Filter screen, filter device and manufacturing method for filter device

A filter device and filter net technology, applied in the direction of separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of low overall strength of the filter element, low bonding strength of glue, and long baking time in the oven, etc., to achieve Not easy to wrinkle and crack, easy to install and transport, and reduce the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

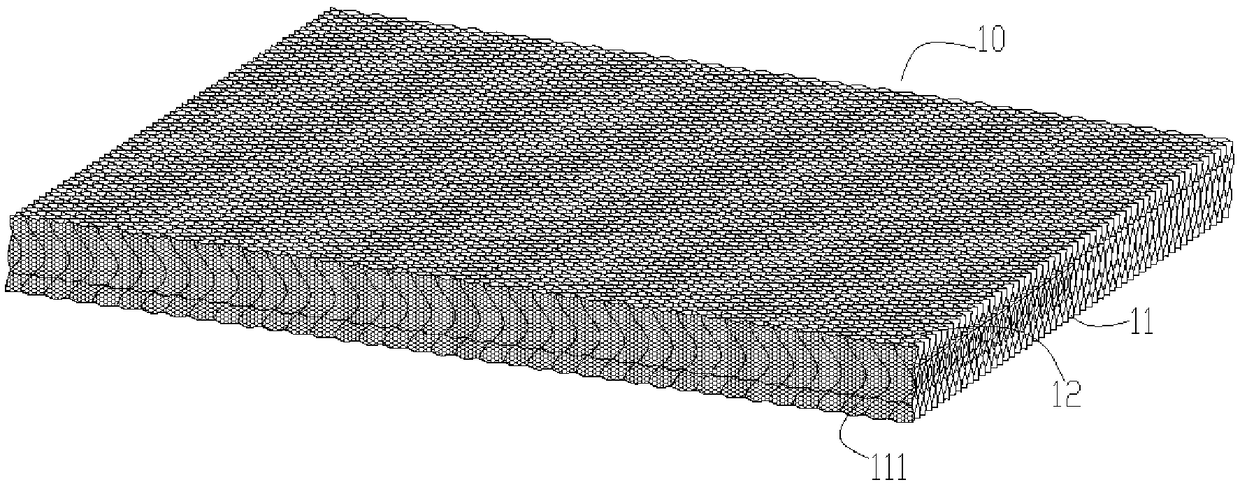

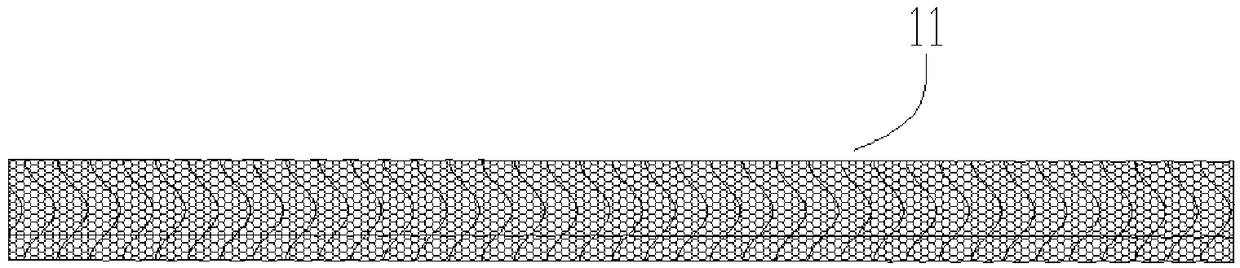

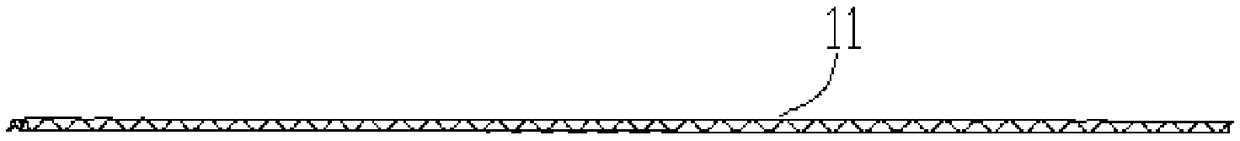

[0046] refer to Figure 1-3 , the present embodiment provides a filter screen 10, comprising laminated multilayer corrugated mesh sheets 11, each layer of the corrugated mesh sheet 11 is pressed from a wire mesh with mesh, and each layer of the corrugated mesh sheet 11 includes A plurality of curved grooves 111, each layer of the corrugated mesh sheet 11 includes a plurality of crests and a plurality of troughs, the crests and troughs between each adjacent two layers of the corrugated mesh are arranged oppositely, each Two adjacent layers of the corrugated mesh sheets are fixedly connected by welding, so that a plurality of curved filter channels 12 are enclosed between each adjacent two layers of the corrugated mesh sheets.

[0047]The shape of the curved groove of the corrugated mesh sheet is cosine linear, and the wire mesh is stainless steel mesh, so that its thickness is much higher than that of the stainless steel mesh for gas-liquid separation and oil removal. , The nu...

Embodiment 2

[0051] refer to Figure 1-4 , a filter device, comprising a frame 20, the frame 20 is provided with an accommodation cavity, the front of the frame 20 is provided with an air inlet communicating with the accommodation cavity; the back of the frame is provided with a The air outlet connected to the housing cavity; also includes the filter screen 10 described in embodiment 1, the filter screen 10 is arranged in the housing chamber; the inlet of each filter channel of the filter screen 10 is all towards the air inlet, filtering The outlet of each filter channel of the net faces the air outlet.

[0052] The air inlet is provided with a metal grid 30, and the air outlet is provided with a metal grid 30, so that the overall strength of the mesh surface is greatly improved, and the obstruction to the airflow is minimal. The metal grid 30 is a stainless steel grid.

[0053] Four oil dripping holes 23 are respectively provided at the four corners of the frame body 20 .

[0054] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com