Polymeric environmentally-friendly root puncture-resistant waterproof polyurethane coating for planting roof

A waterproof coating and polymer technology, applied in the field of coatings, to achieve the effects of excellent weather resistance, excellent physical and mechanical properties, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] By weight, add 15 parts of polyether 2000N, 10 parts of polyether 330N, 0.2 parts of dispersant, 0.2 part of defoamer, 20 parts of talcum powder, 5 parts of kaolin, 15 parts of heavy calcium, and 5 parts of nano-TiO2 into the closed reaction kettle, Mixing and heating by high-speed stirring, dehydration under reduced pressure at 120°C 0.06Mpa for 180min, so that the moisture content of the material in the reactor is ≤0.02%, lower the temperature to 75°C-80°C, add 4 parts of MDI, and react at a constant temperature at 80°C 120min, add 0.06 part of catalyst, react for 60min, stop the reaction, add 1.2 parts of root inhibitor, 1 part of latent curing agent, 0.2 part of antioxidant, 1 part of anti-sedimentation agent under high-speed stirring after the reaction, keep stirring for 60 minutes , and finally lowered to below 40°C for discharge.

Embodiment 2

[0026] Add 20 parts of polyether 2000N, 10 parts of polyether 330N, 0.5 parts of dispersant, 0.5 parts of defoamer, 22 parts of talc, 6 parts of kaolin, 16 parts of heavy calcium, and 7 parts of nano-TiO2 into the closed reaction kettle, and pass Stir, mix and heat, dehydrate under reduced pressure at 120°C 0.06Mpa for 180min, make the moisture content of the material in the reactor ≤0.02%, cool down to 75°C-80°C, add 6 parts of MDI and react at constant temperature for 120min at 80°C, add 0.1 part of catalyst, after reacting for 60 minutes, stop the reaction, add 0.8 parts of root inhibitor, 1.5 parts of latent curing agent, 0.5 parts of antioxidant, 2 parts of anti-settling agent under high-speed stirring after the reaction, keep stirring for 60 minutes, and finally drop Discharge below 40°C.

[0027] The construction process is as follows:

[0028] Grassroots treatment --- brushing the primary treatment agent --- additional layer construction of weak parts --- brushing the...

PUM

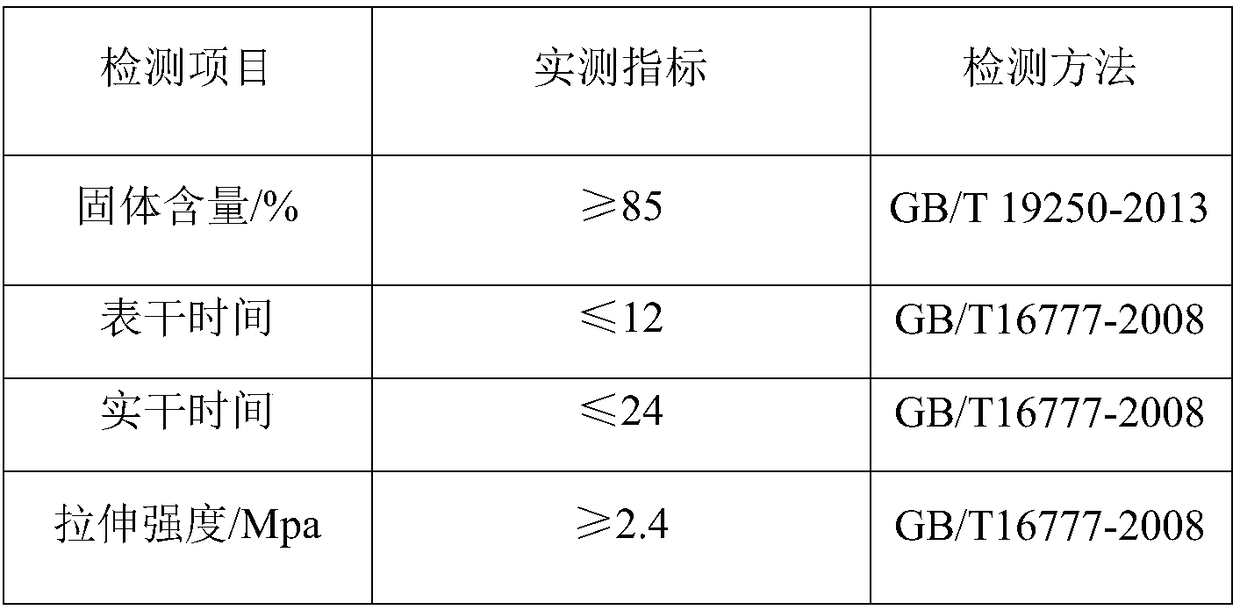

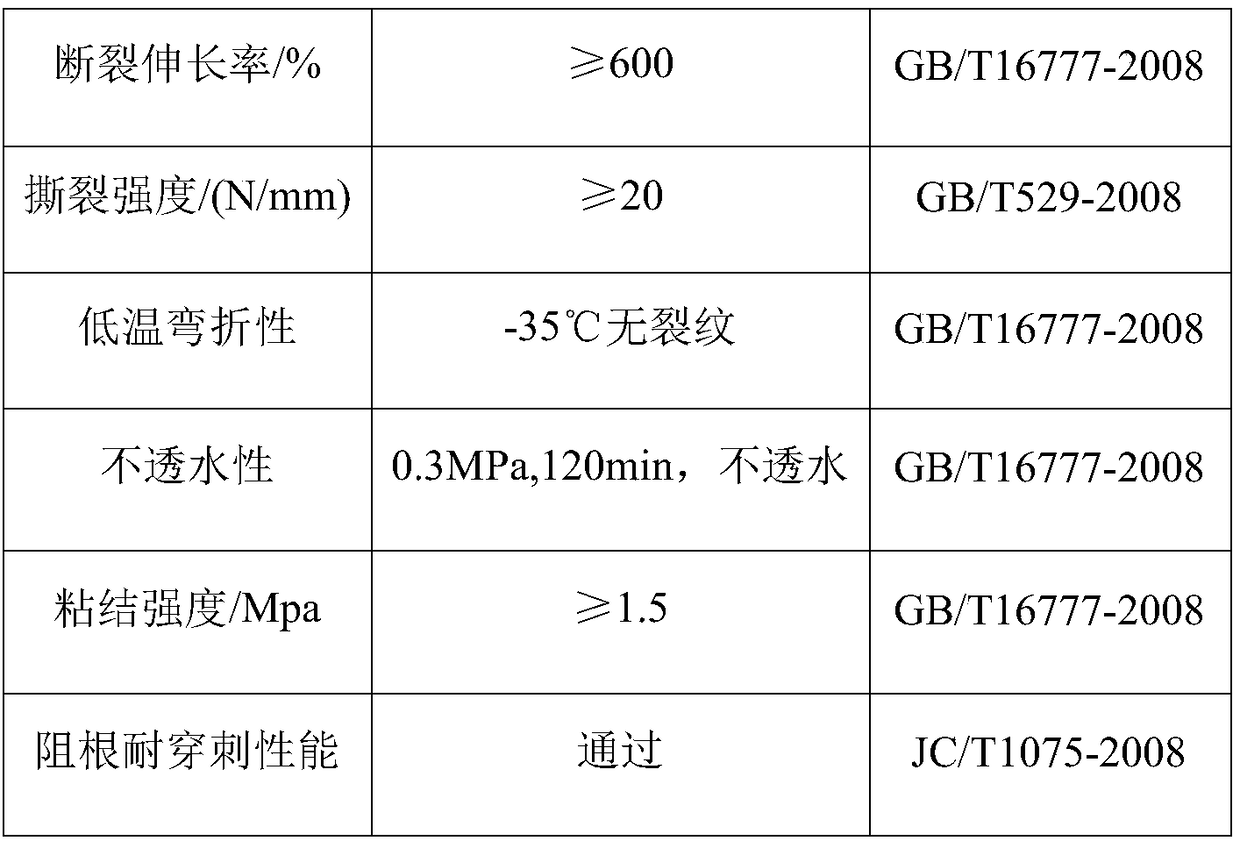

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com