A method for microbial production of short, medium and long chain polyhydroxy fatty acid copolymers

A medium-to-long-chain and short-chain technology, applied in the field of microbial production of short-to-medium-to-long-chain polyhydroxy fatty acid copolymers, can solve the problems of difficult to ensure stable material performance, difficult to control, and few

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1, preparation recombinant pseudomonas

[0098] 1. Preparation of plasmid pSEVA341-Pre-phaC61-3-phaA-phaB-Kan

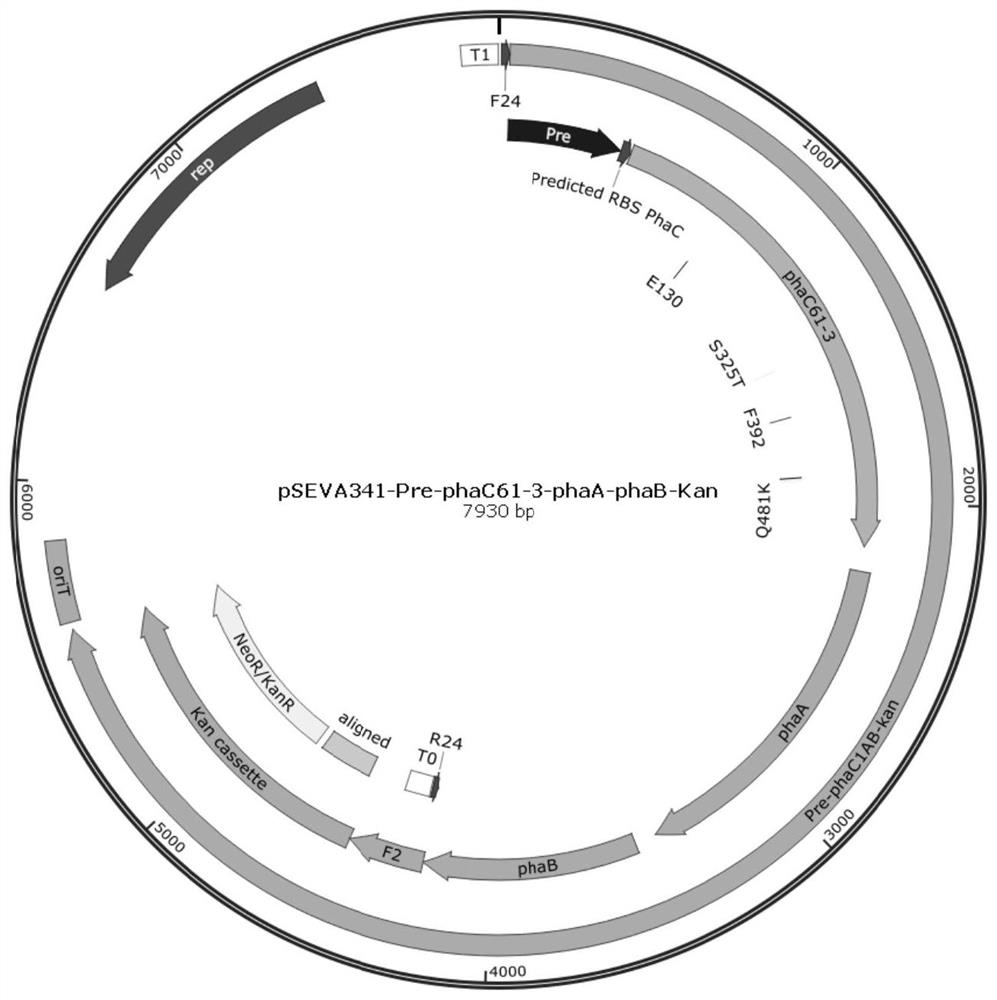

[0099] The plasmid pSEVA341-Pre-phaC61-3-phaA-phaB-Kan was prepared, as shown in sequence 1 of the sequence listing. The schematic diagram of the structure of plasmid pSEVA341-Pre-phaC61-3-phaA-phaB-Kan is as follows figure 1 Shown is a circular plasmid.

[0100] In sequence 1 of the sequence listing, nucleotides 33-428 are the Pre promoter, nucleotides 464-2143 are the phaC61-3 gene, nucleotides 2228-3409 are the phaA gene, and nucleotides 3484-4224 The first nucleotide is the phaB gene, and the 4780-5574th nucleotide is the kanamycin resistance gene.

[0101] 2. Preparation of P.entomophila LAC31 (pSEVA341-Pre-phaC61-3-phaA-phaB-Kan)

[0102] 1. Introduce the plasmid pSEVA341-Pre-phaC61-3-phaA-phaB-Kan into Escherichia coli S17-1 to obtain recombinant bacteria named E.coli S17-1 (pSEVA341-Pre-phaC61-3-phaA-phaB-Kan ).

[0103] 2. Co-cultivat...

Embodiment 2

[0121] Embodiment 2, application of recombinant Pseudomonas to produce P(3HB-co-3HDD)

[0122] 1. Application of P.entomophila LAC31 (pSEVA341-Pre-phaC61-3-phaA-phaB-Kan)

[0123] 1. Prepare the seed liquid of P. entomophila LAC31 (pSEVA341-Pre-phaC61-3-phaA-phaB-Kan).

[0124] 2. Fermentation with glucose as the sole carbon source

[0125] Take 2.5mL of the seed solution obtained in step 1, inoculate it into 47.5mL of fermentation medium, and culture it with shaking at 30°C and 200rpm for 48 hours. Fermentation medium: LB medium containing 50mg / L kanamycin and 25g / L glucose.

[0126] 3. Fermentation with glucose and lauric acid as carbon sources

[0127] Take 2.5mL of the seed solution obtained in step 1, inoculate it into 47.5mL of fermentation medium, and culture it with shaking at 30°C and 200rpm for 48 hours. Fermentation medium: LB medium containing 50mg / L kanamycin, 20g / L glucose and 5g / L lauric acid.

[0128] 4. Determination of dry cell weight, PHA content of bacte...

Embodiment 3

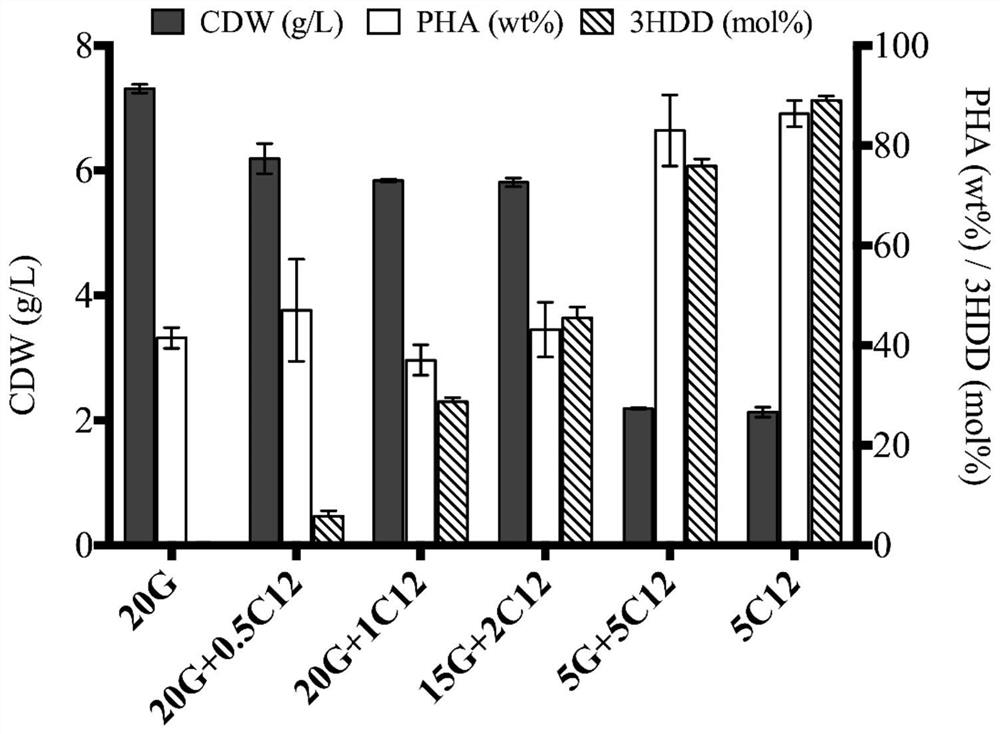

[0146] Example 3, Synthesis of P(3HB-co-3HDD) in different proportions with P.entomophila LAC32

[0147] 1. Prepare the seed solution of P. entomophila LAC32 (pSEVA341-Pre-phaC61-3-phaA-phaB-Kan).

[0148] 2. Fermentation

[0149] Take 2.5mL of the seed solution obtained in step 1, inoculate it into 47.5mL of fermentation medium, and culture it with shaking at 30°C and 200rpm for 48 hours.

[0150] The fermentation medium is any of the following:

[0151] Fermentation medium 20G: LB medium containing 50mg / L kanamycin and 20g / L glucose;

[0152] Fermentation medium 20G+0.5C12: LB medium containing 50mg / L kanamycin, 20g / L glucose and 0.5g / L lauric acid;

[0153] Fermentation medium 20G+1C12: LB medium containing 50mg / L kanamycin, 20g / L glucose and 1g / L lauric acid;

[0154] Fermentation medium 15G+2C12: LB medium containing 50mg / L kanamycin, 15g / L glucose and 2g / L lauric acid;

[0155] Fermentation medium 5G+5C12: LB medium containing 50mg / L kanamycin, 5g / L glucose and 5g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com