Down-drain sludge microwave pyrolysis system and method for product collection

A bottom-out, microwave technology, applied in the direction of by-product vaporization, pyrolysis treatment of sludge, etc., can solve the problems that cannot represent the reaction temperature of sludge, affect the separation and collection of solid products and liquid products, and interfere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

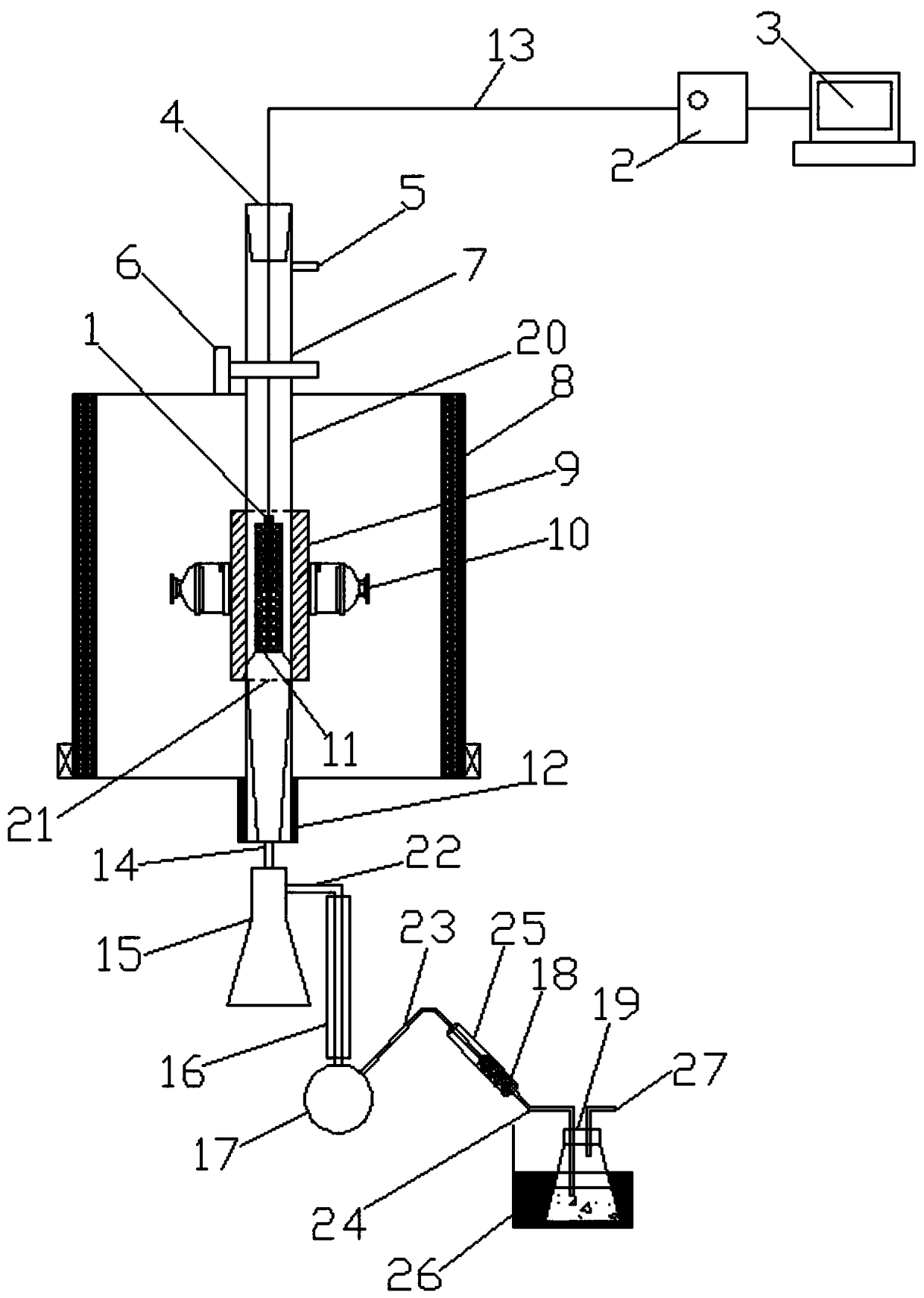

[0030] Such as figure 1 As shown, a bottom-out sludge microwave pyrolysis system for product collection includes a microwave oven 8, an Erlenmeyer flask 15 located at the bottom of the microwave oven 8 and sealed by a bottle stopper, located on one side of the Erlenmeyer flask 15 and sealed by a bottle stopper Sealed flask 17, a gas washing bottle 19 located on one side of the flask 17 and sealed by a bottle stopper; as a preferred method, for better reflux of liquid products and effective separation of gas products, the flask 17 is located in the Erlenmeyer flask 15 The lower part, the washing bottle 19 is located at the bottom of the flask 17;

[0031]The microwave oven 8 is suspended and fixedly installed, and the microwave oven 8 has a microwave oven cavity 21 and two microwave magnetrons 10; the two microwave magnetrons 10 are fixed on opposite sides of the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com