A coordinated control method for variable speed pumped-storage units based on working condition optimization

A pumped storage unit, coordinated control technology, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve problems such as the instability of the aggravation transition process, the influence of operation stability, and the disturbance of speed adjustment, etc., to achieve Achieve optimal efficiency control, improve operational stability, and achieve rapid control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below in conjunction with accompanying drawing, but the present invention is not limited to following embodiment, described method is conventional method unless otherwise specified, and described material all can be obtained from open commercial channel if not specified.

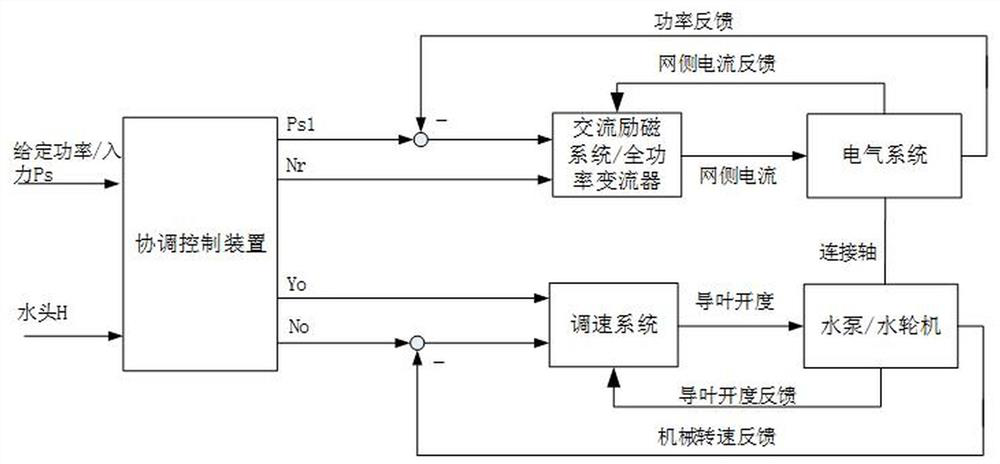

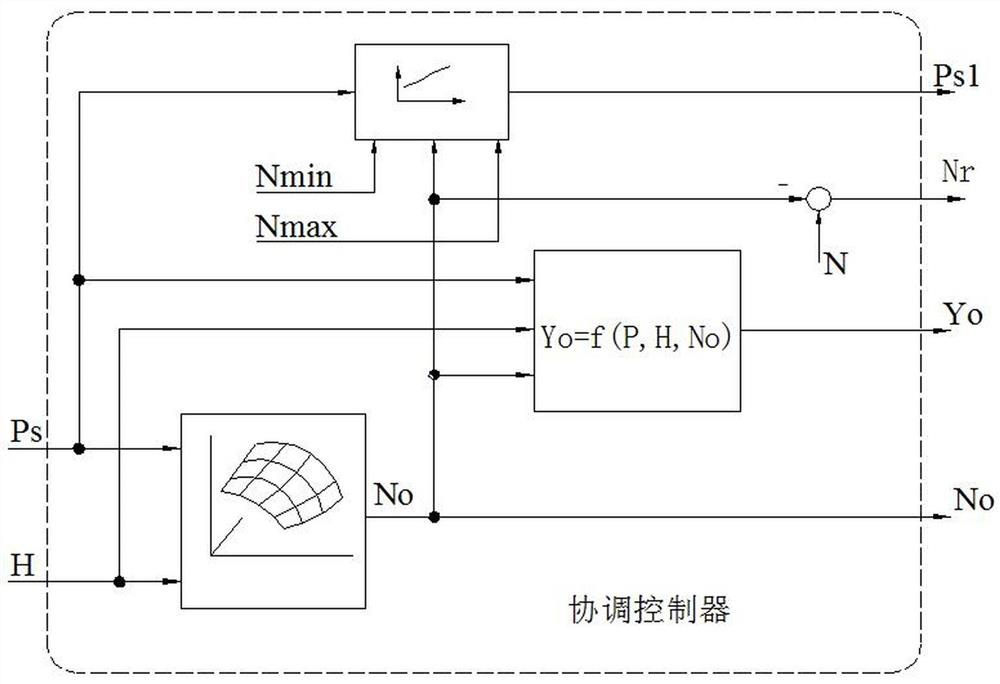

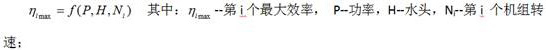

[0038] The coordinated control method of the variable-speed pumped-storage unit based on the optimization of working conditions in the present invention is based on fully grasping the characteristics of the variable-speed pump-turbine, fully considering the S characteristics of the pump-turbine and the characteristics of the reverse pump, and according to the different characteristics of the variable-speed unit Operating conditions, different operating points, different control strategies are adopted, and the AC excitation system and speed control system are coordinated at the same time to achieve efficient and stable operation of the variable speed unit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com