Method for obtaining round collagen casing and casing obtained by the same

A collagen casing and round technology, which is applied in the field of obtaining round collagen casings, can solve the problems of weak round casings and periodic production interruptions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Post-rounding, eg, of a straight collagen NDX casing caliber 21 sold by Viscofan S.A. / Spain with 22% moisture relative to its total weight and 17% glycerol as plasticizer, by heat shrinking.

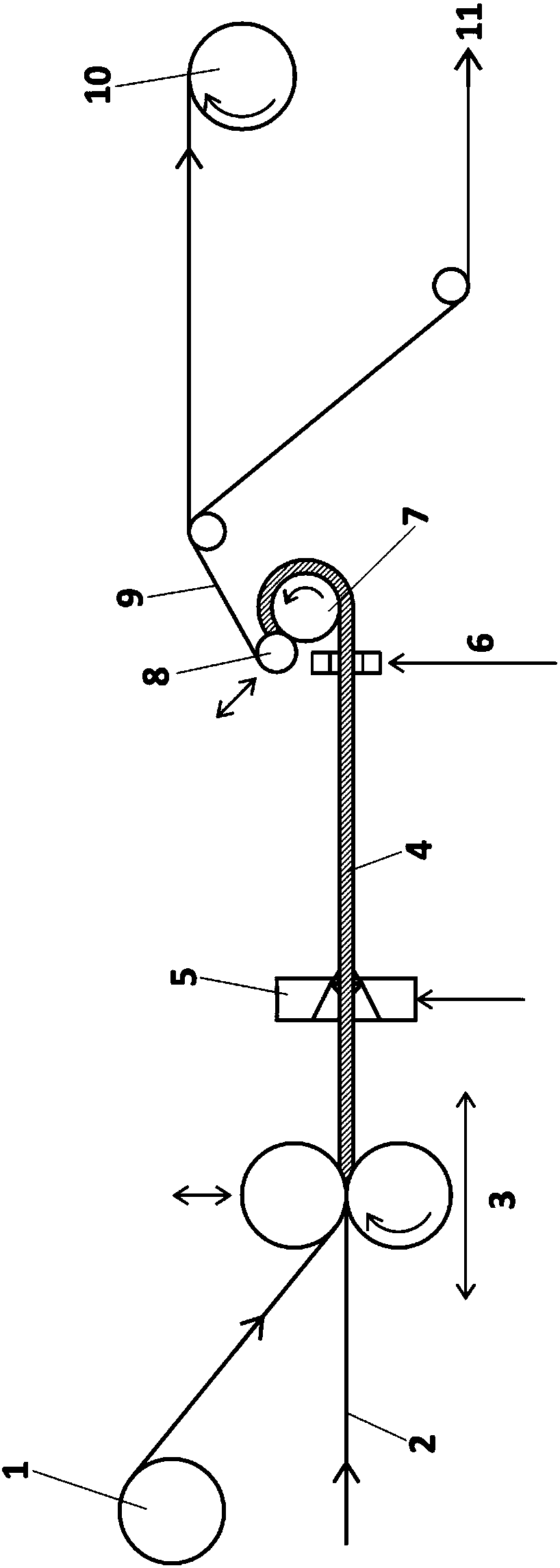

[0064] Parent rolls of chemically cross-linked NDX casings (1) are manually unwound, conveyed through conveyor roller pairs (3) and further passed through annular fans (6) around heat regulating rollers (7) to heated regulating rollers (7) ) and a small roller (8) composed of a pair of receiving rollers, such as figure 1 shown.

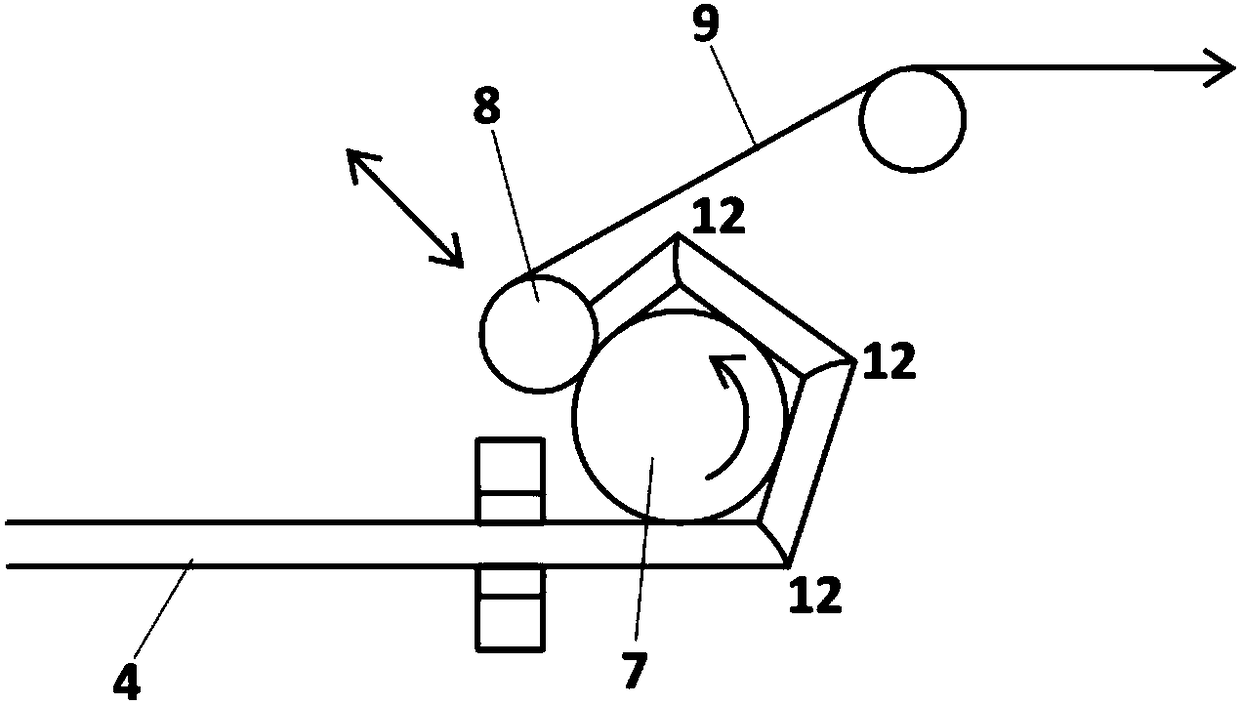

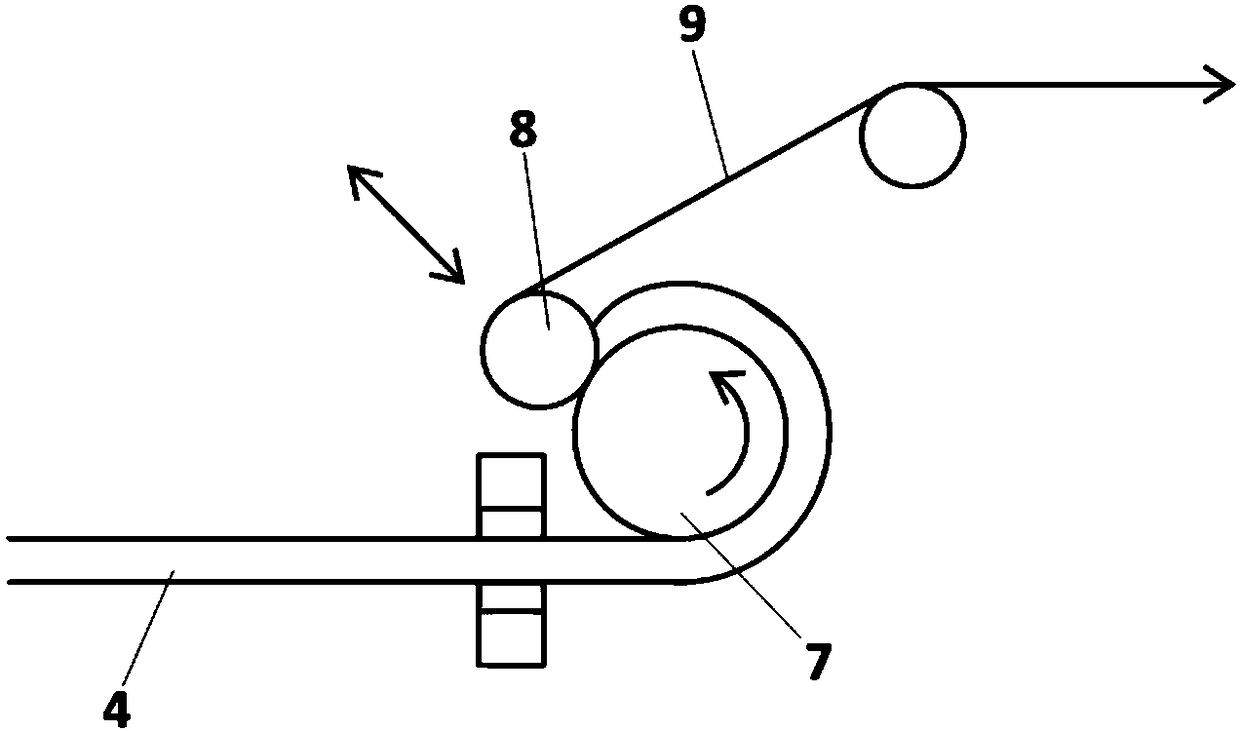

[0065] The NDX casing is aerated to 200 mbar and its bubbles are captured between the conveyor roller pair (3) and the roller pair formed by the hot regulating roller (7) and the small roller (8). Then, the casing bubble (4) tightly surrounds 3 / 4 around the heat regulating roller with a diameter of 115mm. Thus, the casing bubble (4) forms a radial bend (12) along its innermost ring (13), as Figure 2a shown.

Embodiment 2

[0080] Rolls of straight collagen casing Colfan B gauge 19 sold by Viscofan S.A. / Spain were post-rounded by applying the same technique as described in Example 1 of the present invention.

[0081]

[0082] No collagen is "rubbed away".

[0083] Sir / Sor 1.35

[0084] The casing of the full circle after the gain of the embodiment of the present invention 2 is further compared with the casings of comparative examples A and B, the casings of comparative examples A and B:

[0085] Clear visual detection of collagen "rubbed off" along the inner ring.

[0086] Sir / Sor 1.19

Embodiment 3

[0088] R2L-SR is a non-edible straight collagen casing sold by Viscofan S.A. Pamplona / Spain. It was rounded after the line according to the following embodiment 1 of the present invention.

[0089] first along figure 1 The casing collector buffer not shown in the guide to compensate for speed deviations leads directly from the R2L caliber 39 of the product dryer.

[0090] Such as figure 1 Described, casing moisture improves when passing through water ring sprayer (5).

[0091] Post-rounding of R2L-SR was performed as described in Example 1 of the present invention.

[0092]

[0093] No collagen is "rubbed away".

[0094] Sir / Sor 1.30

[0095] The casing of the full circle after the gain of the embodiment of the present invention 3 is directly compared with the casing of comparative example C, and the casing of comparative example C:

[0096] Clear visual detection of collagen rubbed off along the inner ring.

[0097] Sir / Sor 1.10

[0098] After the full round casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com