Environment-friendly degradable bubble packaging bag and manufacturing process thereof

An environmentally friendly packaging bag technology, applied in the field of bubble packaging bags, can solve problems such as poor use effect and complex structure of packaging bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

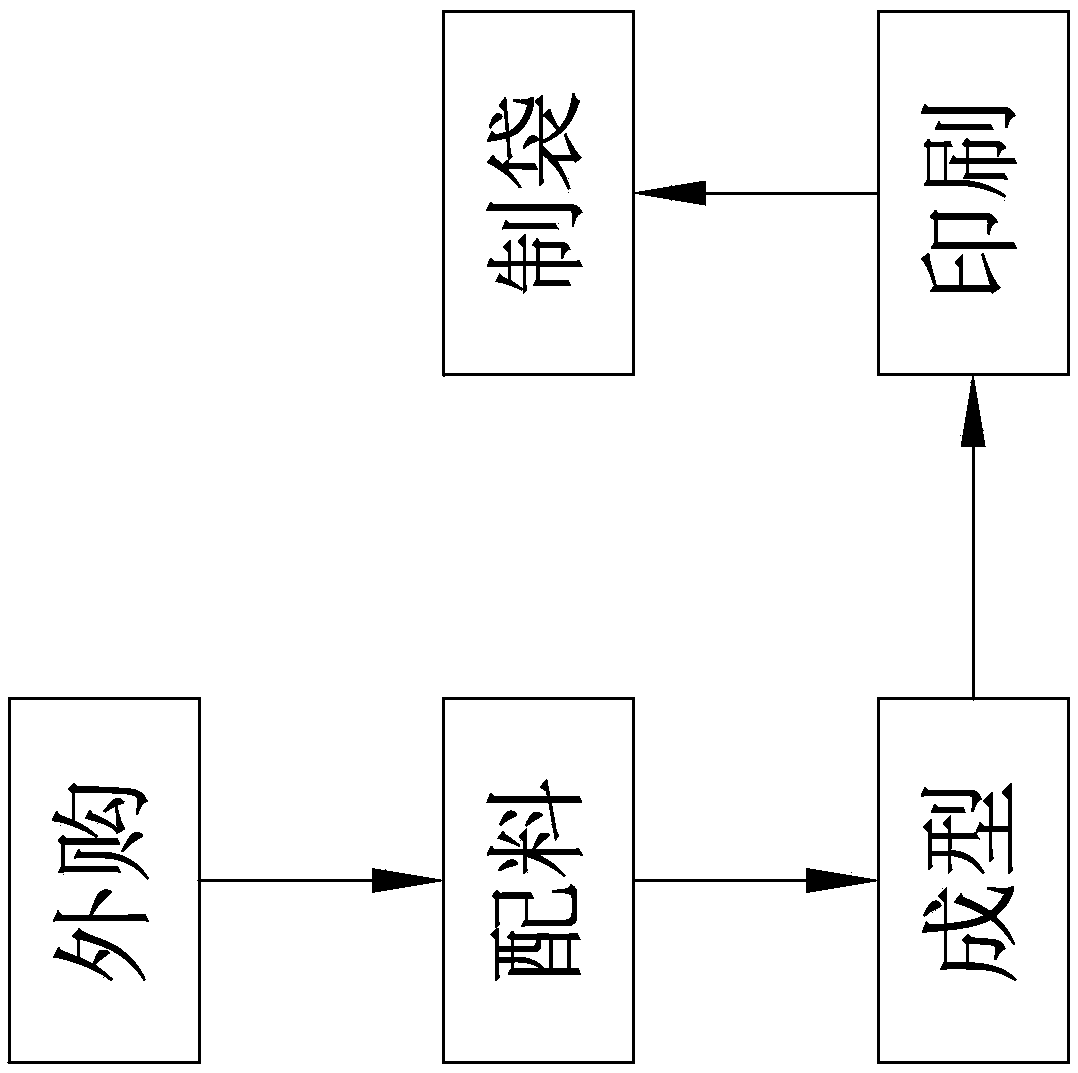

[0092] The manufacturing process of the environment-friendly degradable bubble packaging bag comprises the following steps:

[0093] a. Outsourcing: buy the existing film on the market as the mask layer; 86% polyethylene, 4% flame retardant, 3% plasticizer and 7% biodegradable additive;

[0094]b. Ingredients: put 87% polyethylene, 5% plasticizer and 8% biodegradable additive into the mixer according to mass percentage, and stir for 50min to obtain mixture 1; mix 83% polyethylene, 5% antistatic agent , 6% of the plasticizer and 6% of the biodegradable additive were put into the mixer, and stirred for 40 minutes to obtain the mixture 2;

[0095] c. Forming: Extrude and form mixture 1 through the processing system, the forming temperature is 180°C, so that it forms a bubble film layer on the mask layer; then extrude and form mixture 2 through the processing system, the forming temperature is 173 ℃, so that it forms a coating layer on the bubble film layer to make a composite fi...

Embodiment 2

[0099] The manufacturing process of the environment-friendly degradable bubble packaging bag comprises the following steps:

[0100] a. Outsourcing: buy the existing film on the market as the mask layer; 86% polyethylene, 4% flame retardant, 3% plasticizer and 7% biodegradable additive;

[0101] b. Ingredients: put 90% polyethylene, 4% plasticizer and 6% biodegradable additive into the mixer according to mass percentage, and stir for 45 minutes to obtain mixture 1; mix 85% polyethylene and 3% antistatic agent , 6% of the plasticizer and 6% of the biodegradable additive were put into the mixer, and stirred for 35 minutes to obtain the mixture 2;

[0102] c. Molding: Extrude and shape the mixture 1 through the processing system. The molding temperature is 178°C to form a bubble film layer on the mask layer; then extrude the mixture 2 through the processing system and shape it. The molding temperature is 168°C. ℃, so that it forms a coating layer on the bubble film layer to make...

Embodiment 3

[0106] The manufacturing process of the environment-friendly degradable bubble packaging bag comprises the following steps:

[0107] a. Outsourcing: buy the existing film on the market as the mask layer; 86% polyethylene, 4% flame retardant, 3% plasticizer and 7% biodegradable additive;

[0108] b. Ingredients: put 82% of polyethylene, 8% of plasticizer and 10% of biodegradable additive into the mixer according to mass percentage, and stir for 60 minutes to obtain mixture 1; mix 75% of polyethylene and 7% of antistatic agent , 8% of the plasticizer and 10% of the biodegradable additive were put into the mixer, and stirred for 50 minutes to obtain the mixture 2;

[0109] c. Molding: Extrude and shape the mixture 1 through the processing system at a molding temperature of 182°C to form a bubble film layer on the mask layer; then extrude and shape the mixture 2 through the processing system at a molding temperature of 176°C ℃, so that it forms a coating layer on the bubble film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com