Composite material, automobile spare tire cover and preparation method thereof

A composite material and spare tire cover technology, which is applied in spare tire layout, chemical instruments and methods, vehicle parts, etc., can solve the problems of spare tire cover deformation, thick thickness, and high grammage, so as to improve product competitiveness and reduce Costs, Multiple Choice Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

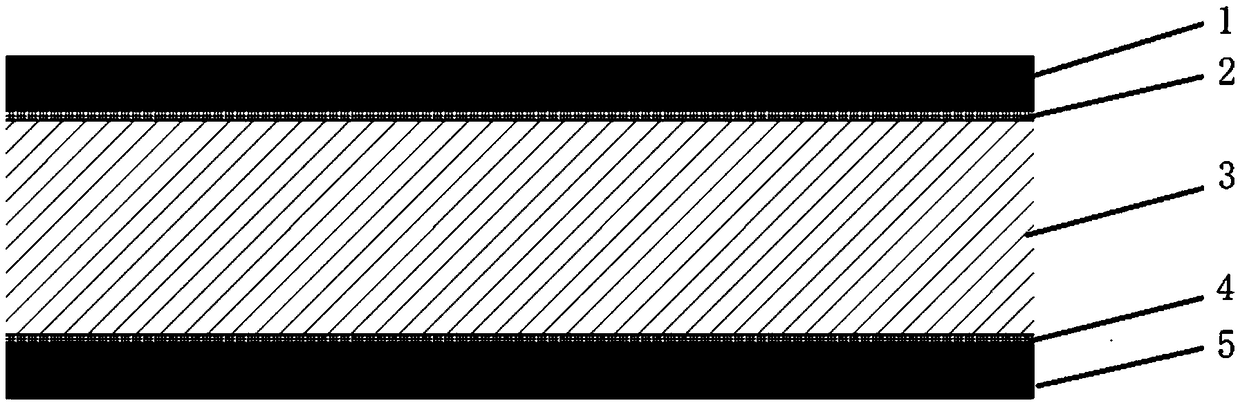

[0023] see figure 1 and figure 2 , in this embodiment, the composite material designed by the present invention has a five-layer structure, which is a high-strength epoxy resin layer, a glass fiber felt layer, a high-strength epoxy resin layer, a glass fiber felt layer, and a high-strength epoxy resin layer from top to bottom. Layers of strength epoxy resin, each layer is bonded by glue. The third layer of high-strength epoxy resin layer is the middle layer of the odd-numbered core layer, and the epoxy resin layer of the middle layer is covered up and down by the glass fiber felt layers on the upper and lower sides. The advantages of the composite material are: the combination of glass fiber felt and epoxy resin can effectively reduce the weight and thickness of the material under the condition of satisfying its bearing capacity performance, and realize the purpose of light weight; at the same time, it can also prevent moisture and mildew , Mothproof, etc., while effectivel...

Embodiment 2

[0026] Adopt the method of the present invention to prepare the spare tire cover of certain vehicle type, its part size is: 1000*840mm, used composite material, comprises epoxy resin, fiberglass felt, and described epoxy resin fiberglass plate adopts five-layer composite layer structure, They are the first layer of epoxy resin, the second layer of glass fiber felt, the third layer of epoxy resin, the fourth layer of glass fiber felt and the fifth layer of epoxy resin, that is, continuous glass fiber through the prepreg process mold forming.

[0027] In the present embodiment, the method for using the composite material to prepare the automobile spare tire cover is as follows:

[0028] 1) Preparation of epoxy resin glass fiber board composite material: using prepreg process, the continuous glass fiber mat is impregnated with resin in advance, after compound cooling in the mold cavity, the spare semi-finished product is stored, and then the semi-finished material is stacked in t...

Embodiment 3

[0039] In this embodiment, the applicant has passed the static abuse test (distributed load test) and adopted the PHV1450-DV high and low temperature environmental test chamber to test the composite material of the present application under the load of 200 kg. The test results are as follows:

[0040] The test result of embodiment 3.1

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com