An arc length measuring device and method thereof

An arc length and measuring device technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inconvenient direct measurement and inaccurate arc length measurement results, achieve clear position information and scale information, and save measurement time. , the effect of easy extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A specific embodiment of the present invention discloses an arc length measuring device, such as figure 1 As shown, including arc generating device, transparent tape scale device, high-speed camera. Wherein, the pellucida scale device is arranged on one side of the nozzle of the arc generating device when the image before welding is taken, parallel to the axis of the nozzle of the arc generating device, and the high-speed camera is arranged between the pellucida scale device and the The preset position opposite to the nozzle of the arc generating device. The layout position of the high-speed camera should be such that the nozzle of the arc generator and the scale device of the transparent tape are located within the viewing range of the high-speed camera.

[0064] The arc generating device is used to generate an arc at the nozzle through its electrodes after being energized.

[0065] Transparent tape graduated device for measuring the arc length of the arc generated b...

Embodiment 2

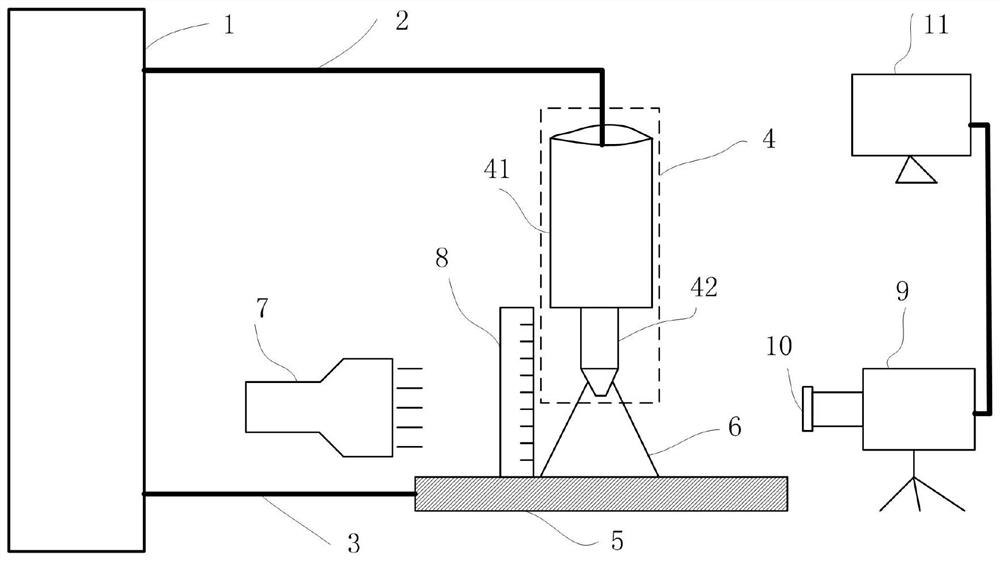

[0071] Optimizing on the basis of the above examples, such as figure 2 As shown, the arc generating device includes a welding power source 1 , cables 2 and 3 , and a welding torch 4 . In the figure, the position of the transparent band scale device 8 is only for illustration, and does not represent the real position, which should overlap with the welding gun 4 . The welding power supply 1 is connected to the welding torch 4 through the cable 2 and connected to the workpiece 5 through the cable 3 , and the nozzle 41 of the welding torch 4 is vertically arranged above the workpiece 5 to be processed.

[0072] The welding power source 1 is used to supply power to the electrode of the welding torch 4 and the workpiece 5 to be processed through the cables 2 and 3 . One output end of the welding power source 1 is connected to the electrode of the welding torch 4 through the cable 2, and the other output end of the welding power source 1 is connected to the workpiece to be processe...

Embodiment 3

[0084] Another specific embodiment of the present invention discloses a method for measuring arc length using the arc length measuring device described in Embodiment 2, such as Figure 6 shown, including the following steps:

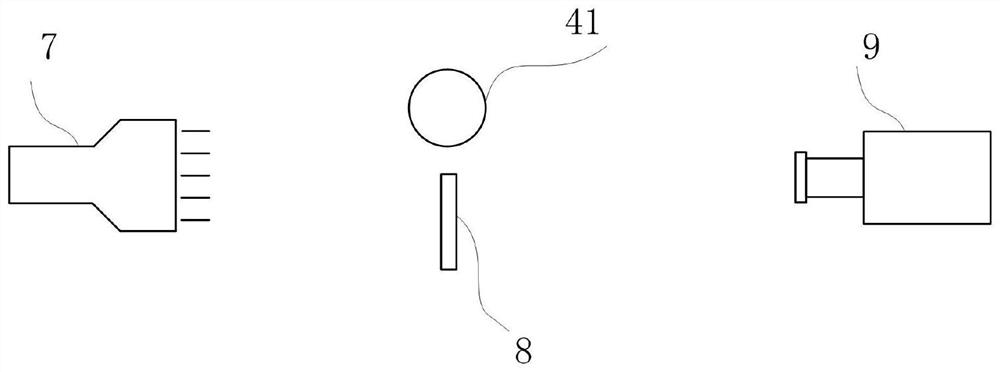

[0085] S1. Arrange the arc length measuring device, set the transparent belt scale device 8, the backlight source 7, turn on the backlight source 7, and adjust the brightness of the backlight source 7. Adjust the distance from the high-speed camera to the welding torch and from the backlight source to the welding torch, so that the high-speed camera, electrodes, and backlight source are on the same straight line.

[0086] S2. Adjust the shooting angle and aperture of the high-speed camera 9 .

[0087] S3. Collect the pre-welding image through the high-speed camera 9 .

[0088] S4. After the collection is completed, remove the backlight light source 7 and the transparent tape scale device 8, install the light-reducing film 10, and adjust the light inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com