Method for relieving structure collapse of steamed buns by using sour dough fermentation technology

A technology for fermentation of sourdough and lactic acid bacteria is applied in the field of improving the structure collapse of steamed bread, which can solve the problems of irradiation residue, product quality damage, component denaturation, etc., and achieves the improvement of internal shrinkage, product quality, shrinkage and collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

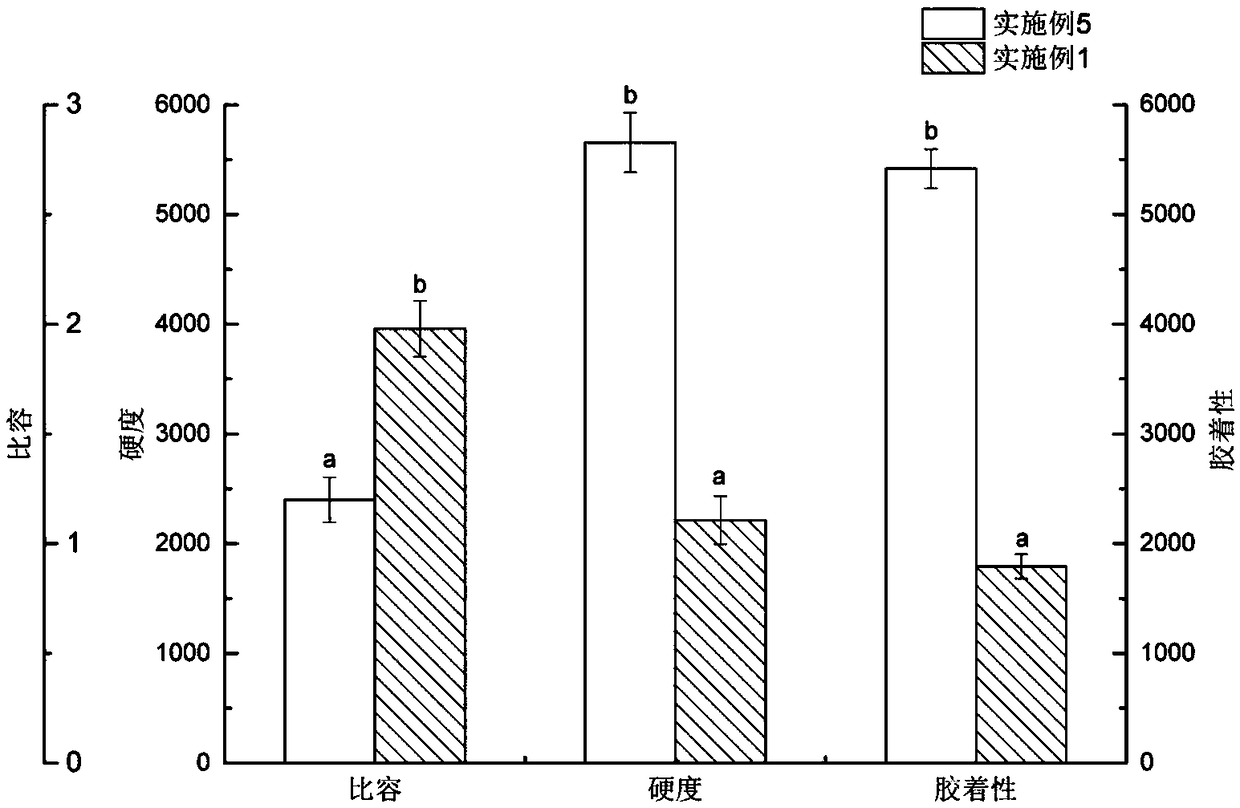

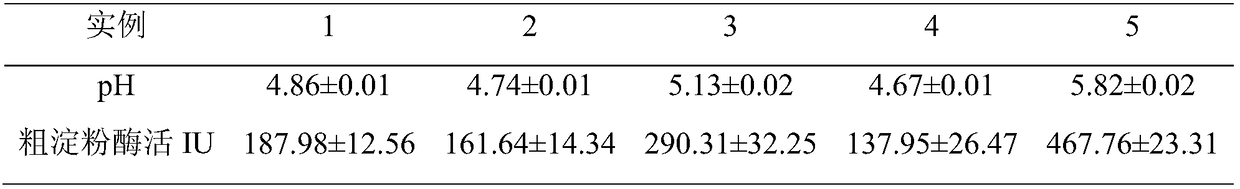

Embodiment 1

[0034] Weigh 90 parts by weight of rye flour and 300 parts by weight of medium-gluten wheat flour, and mix them uniformly to form wheat flour with high amylase activity.

[0035](1) Preparation of lactic acid bacteria fermented sourdough: take 1.5 parts by weight of active Lactobacillus plantarum freeze-dried bacteria powder, add 90 parts by weight of water and 90 parts by weight of wheat flour with high amylase activity, mix uniformly, and place in a constant temperature incubator , the temperature of the incubator was set to 35°C, and the temperature was incubated for 12 hours;

[0036] (2) Preparation of high-amylase live wheat flour dough: take by weighing 300 parts by weight of wheat flour with high-amylase activity, 180 parts by weight of sour dough made by lactic acid bacteria fermentation in step (1), 3 parts by weight of Angel yeast powder and 85 parts by weight A portion of water is placed in a mixing tank, and stirred to obtain a mixed dough for making steamed buns;...

Embodiment 2

[0040] Weigh 90 parts by weight of rye flour and 300 parts by weight of medium-gluten wheat flour, and mix them uniformly to form wheat flour with high amylase activity.

[0041] (1) Preparation of lactic acid bacteria fermented sourdough: take 1.5 parts by weight of active Lactobacillus plantarum freeze-dried bacteria powder, add 90 parts by weight of water and 90 parts by weight of wheat flour with high amylase activity, mix uniformly, and place in a constant temperature incubator , the temperature of the incubator was set to 35°C, and the temperature was incubated for 12 hours;

[0042] (2) Preparation of high amylase active wheat flour dough: take by weighing 300 parts by weight of wheat flour with high amylase activity, 200 parts by weight of sour dough made by lactic acid bacteria fermentation in step (1), 3 parts by weight of Angel yeast powder and 58 parts by weight A portion of water is placed in a mixing tank, and stirred to obtain a mixed dough for making steamed bu...

Embodiment 3

[0046] Weigh 90 parts by weight of rye flour and 300 parts by weight of medium-gluten wheat flour, and mix them uniformly to form wheat flour with high amylase activity.

[0047] (1) Preparation of lactic acid bacteria fermented sourdough: take 1.5 parts by weight of active Lactobacillus plantarum freeze-dried bacteria powder, add 90 parts by weight of water and 90 parts by weight of high amylase live wheat flour, mix uniformly, place a constant temperature incubator, The temperature of the incubator was set at 35°C and incubated at constant temperature for 12 hours;

[0048] (2) Preparation of high-amylase live wheat flour dough: take by weighing 300 parts by weight of high-amylase live wheat flour, 120 parts by weight of sour dough made by lactic acid bacteria fermentation in step (1), 3 parts by weight of Angel yeast powder and 85 parts by weight Water is placed in the mixing tank, and stirred to obtain a mixed dough for making steamed buns;

[0049] (3) Proofing and steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com