COFs film material with ultra-low dielectric constant

An ultra-low dielectric constant, thin-film material technology, applied in the field of dielectric materials, to achieve the effects of good humidity resistance, simple operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

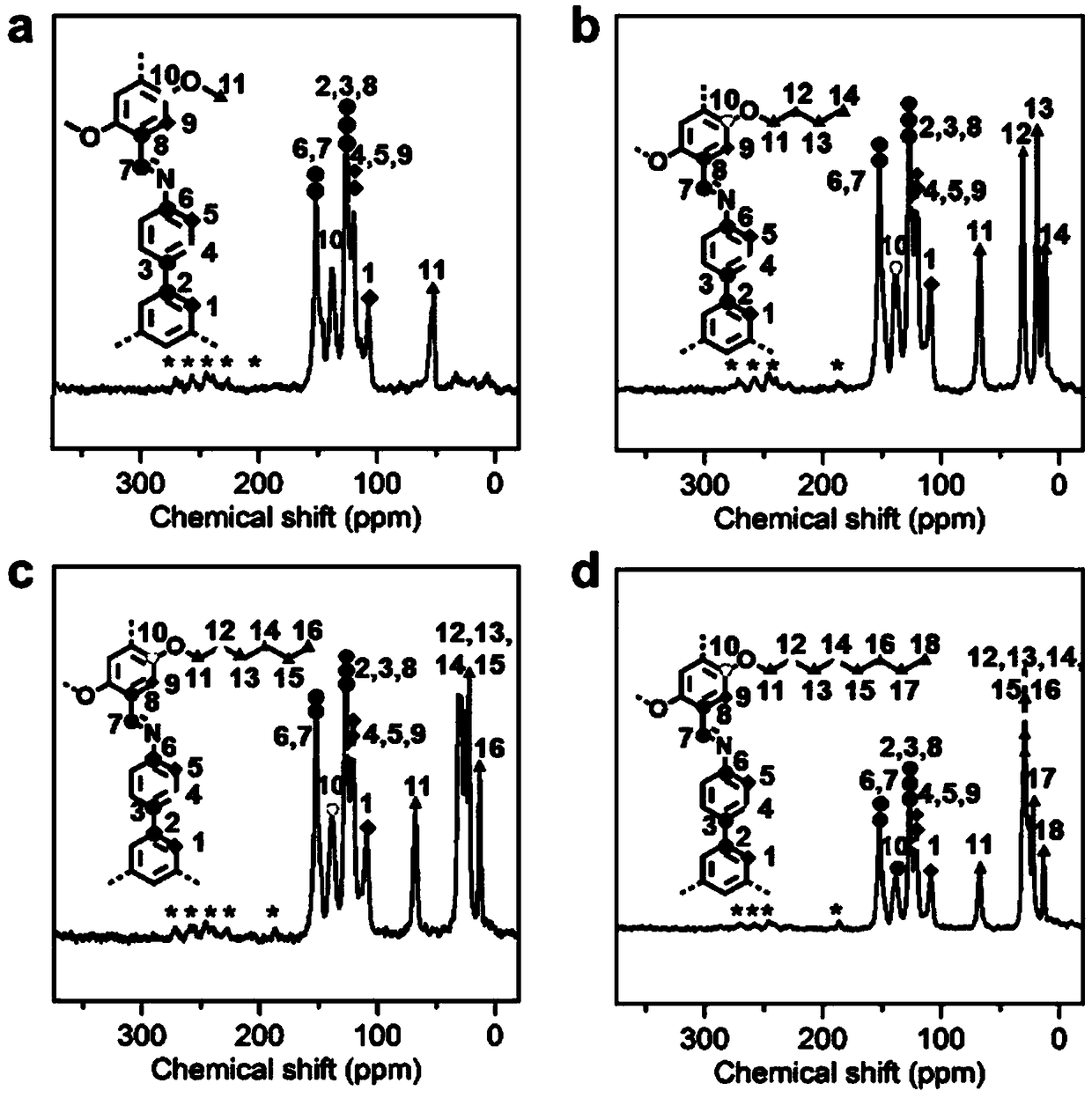

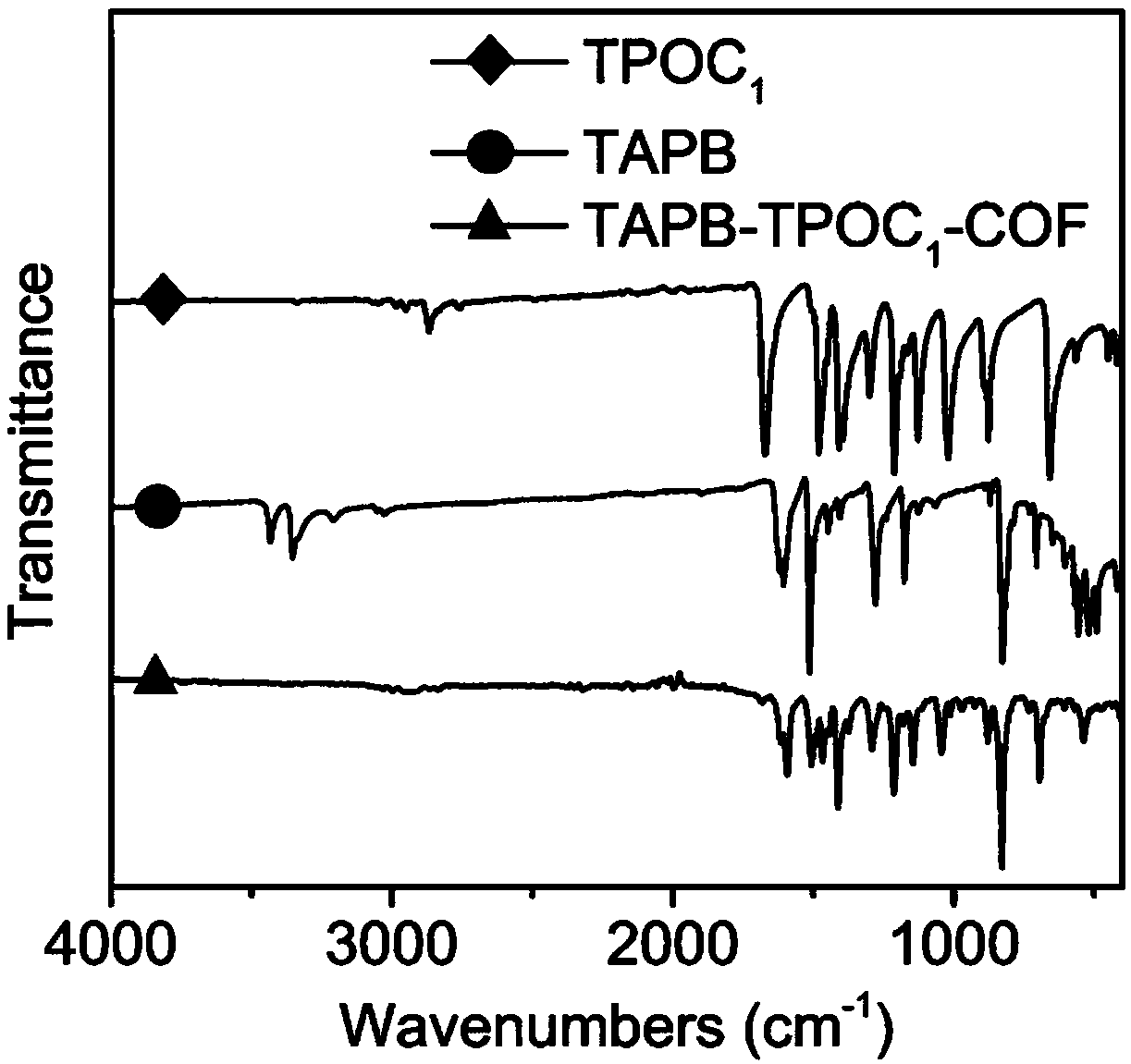

Embodiment 1

[0068] (1) Add TAPB and PTSA to a container filled with water and acetonitrile (V 水 :V 乙腈 =7:3) in a beaker, mix well to obtain a TAPB concentration of 2.67μM mL -1 , PTSA concentration is 8μM mL -1 Solution A; the TPOC 1 Add to a beaker filled with ethyl acetate, mix well to get TPOC 1 Concentration is 4μM mL -1 Solution B of

[0069] (2) Slowly transfer solution B to the upper layer of solution A, and seal the beaker containing solution B and solution A with a plastic wrap, and place it at 20° C. for 3 d to form a film material;

[0070] (3) Remove the film material from the beaker, soak and wash in water, N,N-dimethylformamide, ethanol, and acetone in sequence, soak and wash in each solvent for 3 times, and soak and wash for 1 hour each time; The washed film material was dried in an oven at 60°C for 12 hours to obtain a yellow COFs film material with ultra-low dielectric constant, which is called TAPB-TPOC for short. 1 - COF membrane material.

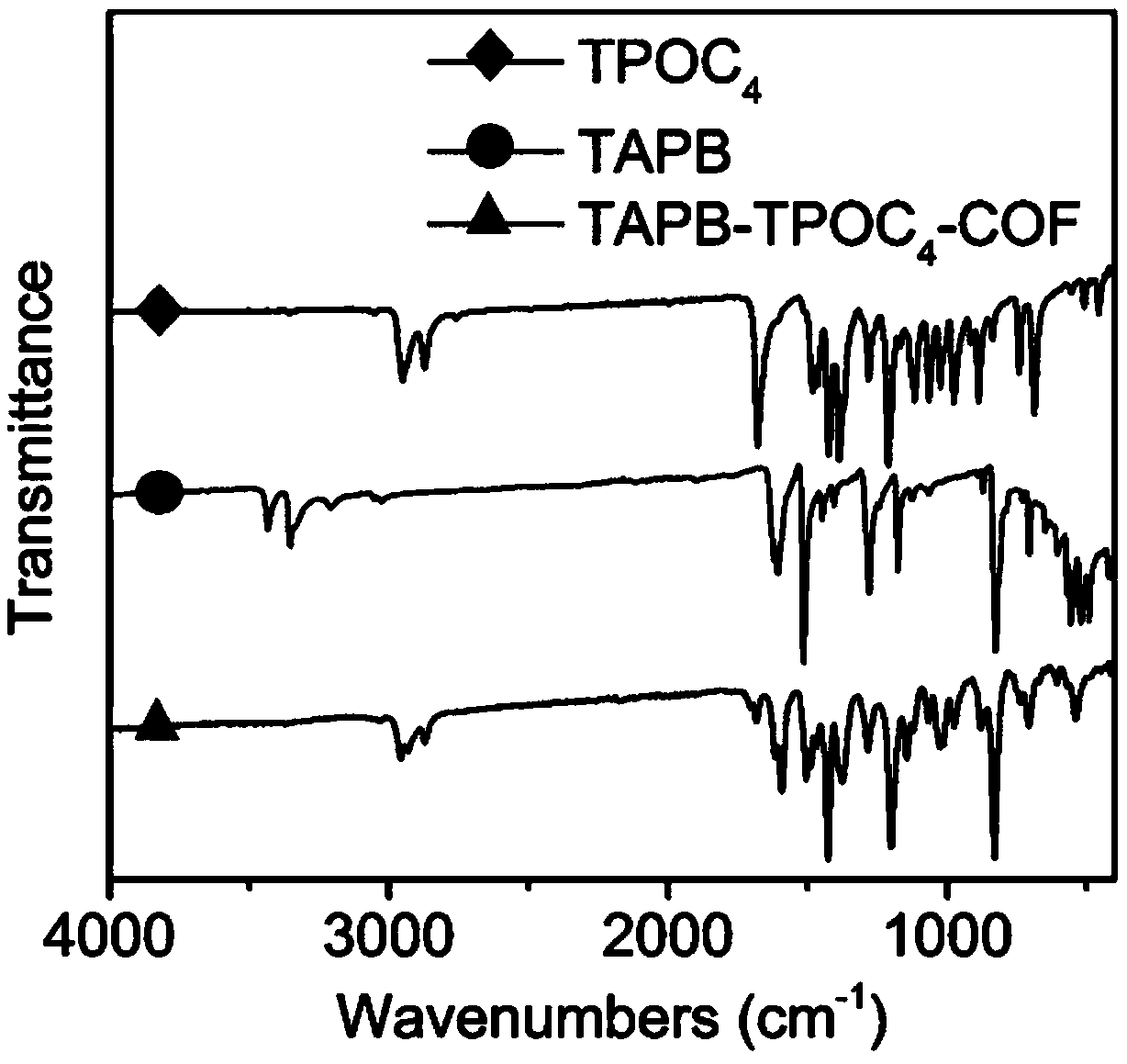

Embodiment 2

[0072] (1) Add TAPB and PTSA to a container filled with water and acetonitrile (V 水 :V 乙腈 =7:3) in a beaker, mix well to obtain a TAPB concentration of 4 μM mL-1 , PTSA concentration is 12μM mL -1 Solution A; the TPOC 4 Add to a beaker filled with ethyl acetate, mix well to get TPOC 4 Concentration is 6μM mL -1 Solution B of

[0073] (2) Slowly transfer solution B to the upper layer of solution A, and seal the beaker containing solution B and solution A with a plastic wrap, and place it at 20° C. for 3 d to form a film material;

[0074] (3) Remove the film material from the beaker, soak and wash in water, N,N-dimethylformamide, ethanol, and acetone in sequence, soak and wash in each solvent for 3 times, and soak and wash for 1 hour each time; The washed film material was dried in an oven at 60°C for 12 hours to obtain a yellow COFs film material with ultra-low dielectric constant, which is called TAPB-TPOC for short. 4 - COF membrane material.

Embodiment 3

[0076] (1) Add TAPB and PTSA to a container filled with water and acetonitrile (V 水 :V 乙腈 =7:3) in a beaker, mix well to obtain a TAPB concentration of 4 μM mL -1 , PTSA concentration is 12μM mL -1 Solution A; the TPOC 6 Add to a beaker filled with ethyl acetate, mix well to get TPOC 6 Concentration is 6μM mL -1 Solution B of

[0077] (2) Slowly transfer solution B to the upper layer of solution A, and seal the beaker containing solution B and solution A with a plastic wrap, and place it at 20° C. for 3 d to form a film material;

[0078] (3) Remove the film material from the beaker, soak and wash in water, N,N-dimethylformamide, ethanol, and acetone in sequence, soak and wash in each solvent for 3 times, and soak and wash for 1 hour each time; The washed film material was dried in an oven at 60°C for 12 hours to obtain a yellow COFs film material with ultra-low dielectric constant, which is called TAPB-TPOC for short. 6 - COF membrane material.

[0079] On the basis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com