Pipeline spraying repair material, preparation method and construction process for repairing pipeline with pipeline spraying repair material

A repairing material and pipeline spraying technology, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of high risk of construction with water, difficult construction of pipeline repairs, unsatisfactory results, etc., and achieve improvement Mortar rheology, excellent mechanical properties and corrosion resistance, ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

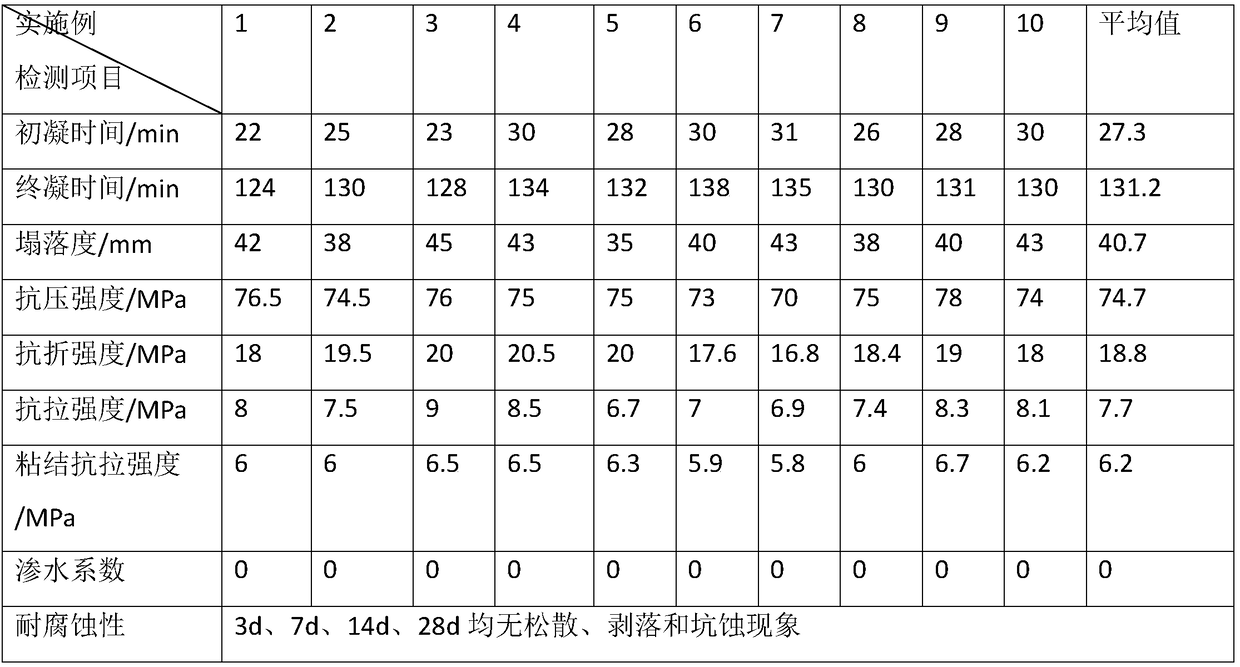

[0038] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

[0039] One aspect of the present invention provides a pipeline spraying repair material, which is composed of the following raw materials in parts by weight: 40-60 parts of cementitious material, 45-70 parts of aggregate, 3-9 parts of dispersible latex powder, fiber material 3-10 parts, 2-6 parts of water-retaining agent, 1-3.5 parts of accelerator, 2-6 parts of underwater curing agent, 0.4-1.2 parts of water reducing agent, stabilizer (can be 2,6-di-tert-butyl -4-methylphenol) 2-6 parts and water 25-35 parts.

[0040] Wherein, the cementitious material includes cement, fly ash and silica fume; wherein, the mass ratio of cement, fly ash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com