Concrete, and preparation method thereof

A technology of concrete and parts by weight, applied in the field of building materials, can solve the problems of poor workability and fluidity of concrete, affecting the strength and durability of concrete, medium sand, crushed stone, and aggregate subsidence, etc., so as to improve the compactness. , The effect of less stratified segregation and bleeding, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

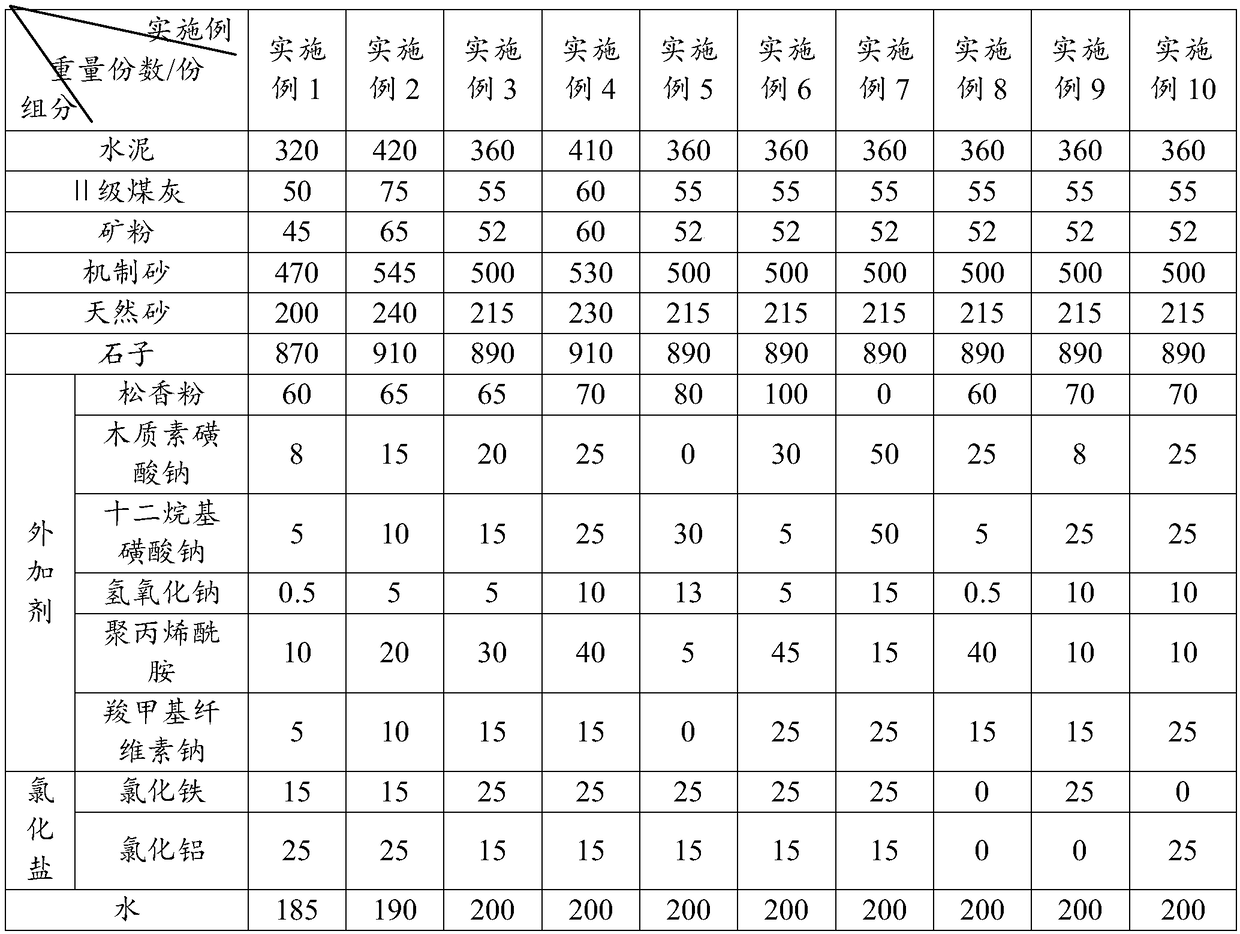

[0063] Embodiment 1: Concrete, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0064] Step 1, weighing cement, machine-made sand, natural sand, and stones according to the ratio of parts by weight and uniformly mixing to form the first mixture;

[0065] Step 2, weighing the second grade coal ash, mineral powder, ferric chloride, aluminum chloride according to the weight ratio, adding to the first mixture obtained in step 1, and mixing uniformly to form the second mixture;

[0066] Step 3, taking rosin powder, sodium lignosulfonate, sodium dodecylsulfonate, sodium hydroxide, polyacrylamide, and sodium carboxymethyl cellulose according to the ratio of parts by weight, and mixing them uniformly to form an admixture;

[0067] In step 4, water is weighed according to the ratio of parts by weight, and the admixture obtained in step 3 and water are sequentially added to the second mixture obtained i...

Embodiment 2-10

[0071] Examples 2-10: Concrete, the difference from Example 1 is that the raw material components and parts by weight included are as shown in Table 1.

Embodiment 11

[0072] Embodiment 11: Concrete, the difference from Embodiment 1 is that the particle size of Class II coal ash is 100-140 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com