Optical module test system and method

A technology for optical module testing and light source modules, applied in transmission systems, electromagnetic wave transmission systems, electrical components, etc., can solve problems such as reducing test efficiency, cumbersome testing procedures, and increasing production costs, reducing software management work and enhancing reliability. , the effect of enhancing the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

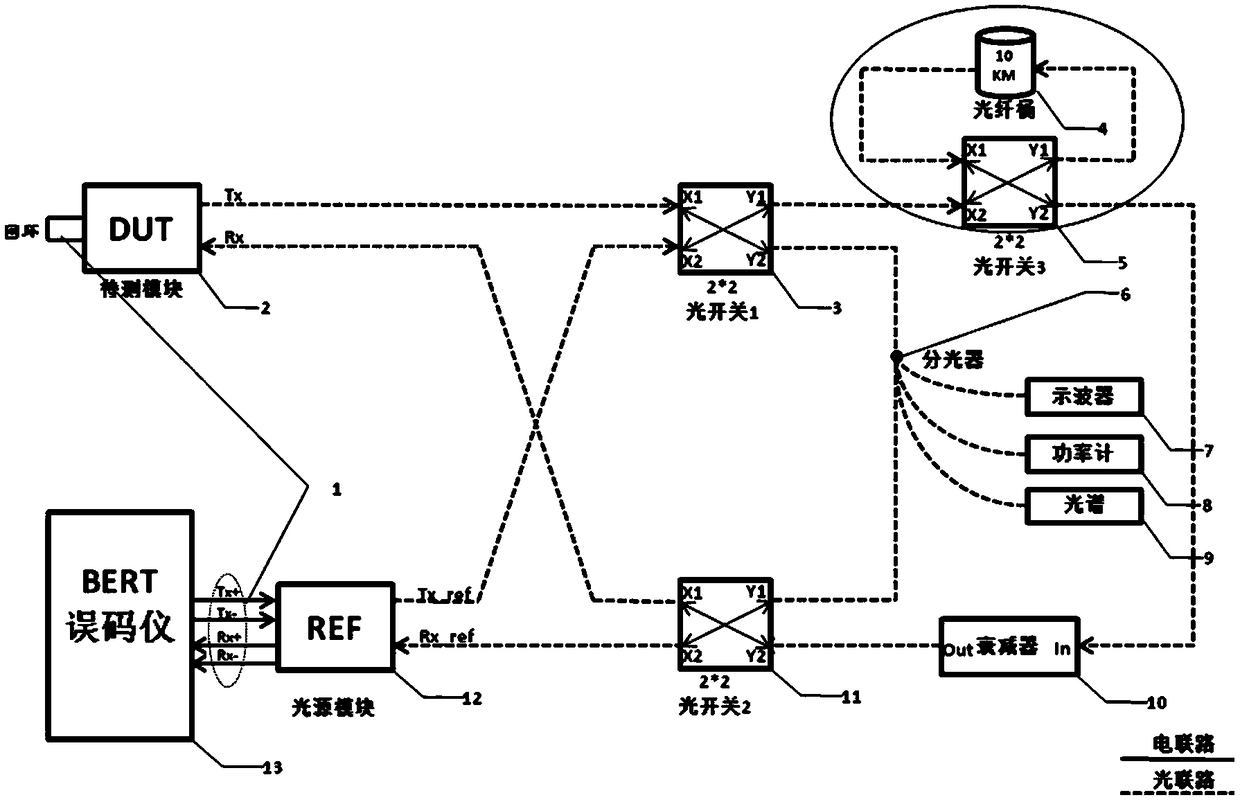

[0020] A kind of optical module test system, such as figure 1 As shown, the equipment list includes:

[0021] serial number

name

serial number

name

1

8

2

9

3

10

4

11

5

12

Light source module

6

1 / 4 optical splitter

13

BERT

7

14

/

[0022] The DUT electrical ports Tx+ / - and Rx+ / - of the module to be tested are connected by a coaxial cable to realize a loopback connection, so that the modulated signal generated by the bit error detector is converted from an electrical signal to an optical signal by the light source module, and then transmitted to the module to be tested by the link. The end is converted from an optical signal to an electrical signal and loaded to the transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com