Eye shadow and preparation method thereof

A technology of eye shadow and talcum powder, which is applied in the field of eye shadow and its preparation, can solve the problems of not being able to enhance the three-dimensional sense of the eye, prone to itching and pain in allergic skin, and poor durability of eye shadow, so as to achieve good smudging effect, Enhanced three-dimensional, easy-to-apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

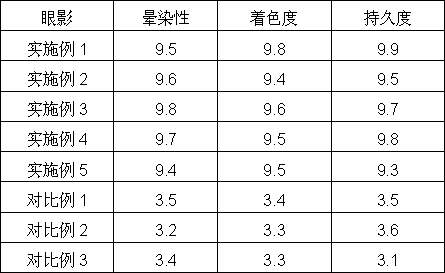

Examples

Embodiment 1

[0050] The raw material of the eye shadow of the present embodiment comprises following parts by weight:

[0051] 40 parts of talcum powder;

[0052] 6 parts mica powder;

[0053] Lubricant 1-part;

[0054] 2 parts mineral oil;

[0055] 2 parts emollient;

[0056] 1 part diisostearyl malate;

[0057] 3 parts emulsifier;

[0058] Catalyst 2 parts;

[0059] 3 parts preservative;

[0060] 10 parts of inorganic pigments;

[0061] 10 parts of deionized water.

[0062] Among them, the surface treatment process of talc powder is as follows: first mix polydimethylsiloxane and absolute ethanol at a volume ratio of 10%, then add 200 mesh talc powder and stir for 5 minutes, send it into an oven and bake it at 60°C 1h, natural cooling.

[0063] Specifically, the mica powder has a particle size of 2 μm and a silicon dioxide content of 44.1%.

[0064] The lubricant is a mixture of magnesium stearate and petrolatum.

[0065] The emollient is isooctyl palmitate.

[0066] The emul...

Embodiment 2

[0075] The raw material of the eye shadow of the present embodiment comprises following parts by weight:

[0076] 60 parts of talcum powder;

[0077] 10 parts of mica powder;

[0078] 3 parts lubricant;

[0079] 5 parts of mineral oil;

[0080] Emollient 5 parts;

[0081] 4 parts of diisostearyl malate;

[0082] 5 parts of emulsifier;

[0083] 8 parts of catalyst;

[0084] 9 parts of preservatives;

[0085] 28 parts of inorganic pigments;

[0086] 20 parts of deionized water.

[0087] Among them, the surface treatment process of talc powder is as follows: first mix polydimethylsiloxane and absolute ethanol at a volume ratio of 15%, then add 300 mesh talc powder and stir for 8 minutes, then put it into an oven and bake it at 80°C 1.5h, natural cooling.

[0088] Specifically, the mica powder has a particle size of 4 μm and a silicon dioxide content of 45.6%.

[0089] The lubricant is polyethylene wax.

[0090]The emollient is hydrogenated polyisobutylene.

[0091] T...

Embodiment 3

[0100] The raw material of the eye shadow of the present embodiment comprises following parts by weight:

[0101] 45 parts of talcum powder;

[0102] 7 parts mica powder;

[0103] 2 parts lubricant;

[0104] 3 parts mineral oil;

[0105] 2 parts emollient;

[0106] 4 parts of diisostearyl malate;

[0107] 3 parts emulsifier;

[0108] 4 parts of catalyst;

[0109] 8 parts of preservatives;

[0110] 15 parts of inorganic pigments;

[0111] 15 parts of deionized water.

[0112] Among them, the surface treatment process of talc powder is as follows: first mix polydimethylsiloxane and absolute ethanol at a volume ratio of 12%, then add 230 mesh talc powder and stir for 6 minutes, then put it into an oven and bake it at 67°C 1h, natural cooling.

[0113] Specifically, the mica powder has a particle size of 3 μm and a silicon dioxide content of 45.0%.

[0114] The lubricant is magnesium stearate.

[0115] The emollient is isooctyl palmitate.

[0116] The emulsifier is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com