Enzymatic method for removing seed coats of walnut kernels in combination with infrared drying

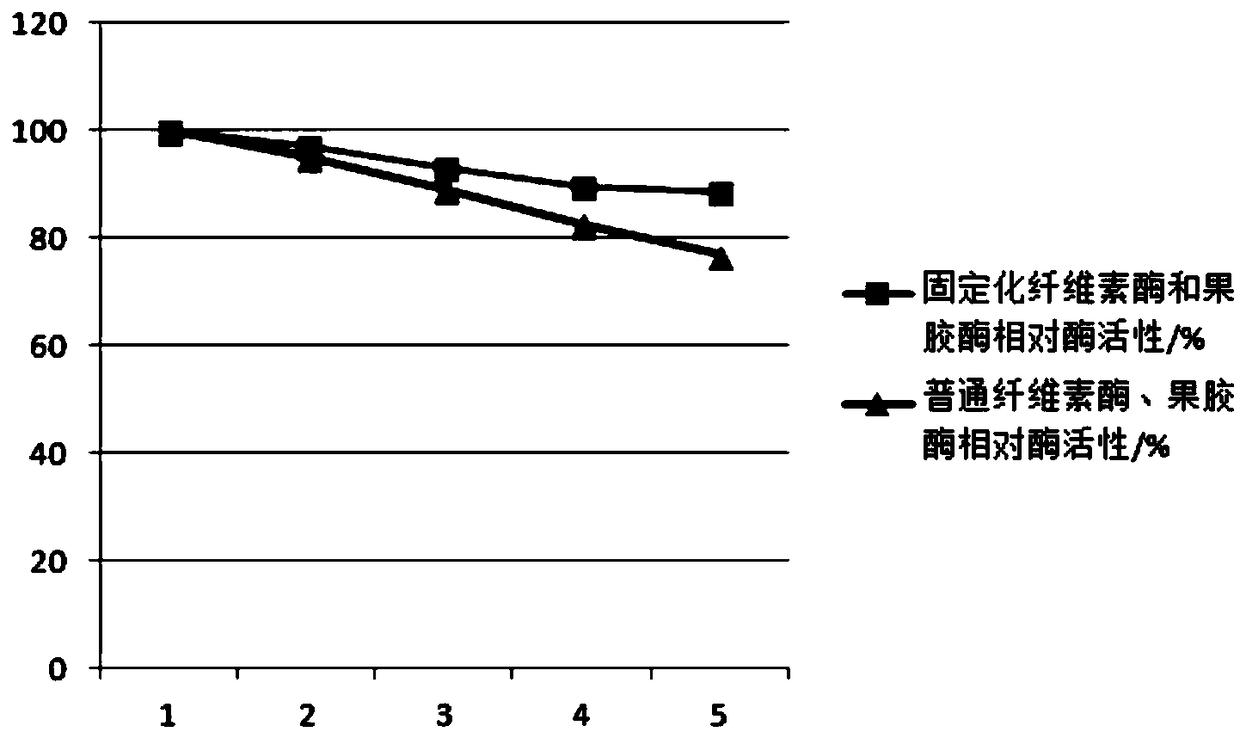

An infrared drying and walnut kernel technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems that the peeling effect of the compound enzymolysis solution is not optimal, affects the number of uses, and is difficult to reuse. The effect of peeling time, increasing the number of uses, prolonging the duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

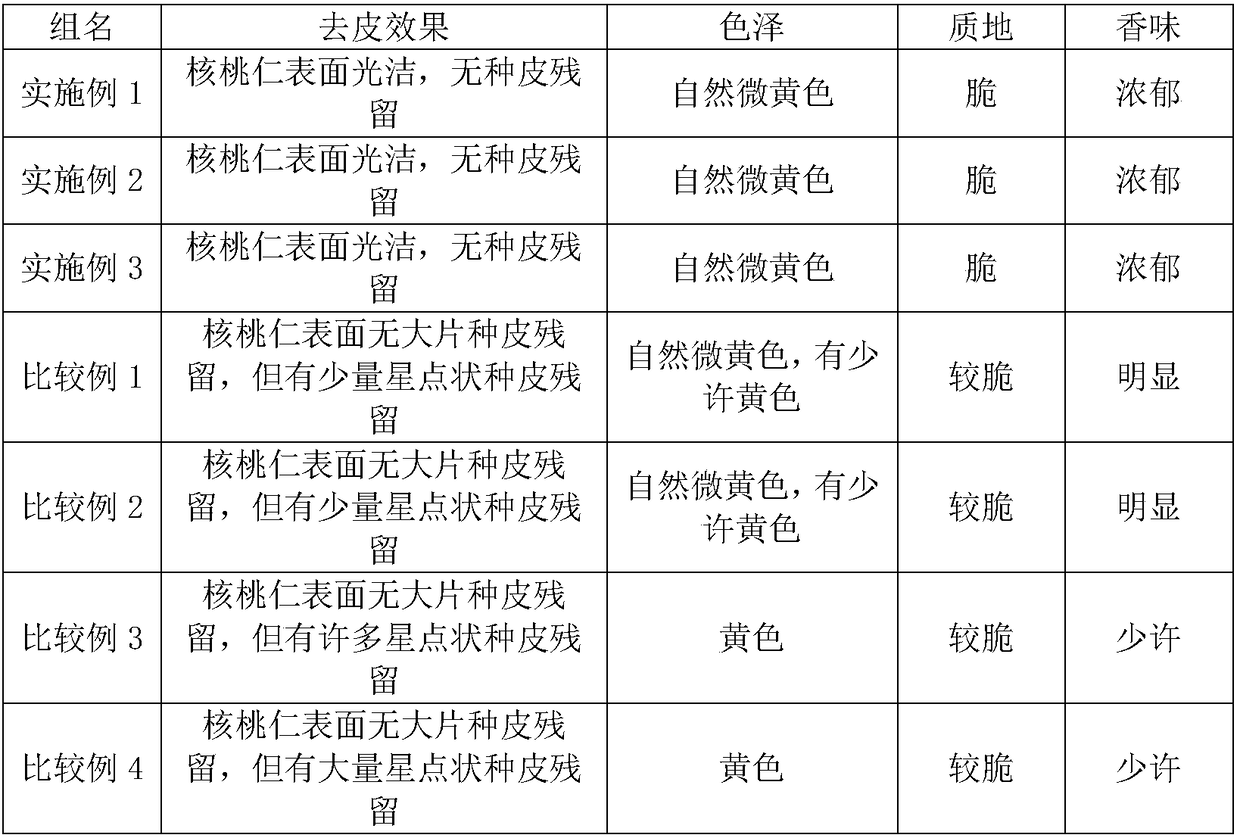

Embodiment 1

[0030] The enzymatic method of the present embodiment is combined with infrared drying to remove the method for walnut kernel seed coat, adopts the following steps:

[0031] S1. Wash the walnut kernels with seed coats, remove impurities and mildew, and set aside;

[0032] S2. Add the walnut kernels obtained in step S1 to the immobilized cellulase solution, adjust the pH value to 4.5, and make the enzyme activity of the immobilized cellulase 50000U / g, heat it at 45°C for 3 hours, filter and set aside ;

[0033] S3. Add the walnut kernels obtained in step S2 to the protease solution, adjust the pH value to 6.5, and make the protease activity 100000U / g, heat-preserve and enzymolyze at 60°C for 5 hours, filter and set aside;

[0034] S4, remove the walnut kernels obtained in step S3 and perform ultrasonic rinsing, the rinsing temperature is 65°C, the ultrasonic frequency is 30kHz, filter the skin and drain the surface moisture of the walnut kernels;

[0035] S5. Put the walnut k...

Embodiment 2

[0038] The enzymatic method of the present embodiment is combined with infrared drying to remove the method for walnut kernel seed coat, adopts the following steps:

[0039] S1. Wash the walnut kernels with seed coats, remove impurities and mildew, and set aside;

[0040] S2. Add the walnut kernels obtained in step S1 to the immobilized cellulase solution, adjust the pH value to 4.5, and make the enzyme activity of the immobilized cellulase 50,000 U / g, keep the enzymolysis at 40°C for 3 hours, filter and set aside ;

[0041] S3. Add the walnut kernels obtained in step S2 to the protease solution, adjust the pH value to 6.5, and make the protease activity 100000U / g, keep it at 55°C for 5 hours, filter and set aside;

[0042] S4, remove the walnut kernels obtained in step S3 and perform ultrasonic rinsing, the rinsing temperature is 65°C, the ultrasonic frequency is 30kHz, filter the skin and drain the surface moisture of the walnut kernels;

[0043] S5. Put the walnut kernel ...

Embodiment 3

[0046] The enzymatic method of the present embodiment is combined with infrared drying to remove the method for walnut kernel seed coat, adopts the following steps:

[0047] S1. Wash, remove impurities, and remove mildew from the walnut kernels with seed coats, and set aside;

[0048] S2. Add the walnut kernels obtained in step S1 to the immobilized cellulase, adjust the pH value to 4.5, and make the enzyme activity of the immobilized cellulase 50000U / g, heat the enzymolysis at 50°C for 3 hours, filter and set aside;

[0049] S3. Add the walnut kernels obtained in step S2 to the protease solution, adjust the pH value to 6.5, and make the protease activity 100000U / g, heat the enzymolysis at 65°C for 5 hours, filter and set aside;

[0050] S4, remove the walnut kernels obtained in step S3 and perform ultrasonic rinsing, the rinsing temperature is 65°C, the ultrasonic frequency is 30kHz, filter the skin and drain the surface moisture of the walnut kernels;

[0051] S5. Put the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com