 is unwinding and running, and the substrate is pressed down by the pressing roller 2, so that the substrate is concave downward during operation, and the running direction of the pressing roller in contact with the substrate is the same as that of the substrate. The running direction is consistent and forms an included angle, which is convenient for glue application after contact with the upper rubber roller. Turn the rubber transfer roller 3, and the water-based hot melt glue in the glue tank 6 will be transferred from the rubber transfer roller 3 to the upper rubber roller 4. By adjusting the upper rubber roller The gap between the rubber roller 4 and the metering roller 5 is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

| Glue amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com