Method for deep denitrification and dephosphorization of sewage

A technology for deep denitrification and sewage, applied in chemical instruments and methods, biological water/sewage treatment, oxidized water/sewage treatment, etc. , The effect of reducing COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

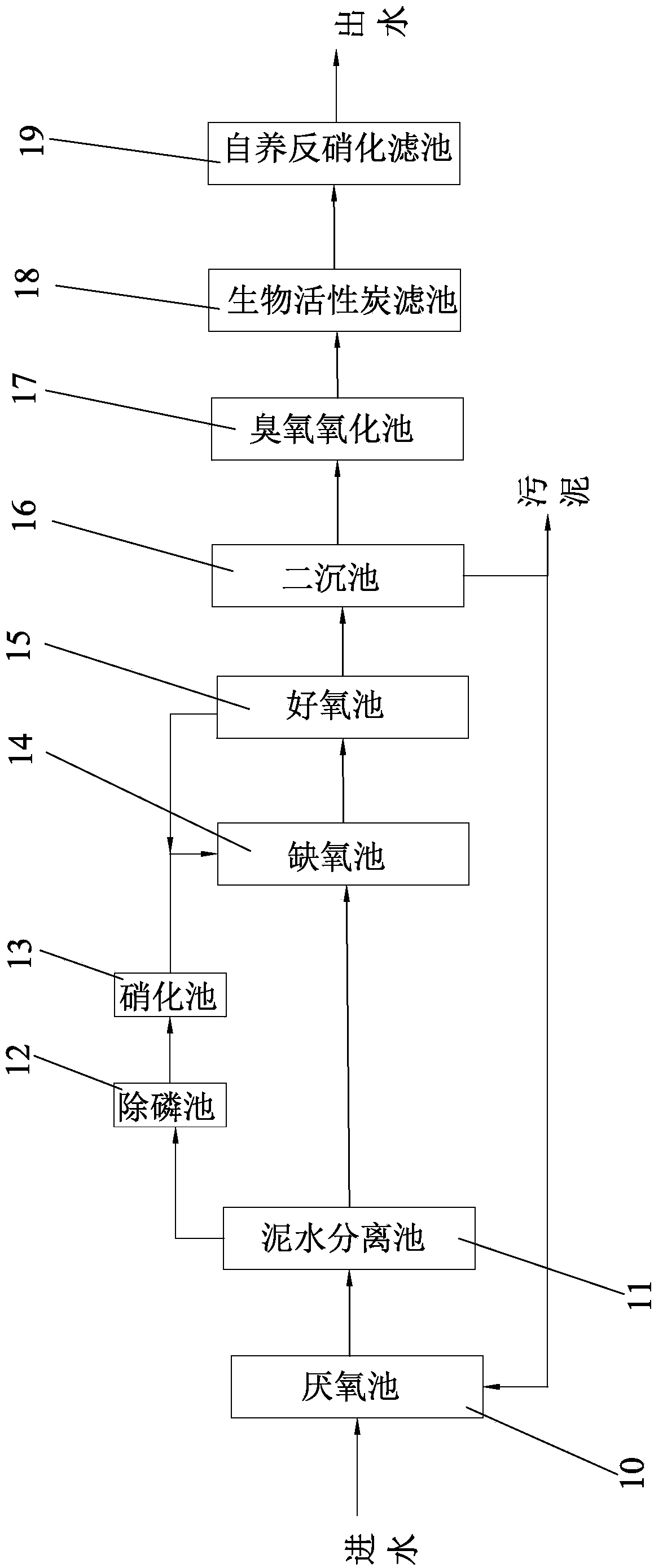

Embodiment 1

[0043] The sewage is taken from the sewage treatment pilot base of Jinlian Road, Pingshan District, Shenzhen City. The sewage flows into the anaerobic tank through the water inlet. After being treated in the anaerobic tank, the effluent flows into the mud-water separation tank. After being treated in the phosphorus removal tank, it flows into the nitrification tank, after being treated in the nitrification tank, it flows into the anoxic tank, and the sludge separated from the mud-water separation tank flows into the anoxic tank. Finally, the effluent flows into the secondary settling tank, part of the sludge in the secondary settling tank flows into the anaerobic tank, and the remaining sludge is discharged from the sludge outlet, and the effluent from the secondary settling tank flows into the ozone oxidation tank. Activated carbon filter, after being treated by the biological activated carbon filter, the effluent flows into the autotrophic denitrification filter, and is disch...

Embodiment 2

[0049] The treatment method of this embodiment 2 is basically the same as that of embodiment 1, the difference is that in embodiment 2, spherical suspension filler is used as the filler of the nitrification tank, while in embodiment 1, braided fiber filler is used as the filler of the nitrification tank.

[0050] The monitoring data are as follows: the concentration of influent COD is 206-500mg / L, the concentration of influent TN is 30.0-38.0mg / L, the concentration of influent TP is 3.1-4.3mg / L, and the average concentration of effluent COD is 5.0mg / L, the average concentration of TN in the effluent is 1.5mg / L, and the average concentration of TP in the effluent is lower than 0.1mg / L, which is better than the Class IV standard for surface water.

Embodiment 3

[0052] The treatment method of this embodiment 3 is basically the same as that of embodiment 1, the difference is that the nitrification tank does not use fillers in embodiment 3, but braided fiber filler is used as the filler of the nitrification tank in embodiment 1.

[0053] The monitoring data are as follows: the concentration of influent COD is 206-500mg / L, the concentration of influent TN is 30.0-38.0mg / L, the concentration of influent TP is 3.1-4.3mg / L, and the average concentration of effluent COD is 5.6mg / L, the average concentration of TN in the effluent is 1.8mg / L, and the average concentration of TP in the effluent is lower than 0.1mg / L, which is better than the Class IV standard for surface water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com