High-purity graphite powder and purification process thereof

A high-purity graphite powder, graphite powder technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problem of difficult removal of impurities, and achieve the effect of increasing reaction time and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

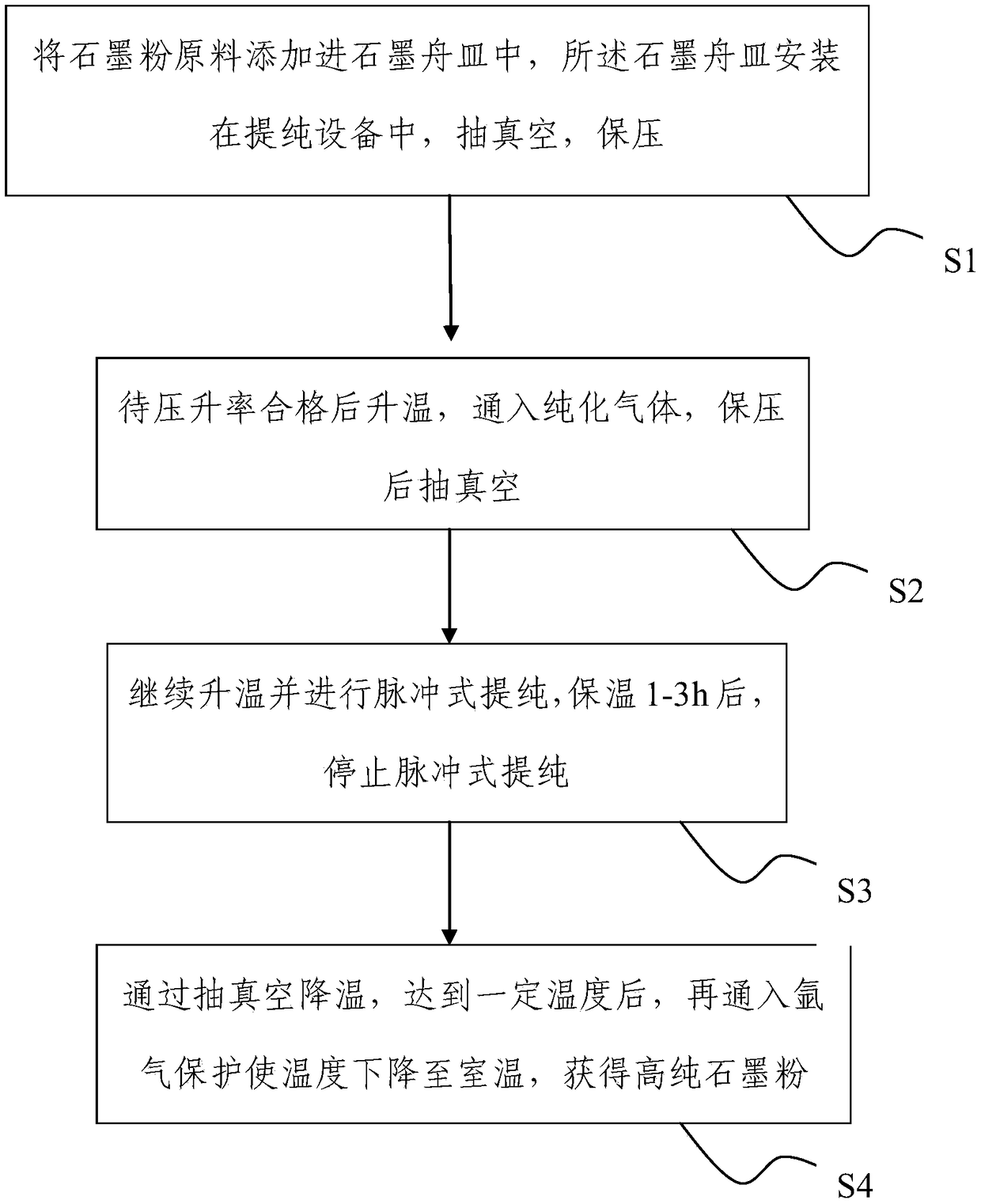

[0026] like figure 1 Shown, a kind of purification process of high-purity graphite powder comprises the steps:

[0027] S1. Add microcrystalline graphite with a particle size D50 of 0.2 to 0.5mm and a purity of 88% into a graphite boat with a size of 300×300×150mm, and put the loaded graphite boat into a cavity with a size of 600mm In the graphite purification equipment of ×600×900mm, vacuumize to -95KPa and hold the pressure for 1h;

[0028] S2. When the pressure rise rate is qualified and the temperature rises to 1600°C, start to feed CCl at the same time 4 and CHClF 2 , the flow rate is 100L / h, the absolute pressure value of the purified gas is 3KPa, and the vacuum is re-evacuated to the pressure -95KPa after holding the pressure for 0.5h;

[0029] S3. Raise the temperature to 2200°C at a heating rate of 1°C / min. During this period, carry out the purification operation in the pulse mode of vacuuming, filling purified gas, maintaining pressure and vacuuming again. After h...

Embodiment 2

[0033] A purification process for high-purity graphite powder, comprising the steps:

[0034] S1. Add flake graphite with a particle size D50 of 0.3-0.6mm and a purity of 88% into a graphite boat with a size of 300×300×150mm, and put the charged graphite boat into an inner cavity with a size of 600× In the 600×900mm graphite purification equipment, vacuumize to -98KPa, and hold the pressure for 1h;

[0035] S2. When the pressure rise rate is qualified and the temperature rises to 1550°C, start to feed CCl at the same time 4 and CHClF 2 , the flow rate is 300L / h, the absolute pressure value of the purified gas is 5KPa, and the vacuum is re-evacuated to the pressure of -98KPa after holding the pressure for 1h;

[0036] S3. Raise the temperature to 2250°C at a heating rate of 3°C / min. During this period, perform the purification operation in the pulse mode of vacuuming, filling purified gas, holding pressure and vacuumizing again. After holding at 2250°C for 3 hours, stop the p...

Embodiment 3

[0040] S1. Add needle-shaped petroleum coke with a particle size D50 of 0.3 to 0.8mm and a purity of 88% into a graphite boat with a size of 300×300×150mm, and put the charged graphite boat into an inner cavity with a size of In the graphite purification equipment of 600×600×900mm, vacuumize to -96KPa and keep the pressure for 1h;

[0041] S2. When the pressure rise rate is qualified and the temperature rises to 1700°C, start to feed CCl at the same time 4 and CHClF 2 , the flow rate is 200L / h, the absolute pressure value of the purified gas is 4KPa, and the vacuum is re-evacuated to the pressure of -96KPa after holding the pressure for 0.8h;

[0042] S3. Raise the temperature to 2350°C at a heating rate of 2°C / min. During this period, perform the purification operation in the pulse mode of vacuuming, filling purified gas, maintaining pressure and vacuuming again. After holding at 2350°C for 3 hours, stop the pulse type purification operation ;

[0043] S4. When the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com