A kind of factory building fire prevention method

A plant and fire technology, applied in fire rescue, fire protection, construction, etc., can solve the problems of property loss expansion, poor fire prevention and fire extinguishing capabilities, etc., and achieve the effects of fire prevention, fire prevention performance improvement, and enhanced noise reduction and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

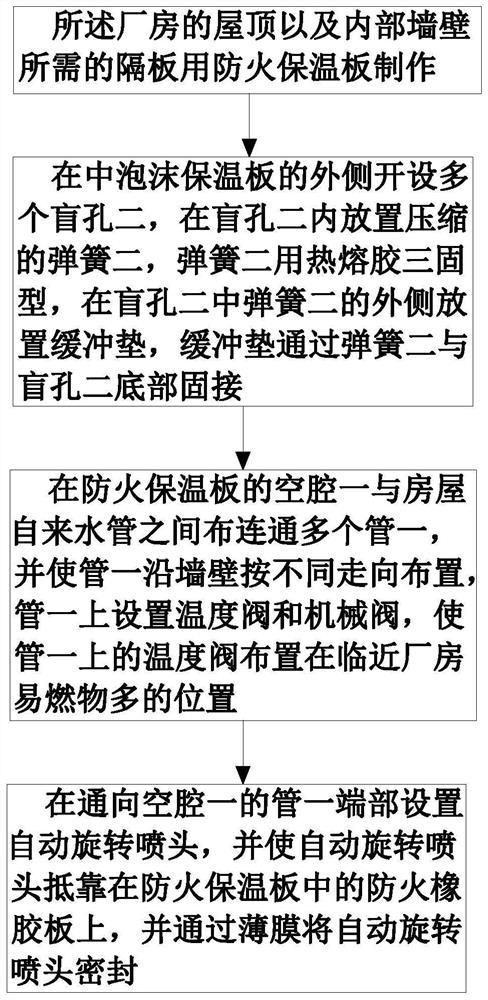

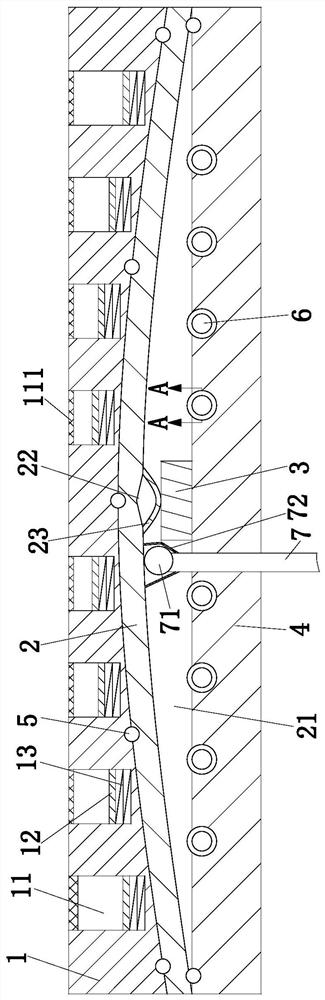

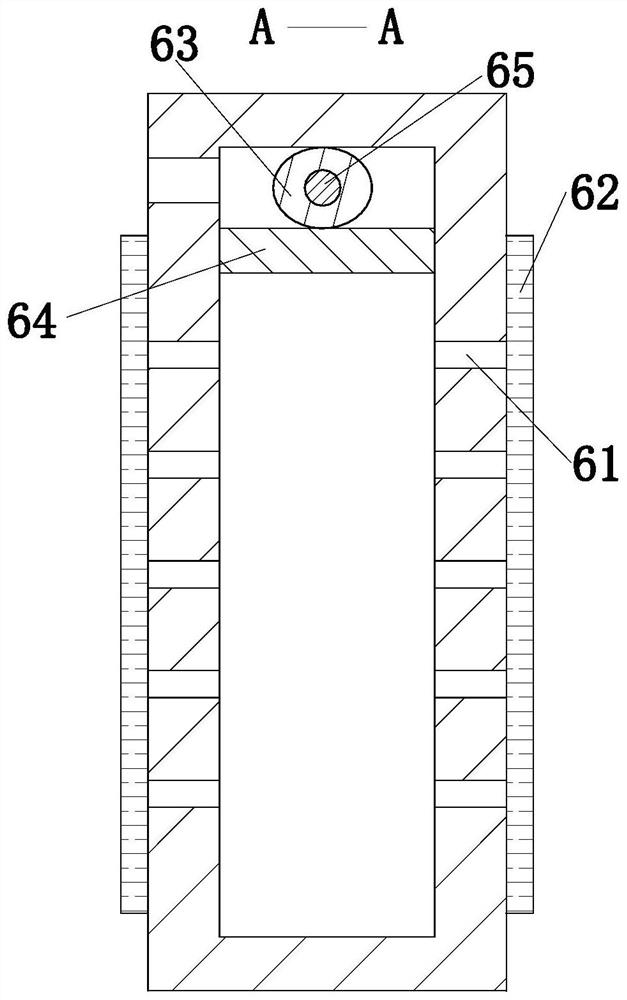

[0024] use Figure 1 to Figure 3 A factory building fire prevention method of the present invention is described as follows.

[0025] Such as figure 1 with figure 2Shown, a kind of plant fire prevention method described in the present invention, this method comprises the steps:

[0026] S1: The partition boards required for the roof and internal walls of the factory building are made of fire-proof insulation boards, which are used to insulate, heat-insulate and prevent the factory buildings. The fire-proof insulation boards include foam insulation boards, fire-resistant rubber and steel plates;

[0027] S2: Open multiple blind holes 2 on the outside of the foam insulation board in S1, place compressed spring 2 in the blind hole 2, use hot melt adhesive for the spring 2, and place cushion pads on the outside of the spring 2 in the blind hole 2 , the buffer pad is connected to the bottom of the second blind hole through the second spring; after the fireproof insulation board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com