High-performance narrowband fluorescent powder and preparation method thereof

A fluorescent powder, high-performance technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of low external quantum efficiency and instability of red fluorescent powder, achieve low cost, improve moisture resistance, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0041] This example provides Cs 2 SiF 6 : Mn 4+ The fluorescent powder is prepared by the following preparation method.

[0042] (1)K 2 MnF 6 preparation of

[0043] Prepare K according to the method described in the document Angew. Chem-Ger. Edit. 65, 304-304 (1953) 2 MnF 6 crystals.

[0044] 0.45 g KMnO 4 and 9 g KHF 2 Dissolve in 30 ml of hydrofluoric acid (49 %), stir for 30 minutes, then gradually drop into about 1.2 ml of hydrogen peroxide (30 wt. %), gradually form a yellow precipitate in the solution, filter the solution to obtain the precipitate, and use acetone After cleaning, bake at 80°C for 2 hours to get K 2 MnF 6 .

[0045] Each example uses K 2 MnF 6 As the manganese source, other manganese sources, such as cesium hexafluoromanganate, also have the same effect.

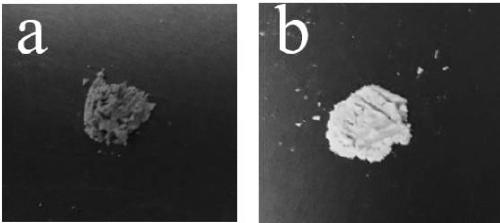

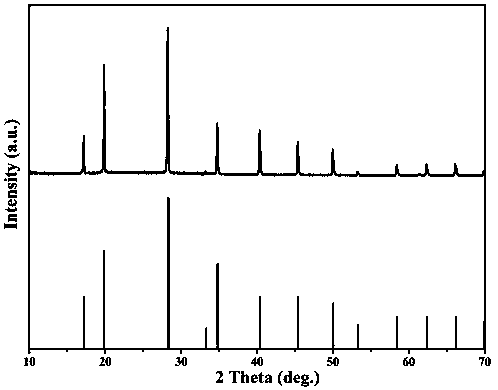

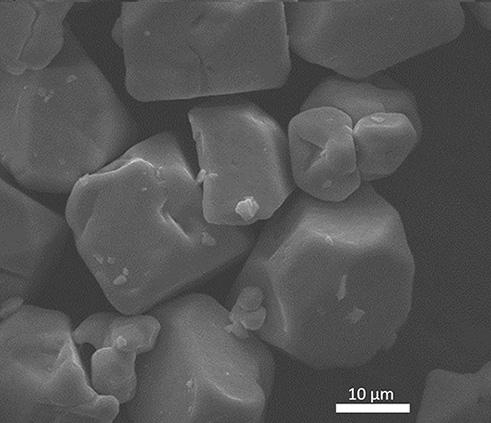

[0046] (2) Cs before passivation 2 SiF 6 : Mn 4+ Phosphor powder preparation

[0047] A certain amount of potassium hexafluoromanganate (K 2 MnF 6 ) was dissolved in 6.5 ml HF (40 ...

Embodiment 5

[0054] Example 5 is consistent with Example 3 except that the silicon-containing compound selected is ethyl orthosilicate (0.5208 g). The prepared Cs 2 SiF 6 :Mn 4+ The performance of phosphor powder is similar to that of Example 3.

Embodiment 6

[0055] Example 6 is consistent with Example 3 except that the selected cesium-containing compound is cesium hydroxide (0.3748g). The prepared Cs 2 SiF 6 :Mn 4+ The performance of phosphor powder is similar to that of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com