Modularized movable type prefabricated part multilayer steam curing production system and installation production method

A prefabricated component, mobile technology, used in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high capital investment and maintenance costs for prefabricated buildings, shorten the construction period, reduce the total project cost, and reduce prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

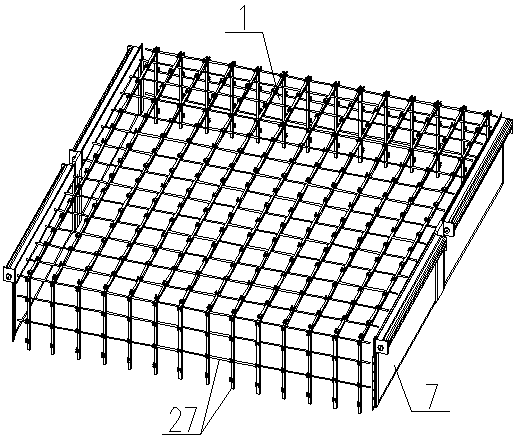

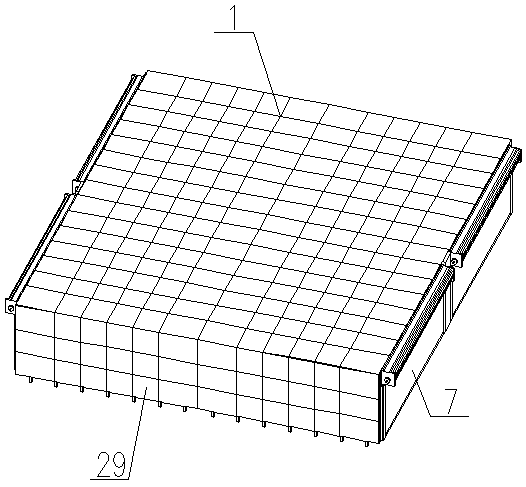

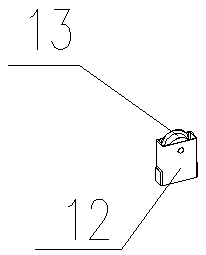

[0049] A modular mobile prefabricated component multi-layer steam-curing production system, its composition includes: steam-curing shed 1, mold table moving line 5, ferry car 6 and moving machine 19, said steam-curing shed is a linear closed space, The open-type shed door 7 is set on the steaming shed, and the moving line of the mold platform is two linearly arranged ground wheels 10 and a drive motor 11. The ground wheel has a support frame 12, and the support frame Wheels 13 are arranged on the top, and a drive motor is set between the ground wheels. The drive motor wheel 14 is an annular friction surface, and the ferry car is a horizontal moving device for a mold table. The top of the frame is provided with a jacking device 16, the bottom of the frame is provided with traveling wheels 17, the traveling wheels are provided with a driving device, the lower part of the wheels is provided with a traveling track, and the production system is arranged in parallel with N groups of ...

Embodiment 2

[0052] According to the modular mobile prefabricated component multi-layer steam curing production system described in embodiment 1, the steam curing shed is provided with an auxiliary heating device, and the mold table moving line is provided with a mold table cleaning station for the production of prefabricated components, Marking station, formwork station, painting release agent station, rib binding station, pre-embedded parts pre-embedded station, cloth station, vibrating station, post-processing station, formwork removal and lifting station .

Embodiment 3

[0054] According to the modular mobile prefabricated component multi-layer steam-curing production system described in embodiment 1 or 2, the steam-curing shed uses a quick-release frame as the shed body skeleton 27, and the bottom foundation of the frame main body skeleton is the first A prefabricated foundation 28, the heat-absorbing heat preservation panel 29 is closed outside the frame body, the bottom foundation of the vibrator is the second prefabricated foundation 30, and the bottom foundation of the pouring system distribution machine auxiliary frame body is the third prefabricated foundation 31 , the bottom foundation of the ferry vehicle running track is the fourth prefabricated foundation 32, the bottom foundation of the ground wheel is the fifth prefabricated foundation 33, the bottom foundation of the drive motor is the sixth prefabricated foundation 34, and the moving machine The bottom foundation of the walking track is the seventh prefabricated foundation 37, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com