Nickel-containing high-toughness controllable degradation magnesium alloy material as well as preparation method and application thereof

A magnesium alloy, high-strength technology, applied in the field of nickel-containing high-strength toughness controllable degradable magnesium alloy materials and its preparation, can solve the problems of increased construction period and cost, difficult backflow of fragments, difficult drilling and milling, etc., to improve construction efficiency , Eliminate the drilling and grinding recovery process and reduce the difficulty of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

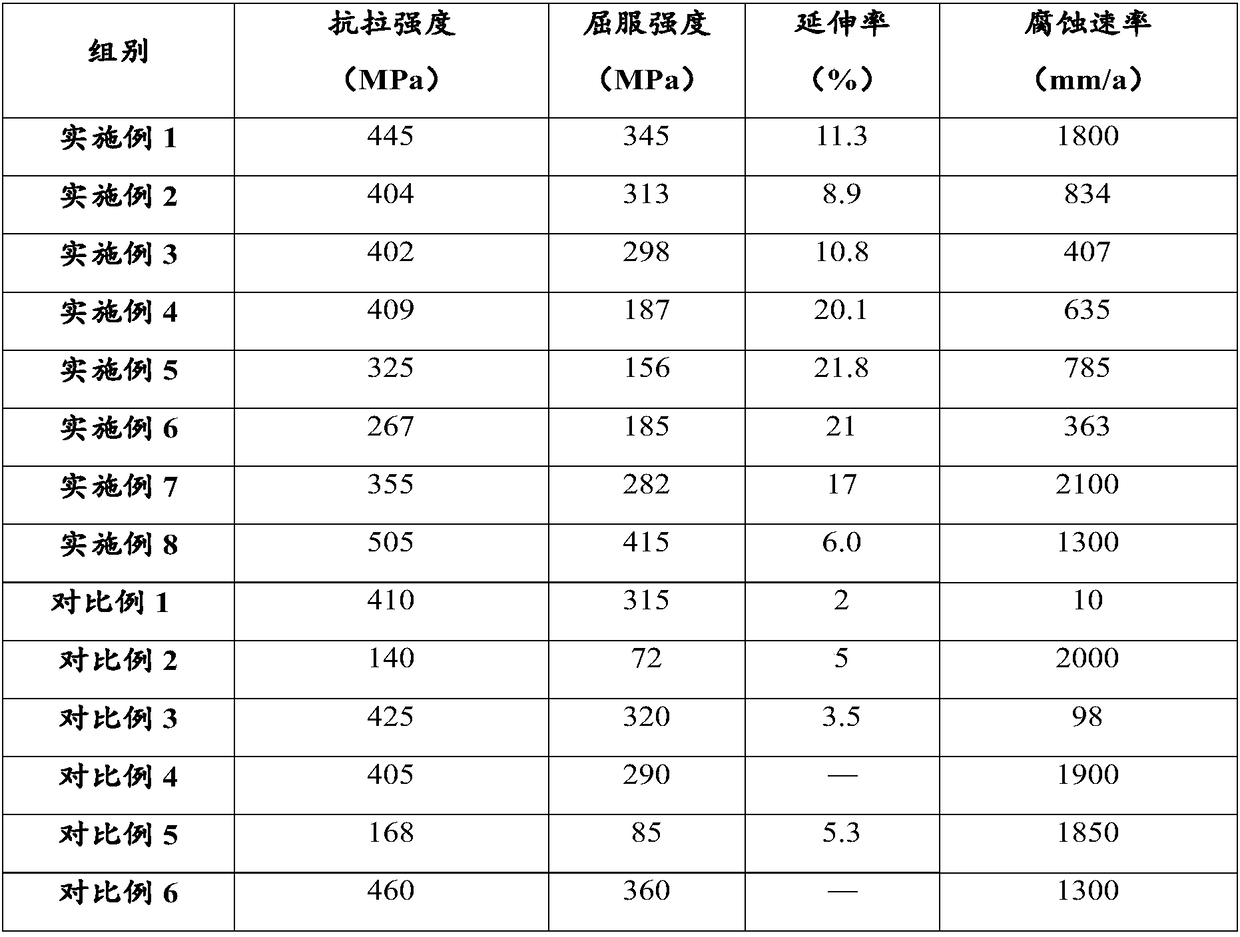

Examples

preparation example Construction

[0067] According to the second aspect of the present invention, the present invention provides a method for preparing the above-mentioned nickel-containing high-strength toughness controllable degradation magnesium alloy material, comprising the following steps:

[0068] The nickel source, the magnesium source and the rare earth source are uniformly mixed and alloyed to obtain a nickel-containing high-strength toughness controllable degradation magnesium alloy material.

[0069] The preparation method of the nickel-containing high-strength toughness controllable degradable magnesium alloy material provided by the invention has simple process, convenient operation, easy industrialized large-scale production and low cost.

[0070] In a preferred embodiment of the present invention, the alloying treatment includes a melting casting method and a powder alloying method.

[0071] In a preferred embodiment of the present invention, the nickel source is selected from simple nickel and...

Embodiment 1

[0101] This embodiment provides a nickel-containing high-strength toughness controllable degradation magnesium alloy material, including the following components by mass percentage: Ni: 6.9%, Y: 18%, the balance is Mg and unavoidable impurities; wherein, Mg, Ni and Y form Mg 12 YNi type long period phase, Mg 5 Y phase and Mg 2 Ni phase, Mg 12 The volume fraction of YNi-type long-period phase is 66%, Mg 5 The volume fraction of Y phase is 4%, Mg 2 The volume fraction of the Ni phase is 2%.

[0102] The preparation method of the nickel-containing high-strength toughness controllable degradation magnesium alloy material provided in this embodiment includes the following steps:

[0103] (1) Accurate batching according to the formula quantity; wherein, nickel source, yttrium source and magnesium source are added in the form of magnesium-yttrium alloy and nickel-yttrium alloy;

[0104] (2) Casting: use resistance furnace or power frequency induction furnace for melting, use ar...

Embodiment 2

[0107] This embodiment provides a nickel-containing high-strength and toughness controllable degradation magnesium alloy material, including the following components by mass percentage: Ni: 2.3%, Y: 5.3%, the balance is Mg and unavoidable impurities, the balance Mg and unavoidable impurities; among them, Mg, Ni and Y form Mg 12 YNi type long period phase, Mg 5 Y phase and Mg 2 Ni phase, Mg 12 The volume fraction of YNi-type long-period phase is 23%, Mg 5 The volume fraction of Y phase is 6%, Mg 2 The volume fraction of the Ni phase is 1.8%.

[0108]The preparation method of the degradable magnesium alloy material provided in this example is the same as that of Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com