Rubber filled compound for conductive shoes, preparation method and application thereof

A conductive shoe and rubber technology, which is applied in applications, footwear, clothing, etc., can solve the problems of high resistance, cannot meet the special wearing needs of consumers, and has no conductive function, and achieves simple preparation methods, good use effects, and high resistance. The effect of value stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

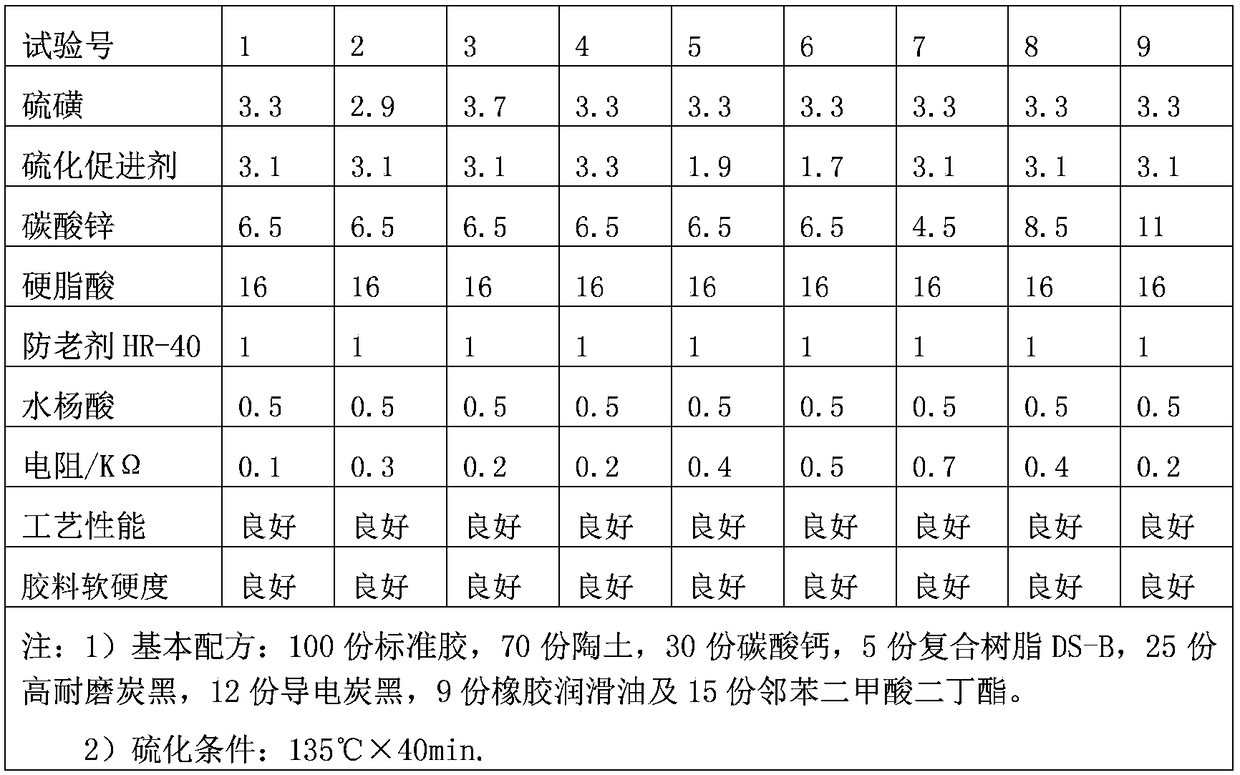

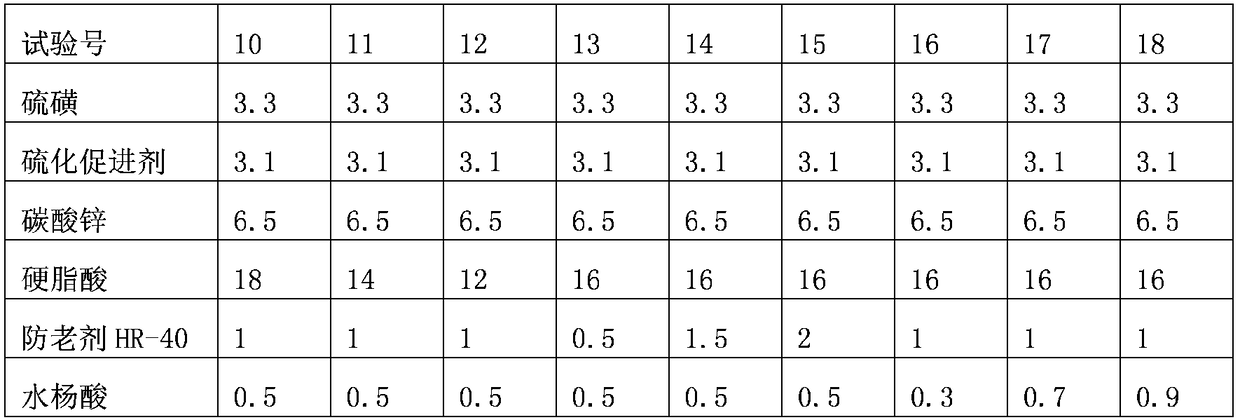

[0035] Embodiment 1 of the present invention: rubber core compound for conductive shoes, calculated in parts by weight, including 100 parts of standard glue, 3.3 parts of sulfur, 0.8 part of accelerator M, 1.6 parts of accelerator DM, 0.4 part of accelerator D, 0.3 parts of accelerator TMTD, 6.5 parts of zinc carbonate, 16 parts of stearic acid (three grades), 1 part of anti-aging agent HR-40, 70 parts of clay, 30 parts of calcium carbonate, 5 parts of composite resin DS-B, 0.5 parts of salicylic acid Acid, 25 parts of high wear-resistant carbon black, 12 parts of conductive carbon black, 9 parts of rubber lubricating oil and 15 parts of dibutyl phthalate.

[0036] The preparation method of rubber core compound for conductive shoes, each component is taken according to the above weight fraction, 1) Preparation of plasticized rubber: 100 parts of 1# standard rubber is pressed in a mixer at 120-130 ° C for 6 Minutes, discharge to the open rubber mixer, wrap the roll, and weigh t...

Embodiment 2

[0038] Embodiment 2 of the present invention: rubber core compound for conductive shoes, calculated in parts by weight, including 100 parts of standard glue, 3.3 parts of sulfur, 0.8 part of accelerator M, 1.6 parts of accelerator DM, 0.4 part of accelerator D, 0.3 parts of accelerator TMTD, 6.5 parts of zinc carbonate, 18 parts of stearic acid (three grades), 1 part of anti-aging agent HR-40, 80 parts of clay, 20 parts of calcium carbonate, 5 parts of composite resin DS-B, 0.5 parts of salicylic acid Acid, 25 parts of high wear-resistant carbon black, 12 parts of conductive carbon black, 9 parts of rubber lubricating oil and 15 parts of dibutyl phthalate.

[0039] The preparation method and application are the same as claim 1.

Embodiment 3

[0040] Embodiment 3 of the present invention: rubber core compound for conductive shoes, calculated in parts by weight, including 100 parts of standard glue, 3.3 parts of sulfur, 0.8 part of accelerator M, 1.6 parts of accelerator DM, 0.4 part of accelerator D, 0.3 parts of accelerator TMTD, 6.5 parts of zinc carbonate, 16 parts of stearic acid (three grades), 1 part of anti-aging agent HR-40, 70 parts of clay, 30 parts of calcium carbonate, 5 parts of composite resin DS-B, 0.5 parts of salicylic acid Acid, 30 parts of high wear-resistant carbon black, 8 parts of conductive carbon black, 9 parts of rubber lubricating oil and 17 parts of dibutyl phthalate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com