Control system for sheet substrate vacuum coating production line

A control system and vacuum coating technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of inconvenient data management, cumbersome electric cabinet wiring, low production efficiency, etc., and achieve data exchange Fast and convenient, clear programming address distribution, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

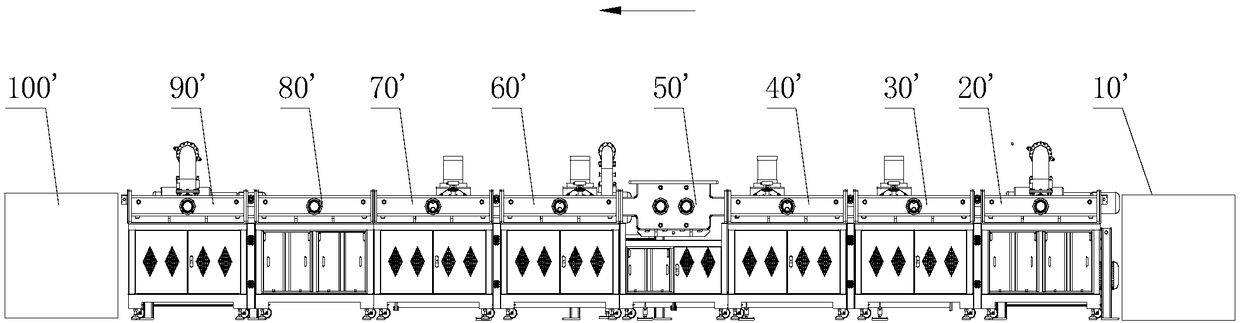

[0025] Such as figure 1 As shown, a sheet-type substrate vacuum coating production line, which sequentially includes a loading table 10', a film feeding chamber 20', a heating chamber 30', a front buffer chamber 40', and three mutually independent The magnetron sputtering vacuum coating chamber 50', 60', 70', the rear buffer chamber 80', the cooling chamber 90' and the unloading table 100' also include a transport mechanism for transporting the substrate (not shown in the figure ).

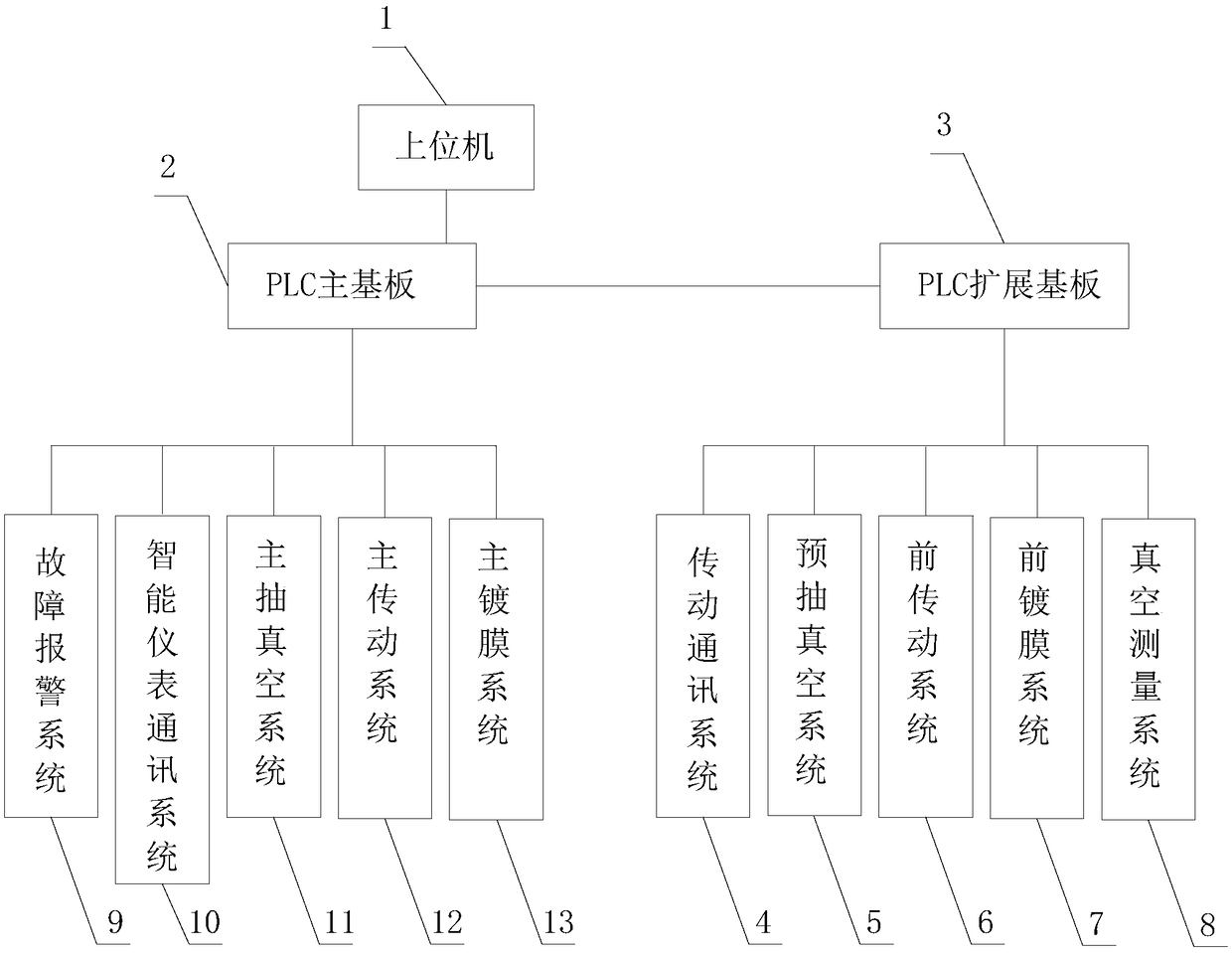

[0026] Such as figure 2 As shown, the present invention matches the control system of the above-mentioned chip substrate vacuum coating production line, including a host computer 1, and a PLC main substrate 2 connected to the host computer 1 by Ethernet communication, and the PLC main substrate 2 is connected to There is a PLC extension substrate 3, the PLC extension substrate 3 is connected with a transmission communication system 4, a pre-vacuum system 5, a front transmission system 6, a fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com